it is looking as if our near-liquid lead alloy bullets are being distorted in the first inch or so upon ignition. it is not as clear that running out of lube or stripping/gas cutting, or melting due to barrel friction after the first 6 inches is unavoidably present.

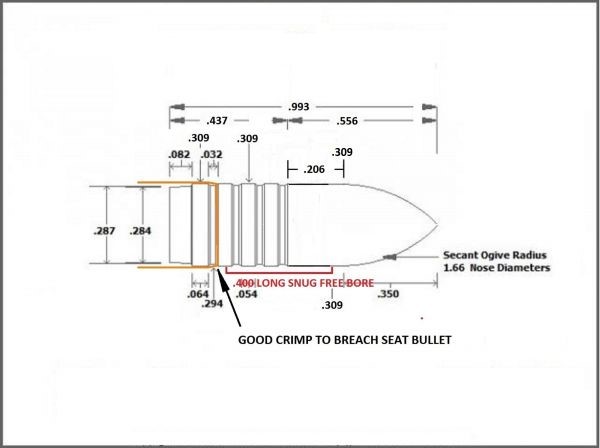

partial success in out quest to match jb accuracy is probably due to schemes to align and support as much of the bullet as we can before firing.

and probably by using as hard an alloy as we can find .. maybe the end goal would be a strong metal jacket ( g ) .

also it seems that keeping g forces lower ( thru slower burning rate powders and very long barrels ) results in less bullet deformation for the same muzzle velocity. honorable mention goes to having a high quality barrel .

the above is an attempt to pause, inspect the past 600 years of shooting lead, and see where we go from here. that we attain an easy 2 to 3 moa by following 4 or 8 rules i consider amazing !! harry pope knew these rules 100 years ago but only with the internet have the rules been so available to so many interested in improvements.

as has been dutifully noted , and with precious truth indeed ... that wonderful schemes and midnight inspirations do not make great targets without some investment of time, sweat, ...and yes often money ... still it is useful to have a few hundred possible fantasy improvement scenarios in hand for our subconscious to sort out on our road to beating the curse of cast bullets always being that other child.

so what do we try next ? accuracy with velocity is near ;;; i can sense it !!

ken