Most discussions of case life in .30-30 or .303, or similar, stress the desirability of sizing the case to headspace on the shoulder, not the rim. This of course excludes straight cases like .38-55, .45-70 and the pistol cases. What follows relates to .30-30.

If the rifle has tight headspace the process starts with firing the cartridge. The shoulder blows forward to fit the chamber. Then adjust the FLS die (or neck die) so that it does not push back the new shoulder.

If the rifle has loose headspace, like my Savage 99, the process begins with a fired (or unfired) case that has not already been stretched. My .30-30 cases mostly start life as once fired donations.

My preferred method of blowing the shoulder forward is to make circlips out of copper wire . The circlips go around the groove forward of the rim, leaving a gap for the extractor.

Since the circlip has also to fill in the bevel on the back of the chamber, and is pushed into the groove around the case, the wire diameter will be rather more than the amount of headspace to be taken up. Find some wire that is just a bit too fat, then if necessary squash to the “just fit” thickness. I used my 7/8” press for this, putting the flat faced lower part of my Lyman priming tool on the bottom, and a piece of flat steel against the bottom of a loading die on top.

Fire the cartridge with circlip and you will have the shoulder in place with one shot, or maybe two. Shoot these cartridges as normal loads. You may be restricted to single loading. For my rifle I can position the top cartridge in the magazine to feed so the extractor finds the gap in the circlip.

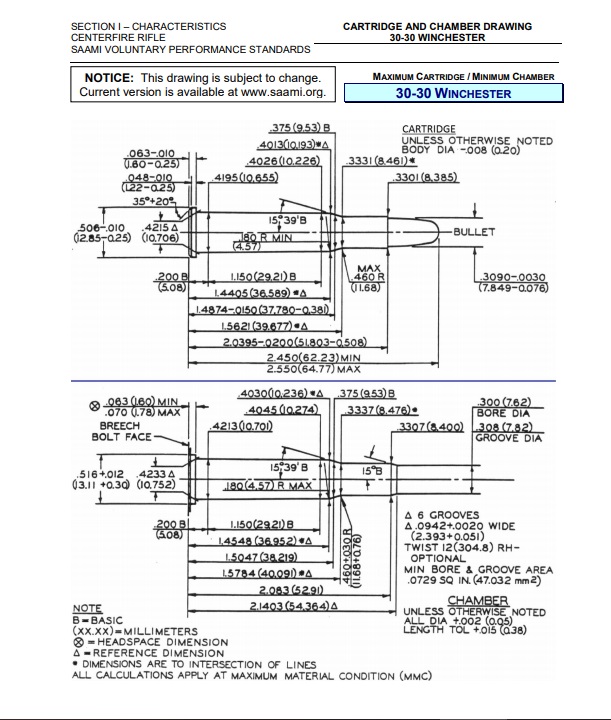

The other method I have used is to open a .30-30 case up to .375 with a series of M Dies, then size back to .30-30 with the more forward shoulder. A good smear of anhydrous lanolin around the inside lip of the neck precludes neck splitting. The case shortens about .050” on the way to .375, and recovers about .025" going back to .30-30, net loss .025”.

Larry Gibson writes of doing something similar but with expansion to just .35”.

The last method is to seat the bullet out to engage the rifling with resistance. Disadvantages are unknown effect on ballistics and (in my case) a loaded cartridge too long to eject.

To know whether the shoulder is far enough out without trying every case in the rifle, you will need a gauge. It can be simple. I use a spare .354” bullet sizing die with punch removed. I place the case or cartridge nose first in the top of the die, so the shoulder engages the lip of the die, and measure the combined height of die and cartridge with vernier calipers. With my setup 3.100” is a gentle crush fit in the rifle. New Starline cases measure 3.035”. I understand that there is also a commercial product for this measurement.