Several decades ago I made a sprue plate to fit the Lyman 2-cavity moulds, with smaller than factory sprue holes. Most recently I had it on a #225438 where the .095" holes made much nicer looking bases than the .150" factory sprue plate did. I decided I wanted to put it on my #225415 that I bought used maybe 10 years ago. Digging thru my mould toolbox I finally found it. Had trouble locating it because it's a 1-holer. Bummer. Surely a 2-cavity plate won't work on that.

I rough measured the distance from the sprue plate screw to the closest sprue hole and it looked like it was about the same on the 1 and 2-cavity mould, but at a different angle. Well, we might be able to work around that.

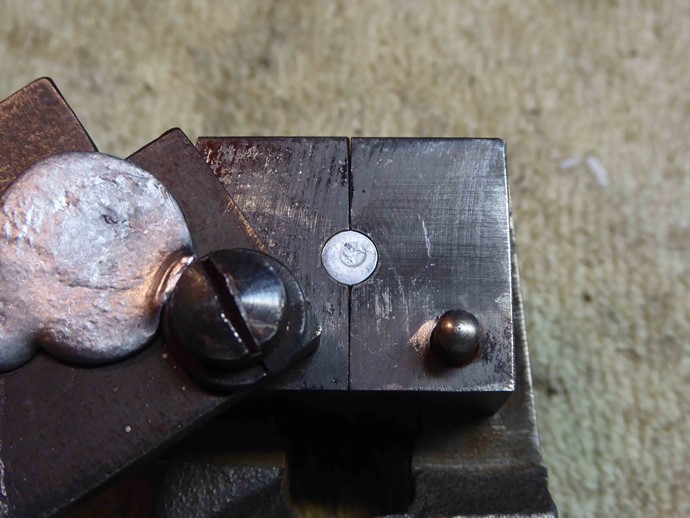

I attached it to the 1-cavity mould and lo and behold, the sprue hole was pretty well lined up when the corner of the plate hit the stop pin.

A little off center, but not too bad. A little filing on the corner of the plate might help a little. Still a vast improvement. However, I soon found out that if I let alloy spill into the front sprue hole it locked the sprue to the plate, until I cut the excess off with a pair of miniature side cutters.

The bullet ended up being a little long for my 16-twist 22 Hornet, unless the velocity got up to 1900 f.p.s. or so.

Glenn