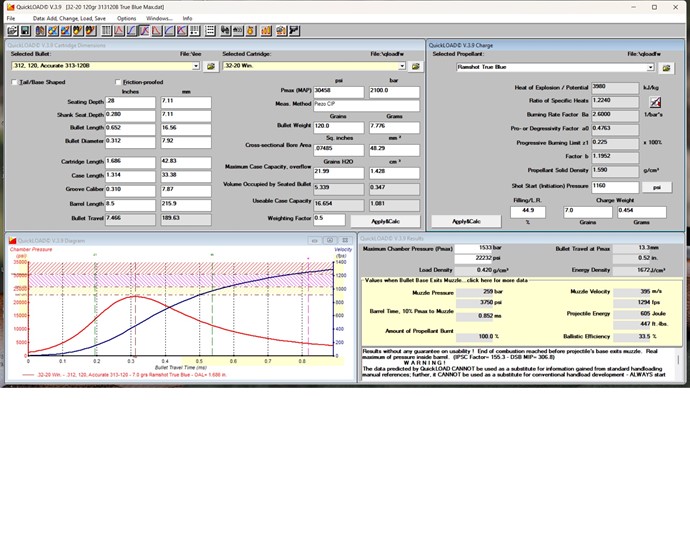

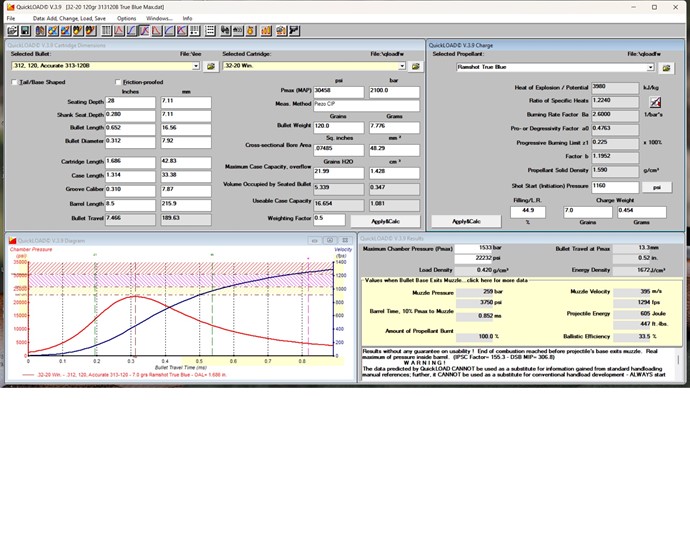

Barrel length must be tweaked to get correct "bullet travel" number. The software doesn't know about cylinders. Make barrel length inclusive of cylinder length to get close then tweak it for correct bullet travel length. Remember that some bullets set farther back in the cylinders too.

When picking a cast bullet, I use the Lee bullet file and then correct the data for the actual bullet (Accurate Mold) I am using. Shank length is important as is seating depth. Incorrect seating depth in high intensity cartridges will wreak havoc with your calculations. It must be correct since .10" in a 9mm can almost double chamber pressure depending on propellant.

My 32-20 loads with a 120gr cast bullet are very accurate calculations if you have the bullet measurements and seating depth correct.

Heavy crimps can alter the "shot start" pressure which can also wreak havoc with calculations. Since we don't know shot start pressure, we must accept defaults. If you have a heavy crimp, you can play with shot start pressure to affect MV that you record. Remember that V at 10 feet, is NOT MV.

Those are some of the things I play with. It's very neat software!

Notice to get the bullet to show travel in a 7.5" barrel for real, I had to specify the barrel length was 8.5" to get the travel length correct.

With rifle in hand, I confidently go forth into the darkness.