Greg,

Just a little more feedback to your original question.

I shot 50 paper cartridges through my 1859 Armi Sport Sharps carbine yesterday. They were a mixture of the homemade paper cartridges and the cardboard tube cartridges.

I had read that nitrated or combustible paper was not required when making cartridges. I confirmed that yesterday. Every round fired, whether made from tracing paper, curling paper or cardboard. The cardboard ones were a bit amusing, because you would get a bunch of confetti coming from the bore upon each shot.

I had super glued my Christmas tree bullets into the cardboard tubes. I had used Elmers white glue on some of the cartridges, and fast set craft glue on others. All worked well.

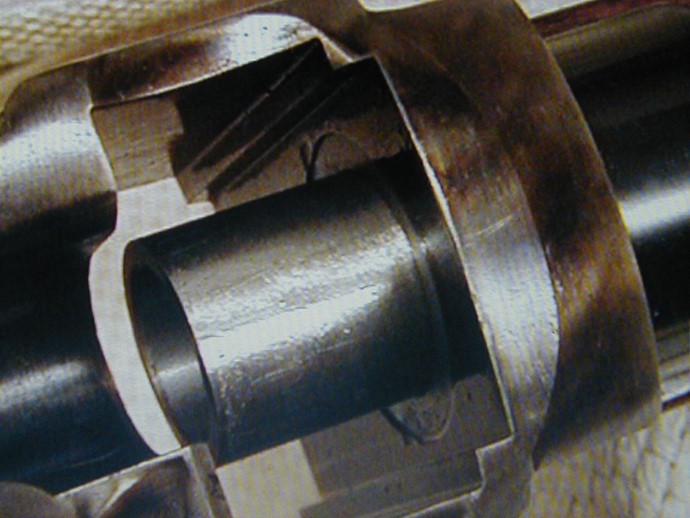

As I said, I shot 50 rounds and only ran a wet patch and then a dry once about the mid point of shooting. My chamber looked like this at the end of shooting.

The Christmas tree bullets that I dip lubed were much more difficult to load as the chamber fouled. And the curling paper that I used as cartridge paper for the dipped bullets tended to disintegrate when trying to insert the cartridges into the fouled chamber. Granted, the cartridges were formed in 2014, so I suppose the paper may have deteriorated in strength some since then.

I was surprised that the potency of the 40 grain loads formed in 2014 seemed on par with the ones I loaded a few weeks ago. I have always read that BP was very hygroscopic, and I was curious whether they would fire after all these years. They were stored in my air conditioned reloading room in a plastic cartridge box, but this is Houston Texas after all. But they all fired just fine.

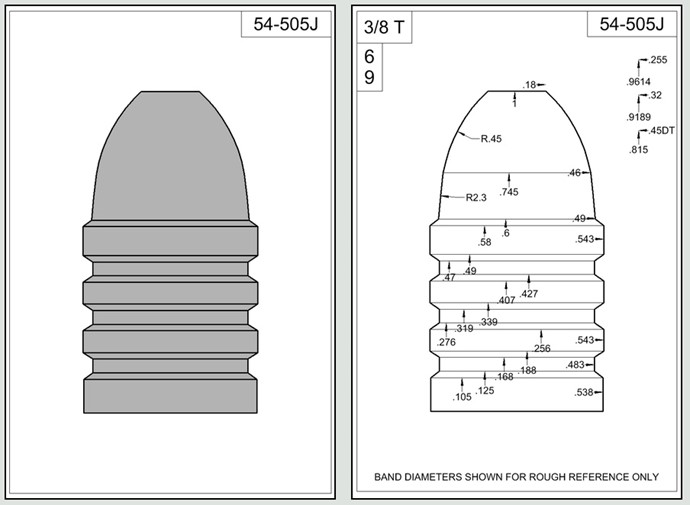

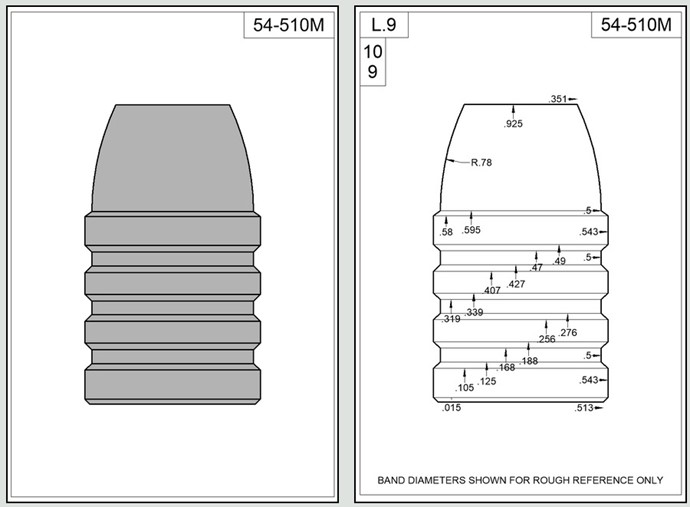

The Christmas tree bullets glued into the cardboard tubes were very easy to load into the fouled chamber in comparison. Being stiff and slightly smaller than the bore diameter, they were easy to insert. The bullets for these cartridges were lubed in my star lubesizer with my homemade SPG copy. They shot very well. I used curling paper to cap the breech end for all of these cartridges, and the fire from the cap seemed to penetrate these well.

The cardboard tube cartridges are super simple to assemble. I just dumped the powder from my Belding and Mull visible powder measure into the tube that I had already glued the curling paper end cap on. A quick swipe with the glue on the button of the bullet base, and insert it into the tube and you are done.

The tracing paper I used for the Lee hollow based mini bullets worked well. It was considerable stiffer than the curling paper, and combusted just fine. The tracing paper is by far, much easier to form the cartridges with as well. I shot them up early in this exercise, so the chamber wasn't as fouled, but they loaded easily.

As I mentioned in my previous post, the first time out with this carbine it fired twice, and then I couldn't get it to fire again. So this was the first real outing with my carbine. I imagine I have much more to learn about loading for it. But I can say that I like the Charlie Hahn chamber modification very much. It was also much easier to clean the breech block and chamber than the original configuration. You did not seem to have any issues firing your rifle, but I just wanted to provide feedback about the modification for others that may have had issues like I did.

I was impressed that I could keep firing again and again, even with all the fouling in the chamber and barrel. I have been shooting cap and ball revolvers for 40 years, so I am no stranger to the problem of BP fouling. And to keep shooting my Shiloh Sharps 45-70, I had to keep a blow tube and range rod nearby. But this little carbine kept firing and accurately too.

I had the front sight filed down to hit right on at 50 yards in about 20 shots. So I shot the rest of them banging steel plates at 50 yards and popping soda cans at 25 yards. Even the 50th shot popped a soda can at 25 yards. I really did not expect the accuracy to be there, even if I could still chamber the cartridges. Especially since I was not wiping or blowing the bore between shots.

And I loaded all of these rounds to sit flush with end of the chamber. That worked well. Some of the dipped bullets with the curling paper bodies did not enter the chamber fully as the gun fouled, and the ends were sheared off as you mentioned in your first post. That works, and it shot fine. But it makes a mess of power residue all over the nipple, the hammer and where the Lawrence pellet feed used to be and is now just a lump of metal. No big deal, but more to clean up after the end of the day shooting.

I was also impressed by the Christmas tree bullet staying vertically in line with the target bullseye as the power charge changed. The windage was perfect. The Lee Mini's were shooting a good 4" to the right of the target. But of course that is just the case in my specific carbine.

So in summary - I found that I did not have any problems shooting non nitrated cartridge paper, loading them chamber length worked fine, the Christmas tree bullet carried enough lube to keep shooting accurately even as the gun became very fouled and that I really enjoyed shooting this carbine. I felt like a kid on Christmas morning - it was just that much fun.

I may try using cigarette rolling papers next time for the end cap. The ladies curling paper that I bought was very textured and sometimes made a bit of a glue mess on my dowel when inserting them. The glue goes through the pattern on the paper so you have to keep your forming dowel wiped clean.

The silver HVAC tape that you see people using on their cartridge forming dowels to build them up to the proper diameter also helps in releasing the paper from the dowel. Very useful.

I did have about 6 misfires during the shooting. I was using RWS musket caps. They may not be hot enough, but this was my first time really using them so I have nothing to compare them with. It also may have been a bit of crud or something in the firing path in the breech block because the misfires only happened in the first 15 rounds or so - and then the carbine fired 100% after that.

Hope some of this feedback may be of use to you.