Wm Cook

posted this

24 December 2022

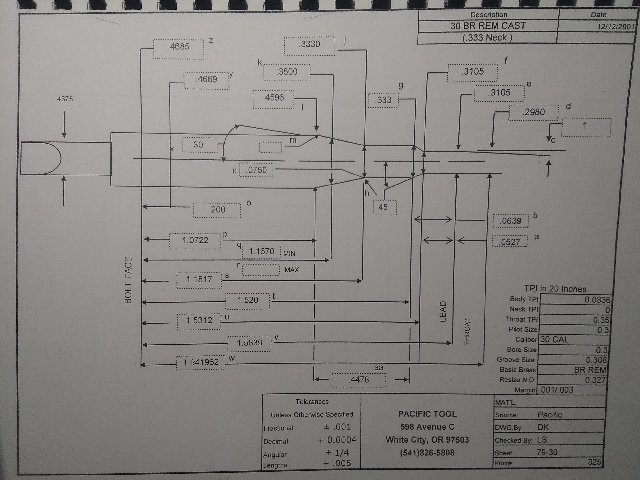

I'd call Dave Kiff at Pacific Tool and Gage and have a conversation with him. He'd have an opinion on the neck cut and if you send him a couple dummy rounds he'll probably be able to work up a drawing for you to look at. But I would recommend designing the throat to something other than the 311299 look alike.

As long as the bullet nose fits the barrel bore Bore Rider designs are super friendly to load and they don't give you the bullet to lands interference a ball seat or tapered design would when you start to look to have the gas check sitting in the bottom of the neck rather than in the shoulder. Full disclaimer; rigs can shoot very well even with the bullet below the neck but since you're starting out with a new barrel, reamer you might as well get the throat right and still keep the bullet in the case neck.

And it would be nice if the bullet you send them will kinda fit the norm for a custom barrel, assuming a .3000 bore. I have a 31-220G taper design that drops at about .3002 at the nose and about .3062 in front of the driving band. If you need a few to work with let me know. Everything else I have is oversized to fit the oversized bore I'm working with.

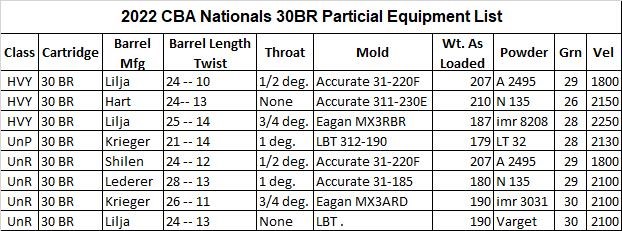

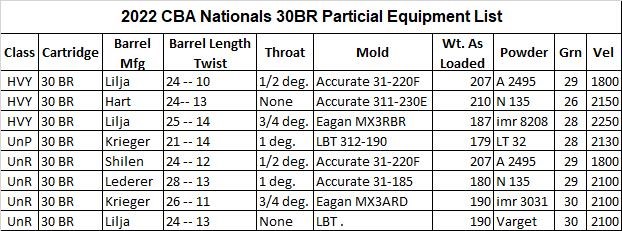

The results from the CBA Nationals will give an idea what others are using. There's a couple Spitizer with most others either Egan design or the straight taper from Accurate.

I'd be careful about running a tight neck. Jacketed br shooters run .0005 per side but they don't hand size alloy cast bullets that have a gas check pressed on the base.

I'd be great if others would chip in regards to throating and tight necks.

A “Measured Response” is as effective as tongue lashing a stuck door.