The basic concept came from many shooters over on CB forum repeatedly stating that “Fit is King” but when looking at the bullet designs, the rifles that used them, and the reloading equipment, it doesn't take a rocket scientist to see that in application, Fit is actually deuce for most of us.

It was theorized (add nausium) that if all these things were corrected, then it would be possible to push further than the average shooter has been able to.

I simply set out to find out if that was true, and to what extent. Therefore, when I encounter a problem, or a shortcoming, I simply create a way around it since I have all the tools to do so, as well as an advanced understanding of practical precision and how to implement it.

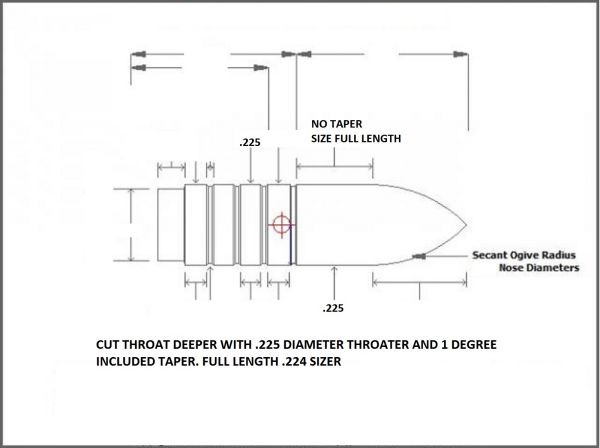

Precision starts with the barrel and how it is reamed, so I started right there and designed methods of reaming truly straight and concentric chambers and throats, and more importantly, ways to measure these things and prove they are truly what I say they are.

From there, I radiated outward to the action, and devised a way to bluprint the action while it was on the barrel, and again, provide real indicator measurments of just how well it does that. Many claim the bluprinted action is parrelell and concentric to the centerline of your bore. I can tell you how close it is in tenthousandths of an inch.

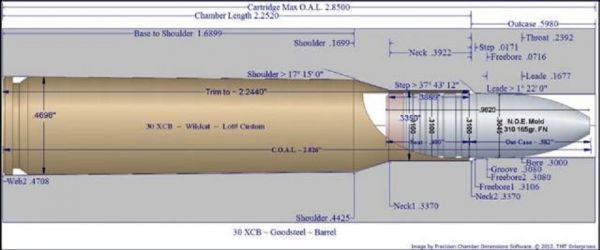

Next, I moved onto designing a cartridge that would have all the benefits of the very best cast bullet cartridges in history, none of their shortcomings, and enough case capacity to reach 3000FPS with medium burn powders.

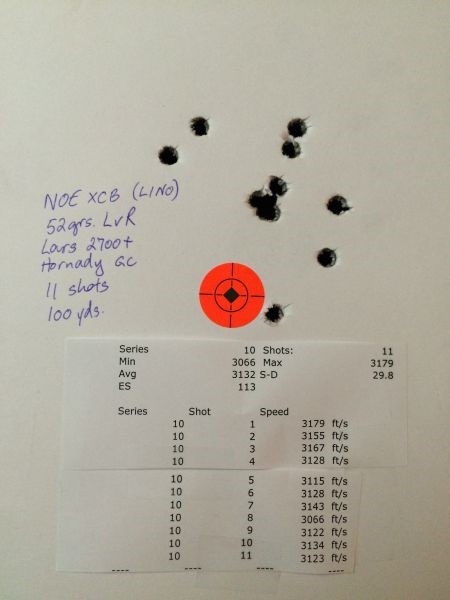

I tried to get a team of shooters together to prove the XCB (eXtreme Cast Bullet)concept up to this point. I built them rifles and reloading equipment, and anything else they might need in order to make this happen. Some were unwilling to prove the concepts as agreed apon (the castboolits affliction) but fortunately new shooters stepped up to the plate to lend a hand, so the project didn't die in it's tracks, and testing continued with new life.

At this point, the bullet that was leading the pack was the venerable 311466, but even it was failing much earlier than I thought it should have, and I recognized serious design flaws in that bullet when applied to HV cast shooting. Once again, if FIT is truly KING, we were not walking the line very well, so I set about to point my energy at a new bullet design, thus the NOE XCB bullet was born (as referenced above).

At this point, I felt that the XCB project had outgrown the forum it was started on, as we could not seem to make it very far without getting inundated with comments by people who (for whatever reason) will not back up their theories with the quality documentation that I demand for this project (can you blame me? I have gone to tremendous personal expense, and I'm not going to reach my goals only to have somebody call BS on all my hard work because I or the participants were unwilling to back our claims) so we accepted an invitation from Al Nelson to continue documenting the XCB project on his website (he helped design the bullet afterall).

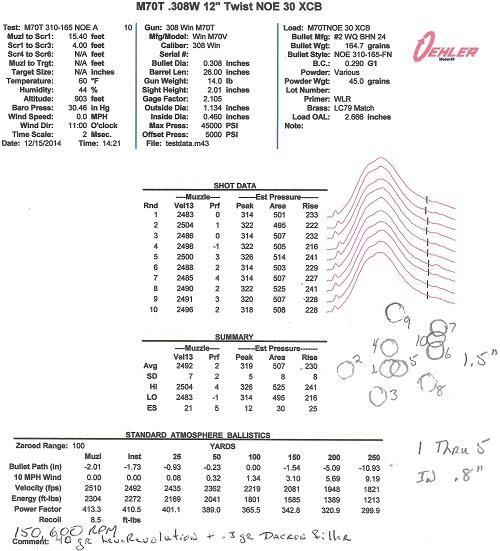

At this point, we were still doing amazing things with the XCB project, but it was still bothering me about the launch of the bullet and that unseen damage that happens to the bullet during that event. I know the bullet is being imbalanced as it engraves, because paper patch bullets seem to shrug off the engraving event and can be pushed to 3000FPS with accuracy. Thus I knew the bullet was not inherently imbalanced as it drops from the mold and something must be happening at launch. Another thing that was bothering me was that we could actually see this engraving event happening in LMG's pressure traces. There was always a little pressure spike just before the pressure swept upward as the powder gave it's energy to the projectile.

I still couldn't get past my sandbox tests which showed the bullets getting twisted as they engraved from the inertia of that event.

I decided that I wanted to eliminate that little pressure spike, and take the engraving event out of the equation altogether just as H.M. Pope had done by pushing a bullet from the muzzle of the gun and loading a charged case behind it.

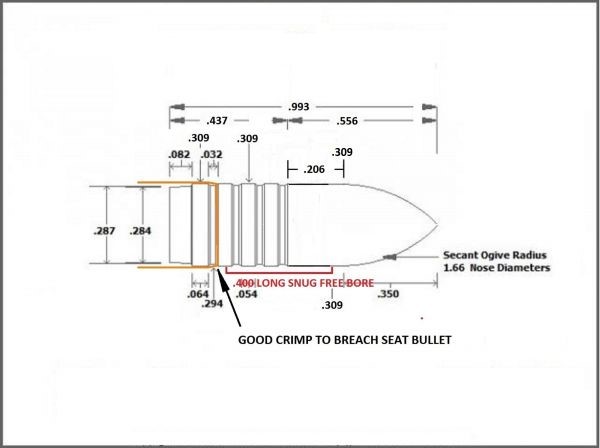

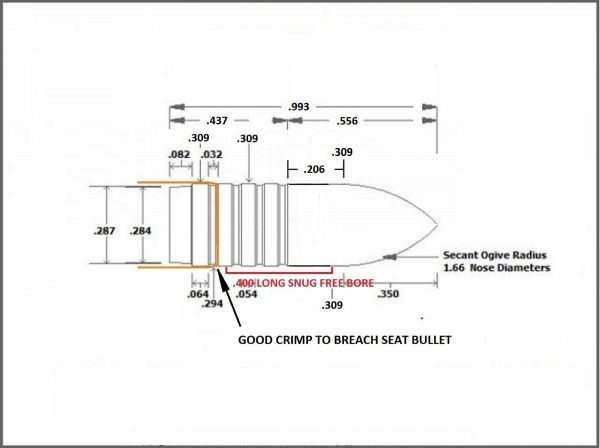

I realized the pressure needed to fully engrave a 30BHN bullet was going to be a tall order, but fully expected it to work, so I created the breach seater so that it would push the whole bullet into the rifling all the way to the GC.

In order for this to work at all like I had hoped, the bullet would have to be fully supported through this entire operation, so I made the hole that it is passed through exactly .0003 larger in diameter than the bullet itself. Any tighter than that, and the bullet would be sized down or damaged (possibly by hydraulic action of the lube in the grooves).

Once again, it seems that FIT really is KING, but I actually realized it in my breach seater. We aren't just pushing a bullet in the barrel of the rifle. We are pushing it in STRAIGHT and I guarantee that to .00015 inches.

So that brings us to the present time.

We are each moving forward with our tests and contributions.

BjornB is currently ragging out that breach seater as thouroughly as possible,

LMG is conducting pressure trace experiments on the XCB bullet with a focus on lube.

sgt.Mike is testing the XCB bullet on several 30-06 rifles, following the load procedure that BjornB has outlined as beeing successful, but he's seeing how well these procedures work in standard rifles of fast twist.

I have 4 Brux barrels coming in in various twist rates that I will build into more target rifles to help bolster BjornB's progress on all sides, and I am building an XCB rifle for LMG with several modifications, and trying to keep all the cat's herded in the right direction.

That's the best I can do to explain who what when where why and to what extent. Hope it helps.

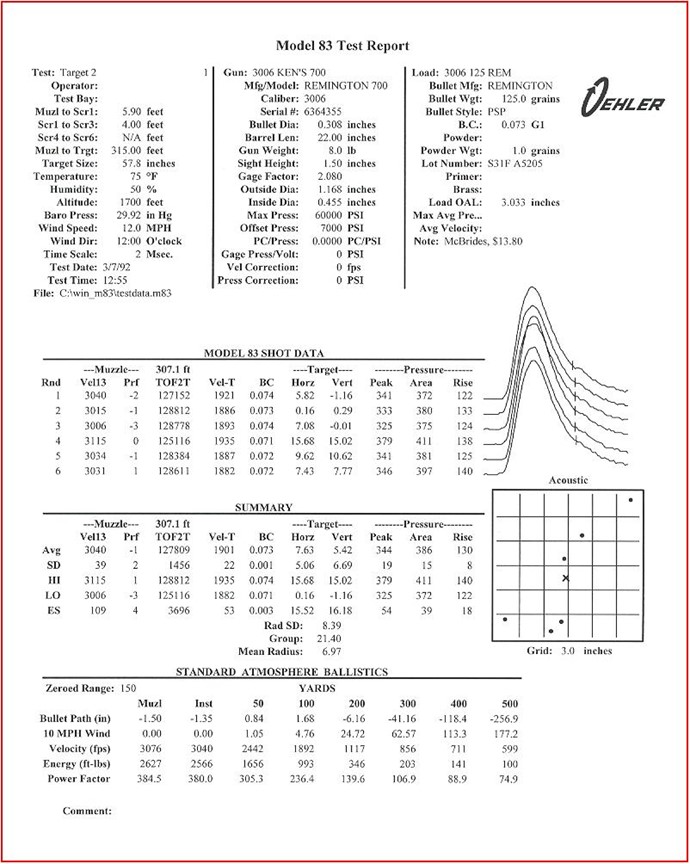

Point being, while there may be “little blips” on Larry' traces, we don't know what they are. There seems to be an awful lot of jumping-to-conclusions going on. I've done a fair amount of pressure tracing with high velocity cast, and don't recall seeing any “little blips” that might correspond to engraving. Bear in mind that the raw signal from a strain gage is very noisy, and is usually filtered by both hardware and software before it shows up on your computer screen. It can be particularly tricky for a pressure trace to capture the true point of ignition, because there is a lot of noise that can be mistaken for ignition. I.e., I often get false “ignition” if I jiggle the cable or if I close the action hard. That said, I do appreciate people sharing their shooting data, blips or no blips.

Point being, while there may be “little blips” on Larry' traces, we don't know what they are. There seems to be an awful lot of jumping-to-conclusions going on. I've done a fair amount of pressure tracing with high velocity cast, and don't recall seeing any “little blips” that might correspond to engraving. Bear in mind that the raw signal from a strain gage is very noisy, and is usually filtered by both hardware and software before it shows up on your computer screen. It can be particularly tricky for a pressure trace to capture the true point of ignition, because there is a lot of noise that can be mistaken for ignition. I.e., I often get false “ignition” if I jiggle the cable or if I close the action hard. That said, I do appreciate people sharing their shooting data, blips or no blips.