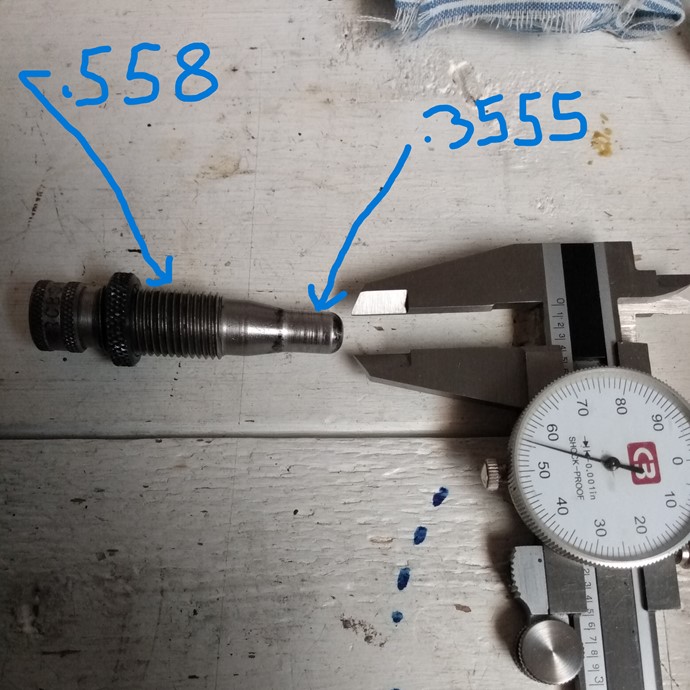

This is about reloading lead and powder coated rounds for my Rossi 357 rifle. I use an old set of RCBS steel dies. The expander ball measures .3555". Not having pin gauges, the nearest I can tell, that die produces cases with an I.D. of .355".

Normally, for lead loads out of a 357, you would size to .358". Well, my Rossi shoots best with boolits sized to .3565". That's what my tightest sizer die produces.

I'd like to experiment with cases with a larger I.D. My questions are: Can I purchase a larger expander for this die? My other question is, if I got on a lathe and made an expander, what size threaded rod/bolt would I make it out of? The threads on the expander measure .558". I couldn't match that up to an existing thread size.

Hope that makes sense. Here's a pic of the expander:

.jpg?width=20)