The alloy shootout has begun!

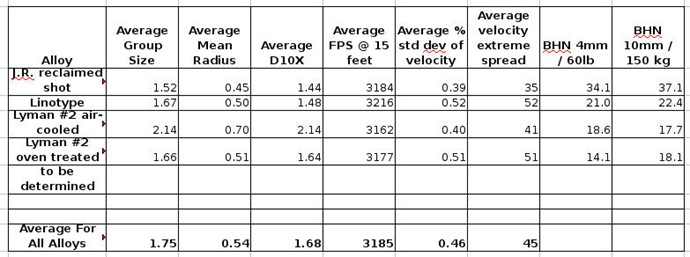

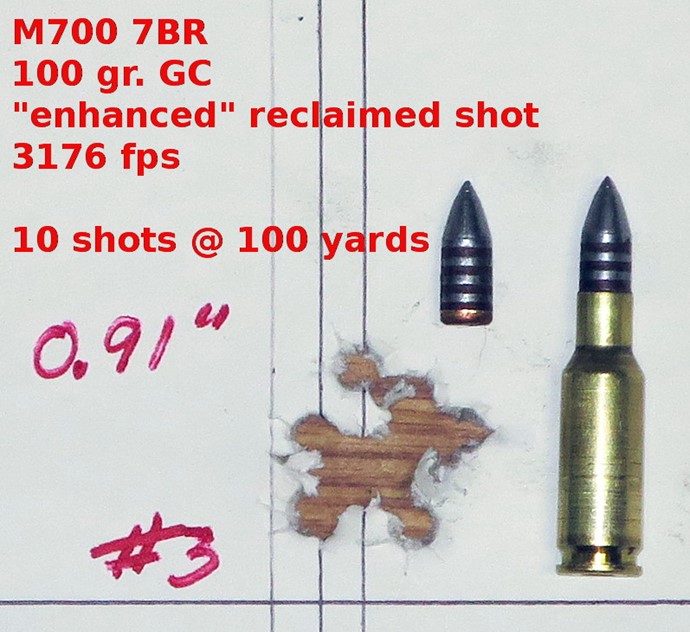

This will use the same 7BR rifle and the same 100 gr. GC bullet that I used in my lube shootout, but just for the learning experience I will be using a different powder, LT30, and driving it a little faster.

I did some last minute load tweaking. I figured the hotter load might benefit from a more positive bullet fit, so I experimented to see how far out I could seat the bullet before it would get pushed back into the case. It turned out that it could tolerate 0.020” jam before the bullet began to slide back into the case, so I used 0.020” jam for the ladder test.

I am not a big fan of ladder tests because they do not commonly take into account random variation. Nonetheless I tried a ladder test, walking the powder charge up in 0.2 grain increments. All but two charges went into one ragged hole. Were the two outliers due to their powder charge, or were they due to random variation? We can't be sure without repeating the ladder test 10 or so times, so the ladder test was not very helpful. Nonetheless I settled on the top charge of 32.4 gr. because it went into the main group and I am a s**ker for more velocity. :D

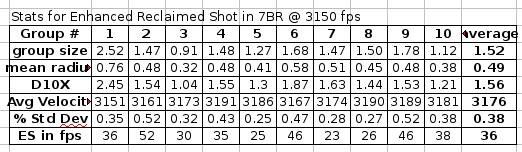

A faulty extension cord caused my chronograph to conk out in mid-test so the velocity data is incomplete. But with this load I'm not overly concerned about chrono data because LT30 has been burning very consistently (though a bit dirty), with 30 - 40 ES being typical for 10 shots.

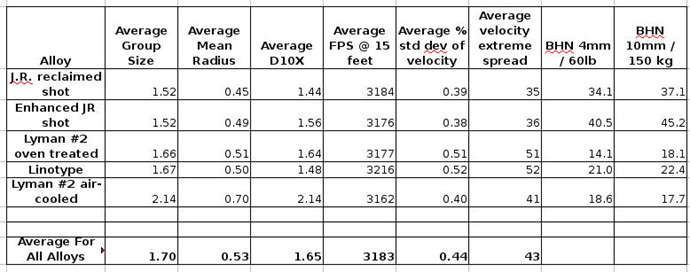

This will be the control load that other alloys will be compared to. I would have preferred a more accurate load, and in hindsight I might should have slowed it down to 3100 fps, nonetheless 1.5 MOA is accurate enough for comparison purposes. The fact that the RPM/velocity seems to be borderline for accuracy may actually be useful for alloy testing purposes, because the alloy plays a role in both the as-cast balance of the bullet and the as-fired balance of the bullet.

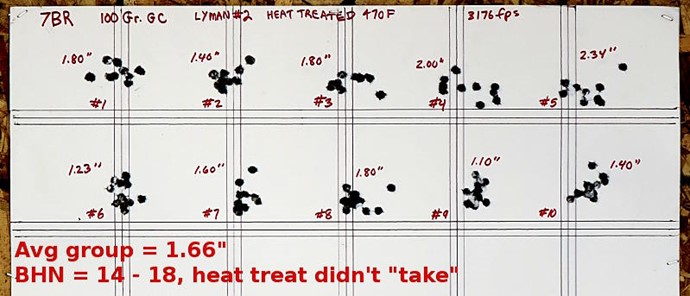

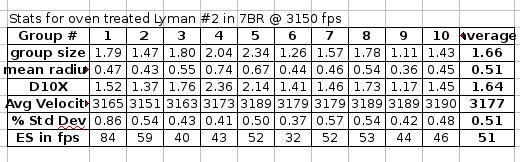

In case you were wondering, the group measurements posted on the target were measured in the field with a ruler while the group measurements in this table were Taran results. Sometimes the Taran measurement is a few hundredths different than the ruler measurement -- that's just normal measuring tolerances.

- #Permalink

- 0

- 0