I have two IDENTICAL Cimarron Arms (Uberti) Model 94 rifles chambered in .38-55 Winchester. After filing a radius at the 6 o’clock position on the breech face, both rifles now feed ammunition without a hitch. While shooting the second rifle last week, I noticed that it simply would not open the action after the shot. It was jammed up tight.

The load is a very moderate load with Starline 2.085” (short) brass. The propellant is 28gr of IMR-3031, a Hunter Supply 260gr FP bullet, and lit off with a Winchester Large Rifle primer. This was the third such load tested in the rifle with the same result. Propellants varied on previous loads with Buffalo Rifle, RL7, A2520, and another with a propellant I can’t recall at this writing.

ALL of the loads resulted in a jammed-up action which could not be opened with normal force on the lever. To get the fired cartridge out of the chamber I had to cock the hammer and drop the hammer on the fired case. The lever could then be operated in the usual manner and the fired case extracted. Once ejected, the backed-out primers became visible. The primers are extruding at least .015” and may have been seated a tad deeper with the firing pin strike on the fired case.

A focused internet search on M94 backed out primers seemed to yield a consensus of a Headspace issue which was(is) endemic to the M94 family of rifles. Of course, there were dissenting opinions which ran the full gambit from Alien interference to dirty chambers. Rest assured, my chamber is “normal” and operating pressures are within industry standards.

I am believing the headspace argument is valid based on a few things:

- Winchester made thicker locking bolts to accommodate headspace issues in decades past. A .005” thicker locking bolt was normal and can still be purchased on various sites.

- When my bolt goes into battery, I can use my thumbnail to push it forward just enough to be visible. The locking bolt also appears to rise just a little bit too. That could be my imagination, but it does seem to rise a bit and hold the bolt forward.

- The Starline .38-55 brass I have is measuring .056” rims and not the .063” as called for by SAAMI. Not as thick as they could be, but not by much.

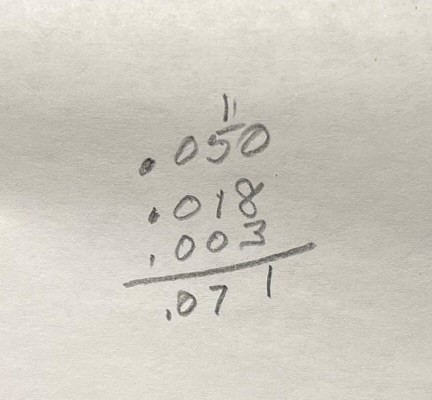

- My measurement for headspace is .071” or 1 thou greater than the SAAMI spec.

One thing is certain, the SAME cartridges fired in the first rifle DO NOT have extruded primers. The bolt on the first rifle can not be manipulated forward on that rifle either. Two identical rifles. One extrudes primers, one does not.

I have to say the headspace argument is correct although I have to admit, I do NOT see how excessive headspace will allow a primer to extrude. That case is going rearward when fired and should seat that primer flush, if anything, with the case head. I simply can’t envision it in my feeble little brain.

I may order a “Field” gauge to see if the action will close on it, but still have a few comparative tests to make before I spend even more money. I’ll try the 2.125” brass to see if it also extrudes primers. It could be the brass primer pocket with this lot of Winchester primers is incompatible. Like I say, a few more tests are in order.

Do any of you who shoot a M94 and have experienced extruded primers have any input here?

Rifle-1, Extruded Primers

Rifle-2, Normal Primers, Same Load

With rifle in hand, I confidently go forth into the darkness.