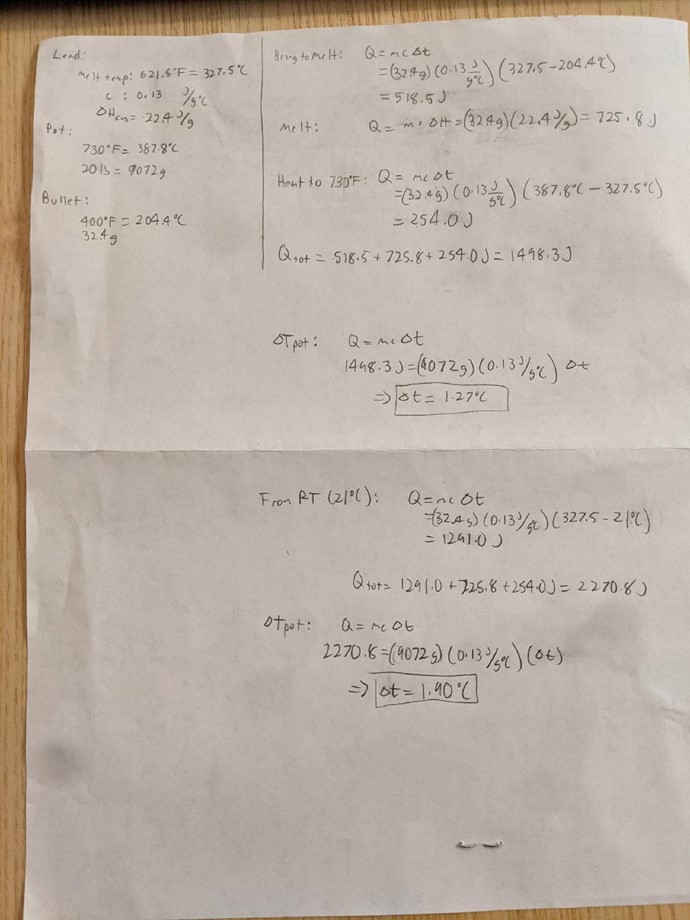

I’ve seen posts occasionally about temperature variation caused by adding sprues and reject bullets back to the pot during casting. The variation I see on my PID set-up with a 20-pound pot appears small but the issue did make me curious as to what the effect on lowering the pot temperature really was. I asked an engineer with thermodynamics expertise to do the calculation using 20 pounds (9072 grams) alloy in a pot at 730°F (387.8°C) and 500 grain (32.4 gram) bullets, one at 70°F (21°C) and one at 400°F (204.4°C). My routine, which only takes a few seconds is to drop the sprue back in the pot from the cut so it is still hot, drop the bullet on a towel, roll it looking for defects, check the base and either keep it or drop it back in the pot.

The bottom line is that putting a cold bullet back in the pot drops the temperature 3.42°F. A bullet cooled to 400°F only drops the melt 2.29°F. So if you want to maintain a temperature ±10°F and your PID is holding the pot at ±3°F then one bullet and sprue will not be a problem. Hopefully your bullet quality is high enough that you don’t have to consider this often. You can extrapolate from these numbers for multiple bullets, a smaller or larger pot with different weight bullets. labop