I am casting 500g bullets using the Lee .459 500 3R mold.

I am powder coating them.

I am experimenting with sizing diameter, comparing .459" and .460" sizing. I am shooting them out of a Pedersoli Sharps replica rifle with groove diameter = .4563" (slugged by a pro gunsmith).

I am trying to keep the muzzle velocity as high as possible because with a prior 485g bullet cast from a different older Lee mold, the bullet grouped 0.62 MOA at 100 yards, BUT once the bullet got into the transonic velocity range at about 150 yards, it would not group.

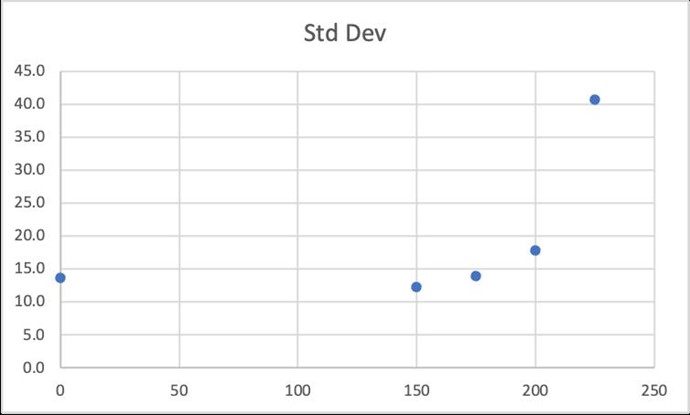

With the new 500g bullet, using Accurate 5744 (smokeless) powder at near the maximum load per load tables, my Labradar says I am getting consistent 1360 to 1375 fps muzzle velocity with single digit Standard Deviation. The load tables say that the peak pressure at this loading is 28,000 psi.

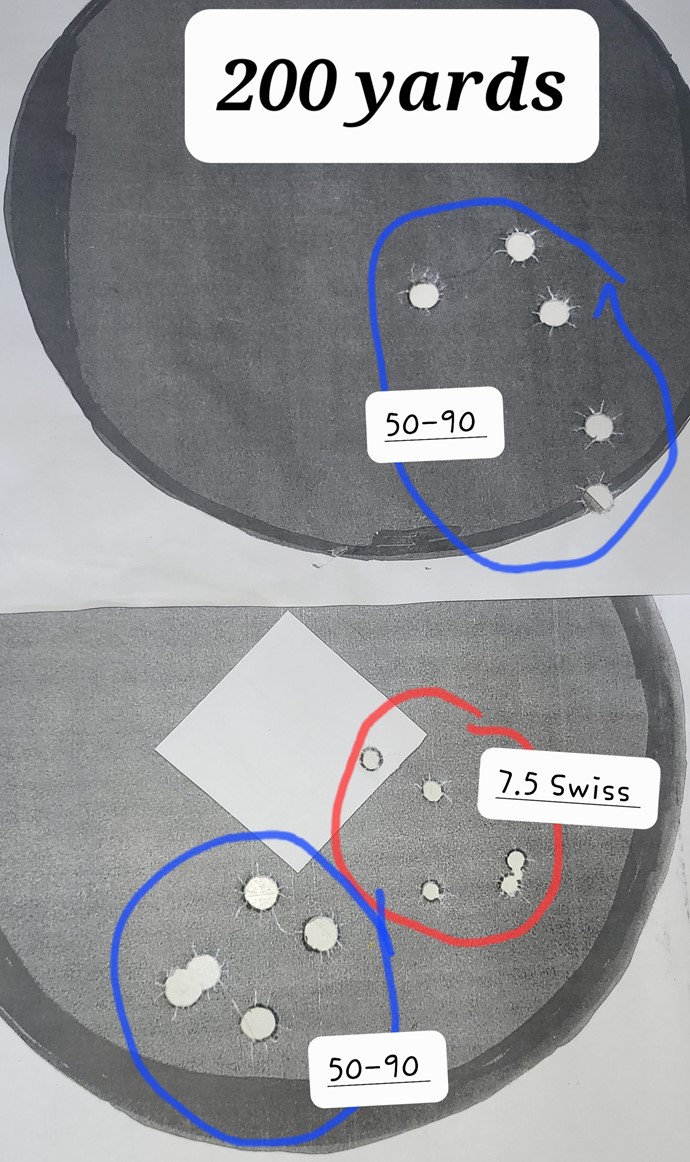

The Pedersoli groups these at 150 meters (164 yards) pretty consistently to 1.5" to 2" for a 5-shot group. At that 164 yard range, that's 0.86 to 1.16 MOA. This is "not bad" but not nearly as good as the 0.62 MOA, more lightly loaded, 485g bullets were doing at 100 yards.

I know that both sized bullet diameter and BHN affect accuracy:

I have been told that .460" sizing I have been using might be too large a diameter for the Pedersoli's .4563" groove diameter. So, I will be trying .459" sizing.

But Richard Lee said in his book "Modern Reloading" that BHN is also important for accuracy. I have so far been shooting an alloy with BHN = 10.

I have made up some test cartridges now using BHN = 12.5 and BHN = 14.5 (per my Lee Hardness tester). But, Lee's theory was that for optimal accuracy, the bullet hardness she be about 10% higher than peak pressure. In my case, with supposedly 28,000 psi peak pressure, Lee's guiding table says that I should have a bullet strength of about 110% x 28,000 psi = 30,800, which, per Lee's table, translates to BHN = almost 22! That's Linotype hardness.

I realize that pushing a 500g bullet to a muzzle velocity of 1360 fps is not a "low" pressure load anymore. But having to use Linoytype-level BHN hardness seems a little extreme. At least a couple of other buffalo rifle shooters have told me that anything above BHN = 15 is more than is necessary.

Do any of you out there have buffalo rifle experience, using smokeless powder, who can comment knowingly on what BHN is actually appropriate for best accuracy at this 1360 fps velocity and 28,000 psi pressure?

And is a change from .460" sizing to .459" sizing going to make a difference in accuracy?

Jim G