Later my plan is to shoot .38 S&W factory and handloads with various weight bullet handloads in several revolvers having different barrel lengths and cylinder gaps. Yesterday I fired .38 S&W ammo from my S&W Model 940 (9mm Centennial) which I modified "ala Ruger" so that I can use 9mm Parabellum with clips and .38 S&W without.

Because people will ask, I will describe the cylinder modification, but doing so voids the factory warranty, so you are on “your own nickel.” I hand-reamed the entrance of the .356” cylindrical ball seats of the chambers with a Brownell's .32 cal., 11-degree forcing cone reamer, increasing the major diameter of the ball seat entrances from .356” to .359.” The reamer’s .375” diameter shank serves as a pilot to align the reamer in the 9mm chambers. Before reaming the chambers are swabbed with Brownell’s Do-Drill. The reamer is threaded onto its T-handle and holding the stripped cylinder vertically, the reamer rests against the chamber stop surfaces only of its own weight, plus the attached T-handle. Using light finger pressure, you "twirl" the T-handle. The first 20 light turns produced some fine stainless steel “flour” mixed with cutting oil on the flutes of the reamer. Wiping the chambers I checked progress dropping five soft lead .358” diameter Magtech 158-grain LRN bullets into the chambers, first pushing them into the ball seats with hand pressure and then tapping each bullet solidly into its ball seat with a 2-oz. brass hammer, then I tapped them back out again so that they could be measured.

Visual inspection of the tapped out slugs showed that they entered the ball seats smoothly without shaving. Where the bullet foreparts were forced into the uncut portion of the cylinder throats, they measured .356” and on the bullet shank at the ball seat entrance they measured .3575” being lightly sized by the recut chamber throats. So I oiled the cylinder again and repeated the process, another 20 twirls around all 5 chambers. I then took the Brownell’s 3/8” ball chamfer tool to break the wire edge remaining on the reamed ball seats of each case mouth stop surface, then I slugged the reamed chamber throats again.

Ball seat entrances were now .359” tapering to .356' over about a 1/16” distance without any sharp corner at the transition from case mouth stop surface to ball seat. Factory 9mm rounds still headspaced properly without the clips and factory R-P 146-grain lead RN .38 S&Ws actually headspace on the crimped case mouth with their rims standing just proud just enough to make up the difference between the .055” thick .38 S&W rim compared to the clipped 9mm Parabellum rounds, as shown in the photo below.

The S&W 940 FIRST FIRING 9mm AMMO

CCI Blazer 115-grain FMJ - 1059 fps, 72 Sd, 245 ES! - Bullets of this ammo are not cemented into the case. Sharp recoil draws them forward, causing erratic velocities and potentially jamming the gun! A bullet protruded out the front of the cylinder, in the last round of the second clip. Loose 9mm rounds go off OK without using the star-clips and poke out easily with a BIC pen.

W-W 115-grain FMJ White Box - 1091 fps, 19 Sd, 44 ES. - Much more uniform. Bullets cemented into case with military-specification "Black Lucas" according to Winchester. Point of impact was 6" low at 25 yards. - Gun is set up for a heavier bullet. Since .38 S&W factory ammo with 146-grain bulllet shoots to the sights, next range trip I need to try some 9mm 147s and shoot into water jugs to see if they expand from the short barrel. Would be nice to use .38 S&W for practice and 9mm 147-grain for carry.

The W-W "White Box" FMJ gave sticky extraction, you gotta wear a glove to "spank the baby" if banging the ejector rod with the hand!

FIRING .38 S&W Ammo in the 940 - This really works like a champ after the "Ruger Cylinder Mod," described above. Factory ammo shoots to sights and more is accurate than firing 9mm FMJ.

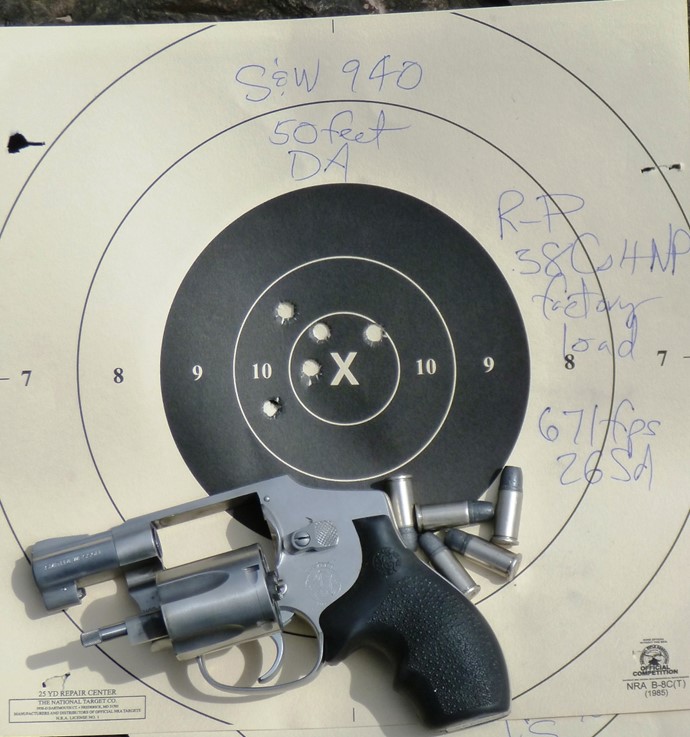

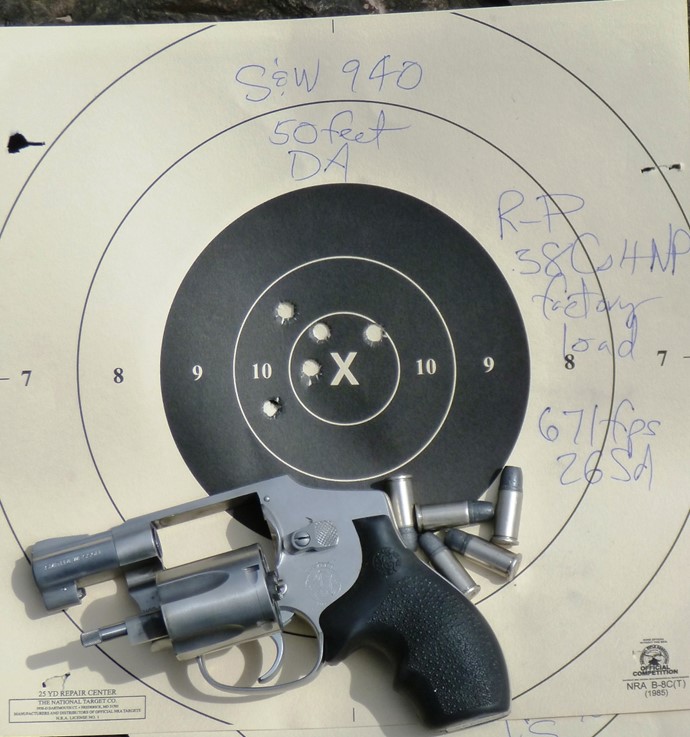

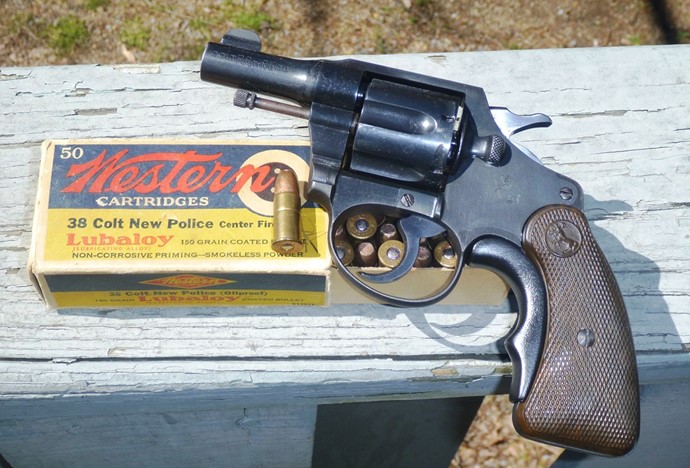

Remington-UMC nickel plated .38 Colt New Police (1940s) gave 671 fps, 26 Sd, 58 ES AND SHOOTS TO THE SIGHTS at 50 feet. The .38 Colt NP round in this gun provides about the same payload and velocity as firing .38 Special wadcutter from a typical 2" snubby. I fired rest of the mixed box of vintage LRN and CNP for function at 25 yards, 6:00 hold, that's exactly where they hit. No malfunctions.

The 940, despite its 0.010" cylinder gap, gives higher velocity with factory 38 S&W ammo than does my S&W Terrier Model 32-1 which has a 0.005" cylinder gap, 671 vs. 614 fps. I attribute this to the 940 building higher chamber pressure by squeezing .360" lead bullets down its .356" diameter cylinder throats, whereas the Terrier has .362" cylinder throats more common of its era.

The pressure build squeezing a fat bullet down tight throats more than compensates for the larger cylinder gap.

That is exactly the same as was experienced with the Ruger India Models. My 4-inch Colt .38 Police Positive has .359" cylinder throats and a .355" barrel groove diameter with 0.005" cylinder gap and produces velocities closer to the Ruger, higher than the 5-inch S&W Victory Model.

73 de KE4SKY In Home Mix We Trust From the Home of Ed's Red in "Almost Heaven" West Virginia

.jpg?width=20)