JimGnitecki

posted this

07 November 2023

In prepration for today's range session, I analyzed my bullet quality as objectviely as I could. As I am still an amateur in bullet casting, my Extreme Spread on cast bullet weight is between 0.9% and 1%. My standard deviation is 1.2 grains (=0.25%). I'll get better with time.

Today's range session was encouraging:

Average velocity was 1393 fps, which is about a 35 fps increase versus the softer heavier bullets that were cast with softer alloy.

At 200 yards, the Labradar said they were still reliably supersonic, which means I'll be able to use my Shotmarker electronic tareget system with the Pedersoli rifle out to 200 yards. 225 yards MIGHT be possible, but the remaining velocity there is right around the speed of sound, so the Shotmarker might not catch some of the bullets at 225 yards.

Accuracy was improved today in 2 ways today over prior range shooting sessions:

1. The best 5-shot group fired today was 1.25" at 150 meters = 164 yards, which translates to 0.73 MOA at that range. Slowly getting closer to my target of 0.6 MOA.

2. There were no "wild" shots at all. Just groups not as good as the 1.25" group, but NO "flyers". That is a very significant improvement.

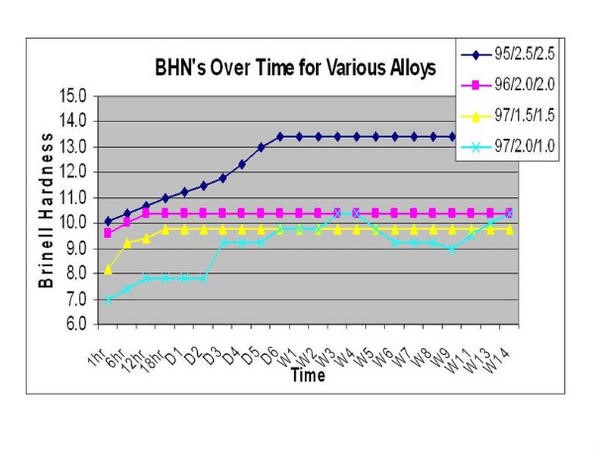

So, higher BHN did make a noticeable improvement.

This was with BHN = 16 (so far) and .459" sizing. Need to next try BHN = 20.

I will also, separately, try a batch of bullets sized to .458" versus .459", since the .459' did make a marginal improvement over the prior .460" in a prior range test, That makes .458" worth trying, and the Lee .458" sizer insert and punch did arrive a couple of days ago.

Jim G