John, I’m assuming that the objective is to reach absolute match accuracy with one rifle, one bullet and one powder. That predetermines the requirement for match grade casting, reloading, bench equipment and practices.

If you only have one mold and one powder for an over the counter newly purchased production bolt gun it seems to me that the only variables remaining are alloy, lube, what size lube/sizer die, the size of the neck bushing you’ll use, the bullet seating depth, and finally the powder charge. I don’t think primers are critical so I’ll avoid that

As you know I’m new to cast accuracy but I’ll give this a shot (pun intended).

I’d first pound cast to get the chamber, free-bore, leade measurements. Then I’d use a small bore gage to get the bore diameter (I am incapable of measuring land tip to tip). I would verify the pound cast by tapping one of the cast bullets through the chamber and into the free-bore and into the lands (tapered design) or into the bore (bore rider design) removing the bullet by tapping from the muzzle. Obviously look for land marks on the bore-rider but I would focus on the free-bore length and diameter.

Either with a bore-rider, tapered or spitzer design the size of the die for the lube/sizer would be determined from the above work. At this point in my understanding cast accuracy I would size the bullets to a scrape fit into the free-bore for the reason that I want the gas check of the bullet to ride in the case neck of the brass so after chambering, the front driving band will be in both the case and in the free-bore so that the gas check is held by the case mouth.

Example: .308 Winchester has a case neck of .303. I would like the gas check to seat no further than .303 - .310 below the case mouth. My gas checks are about .015 in height.

With a Spitzer or tapered design you either live with what length you have available in the free-bore, leade and let the gas check protrude below the neck or you push out the lands. In the perfect world I would want the lands far enough out that the gas check is as I described and the bullet nose was just sticking in the lands.

I would like enough contact between the bullet and the lands that it sticks, but not enough contact that the round cannot be extracted without pulling the bullet. This “touchy feeling” thing determined the case neck bushing. Not a death grip on the bullet, just a modest grip and if the lands are broomed off a light or very light grip.

Linotype for the alloy and the Carnauba Blue for the lube in my sizer should work with the pedestrian velocities I’m shooting.

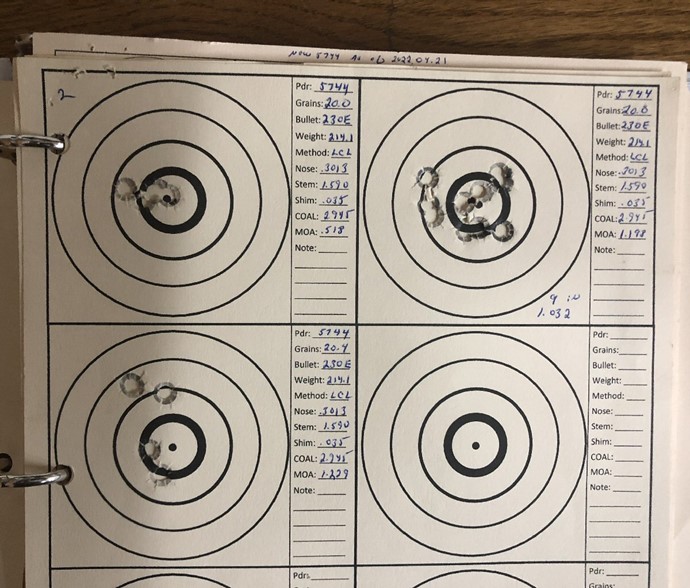

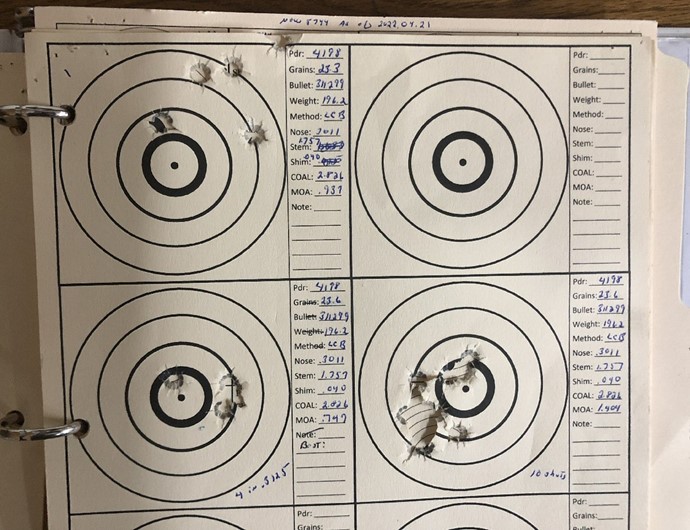

With the restriction of having only one choice for powder I’d have three powder charges worked up that would give me about 1700, 1740 and 1780 fps. I’d shoot one 10 to 20 shot group at each velocity and my guess I’d have it close to being all it can be. There may be some jinking up and down with powder if what I started with looks ugly but with one powder you’re at a disadvantage.

I would greatly appreciate yours and others critical thoughts on what I sketched out. Thanks, Bill Cook.

A “Measured Response” is as effective as tongue lashing a stuck door.