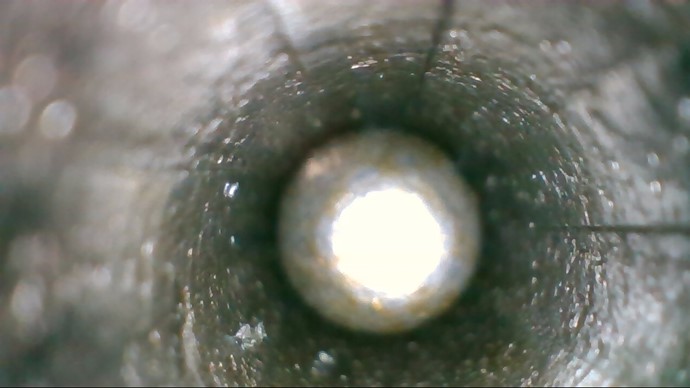

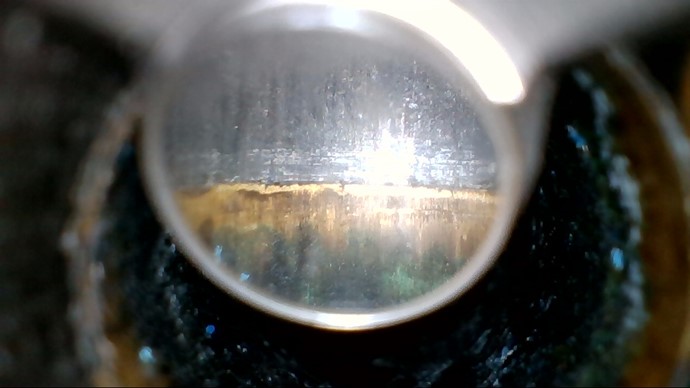

At the moment I am trying to clean the lead out of a 110yo leade which has been baked on since WW1. So far I've done pretty good but I am stumbling at the last post.

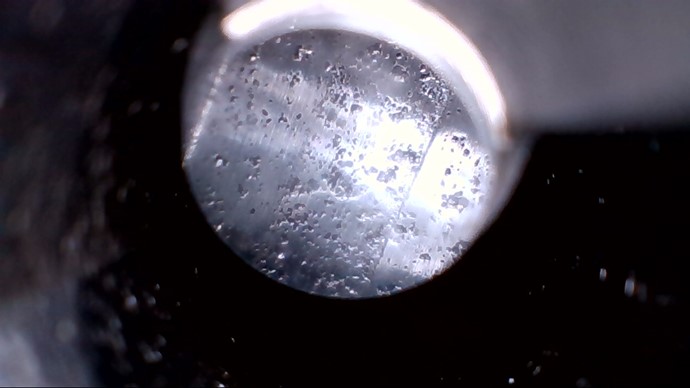

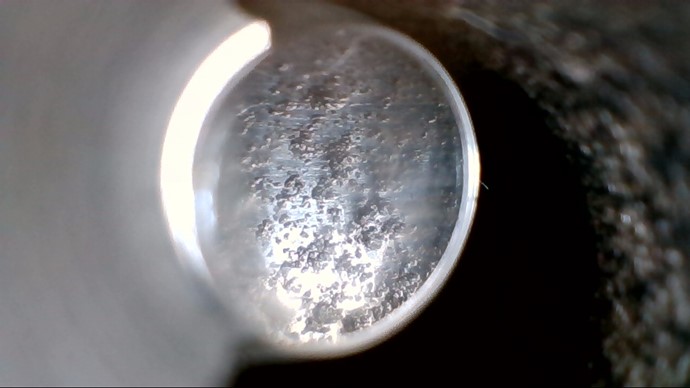

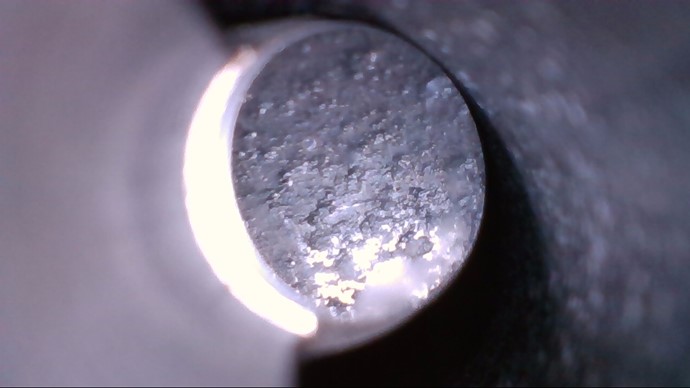

Now this is pretty good considering what I started with.

I have tried all manner of brushing, soaking, scraping, everything from Ed's Red to Mercury and as any Aussie knows if there is a stubborn smear - out comes the Sweets 7.62, if that doesn't shift it then it's going to be difficult. My first question to the brains trust, has anyone tried the Acetic acid/hydrogen peroxide soak method? I know the dangers but if you could see the leade you would understand why I ask. Short bursts of soaking up to 2 mins max and plenty of scrubbing/oil after.

So that is the boring bit out of the way.

I have 3 moulds, one came with the gun, an old 125n CBE mould with a weird heel that tapers at the driving band making for a loose fit in the case. A 130 gn pointed and 120n round nose. The projectiles measure 125 -.706, 120 - .650 and the 130 - .723

as can be seen from the pic, they are of course different lengths which is what is causing concern for me, hence the conundrum.

My cases in the chamber fit up to the start of the leade so all of the projectile outside the case must fit into the leade as there is nowhere else to go.

Which under normal circumstances isn't an issue, except when you see the loaded cases.

With an overall length of 1.540, 1.480 and 1.640 respectively

both the 120 and 130 gn projectiles will not chamber fully (unless I "persuade" them) and have done with successful groups. Which is probably due to the nose diameter, the 125 has a narrower nose diam. allowing it to fit further into the leade.

but I really want a round that will drop into the chamber and allow me to close the action without having to use a mallet. I have not really tested the 125n projectiles yet as I felt that a wobbly projectile with no case tension is not going to perform that well. I have possibly overcome that issue by wrapping PTFE tape around the heel so there is now a tight fit in the case.

So here is the conundrum.

I know that the 130gn projectiles will shoot reasonable groups at present, and would probably shoot better groups if I didn't have to force them into the leade/barrel.

The 120gn projectiles are still an unknown as they are yet to be tested, but will still need forcing. As are the 125gn but without the forcing.

I haven't trimmed a case in over 40 years and don't want to start now if I can help it. I only have 100 cases but the daunting task of trimming them is making the hair on the back of my neck stand up. That and I would have to find my case trimmer, if I could find a 32 S&W trim die I could probably make it work but RCBS stopped making them some time back.

So gentlemen, thoughts and considerations.

Tony