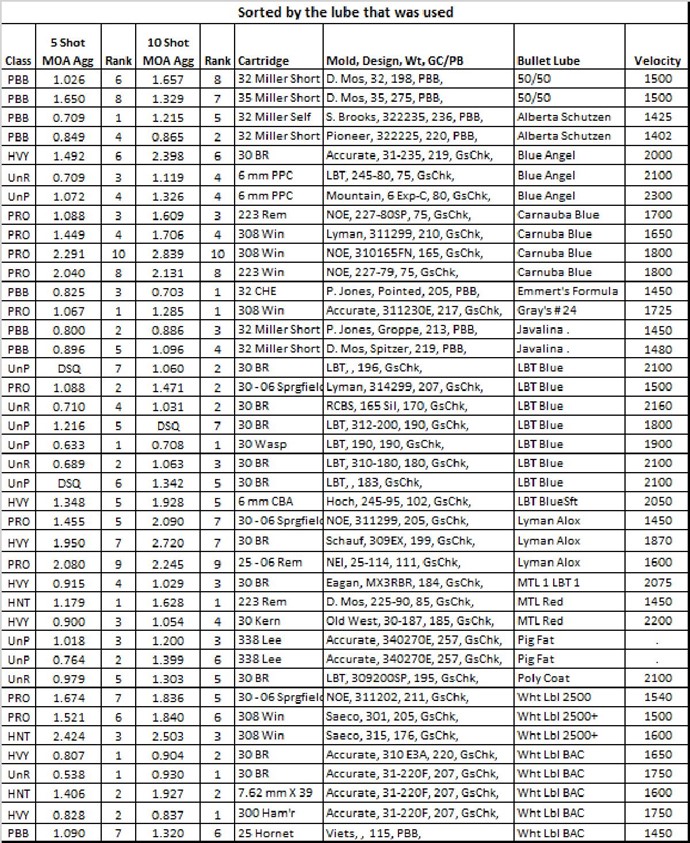

Like most everyone getting into cast accuracy with a long gun I found myself going down the rabbit hole of bullet fit to bore. Believing that there isn't a great chance that I would be able to create a unique design that would set cast bullet accuracy beyond what it is I looked at what other people had created. For reference I stuck with Accurate molds because of the CAD drawings and the flexibility for anyone to tweak existing drawings. Since I'm working with a Production Class .308 I looked at bullets in the 200 to 230gr range.

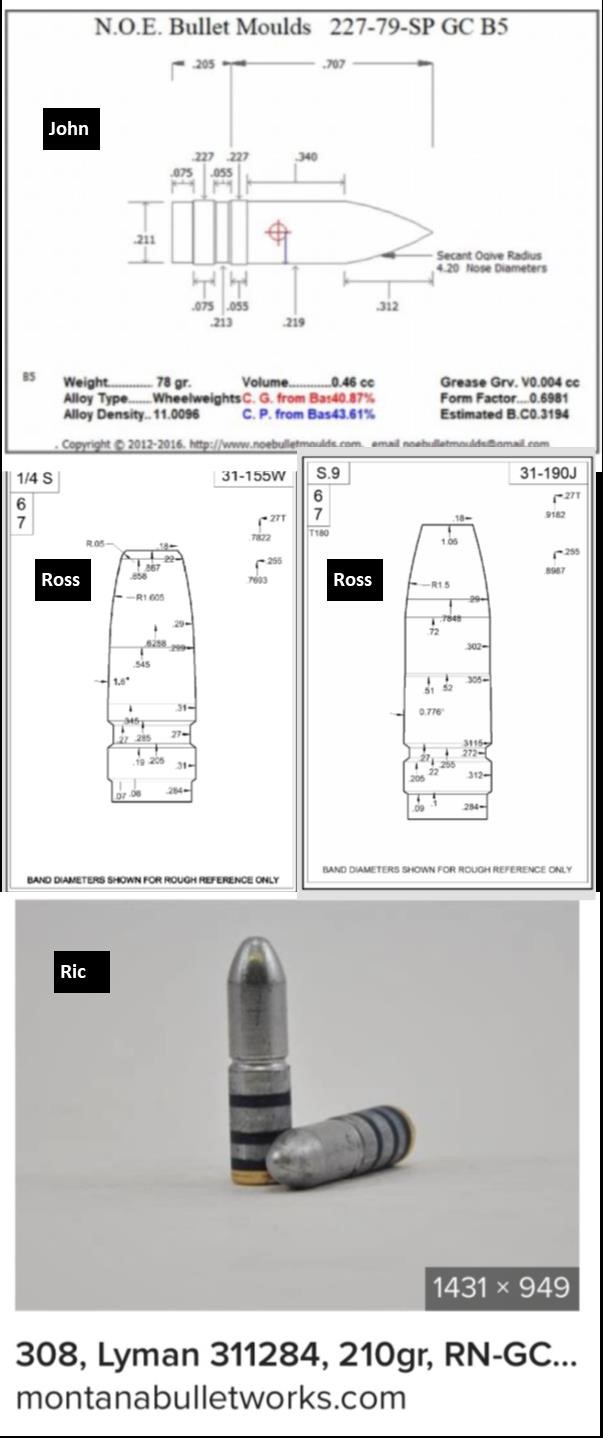

Accurate has 84 bullets listed that would fit in that group. The most popular design is the bore rider which has 55 listings of which 34 are the traditional straight nose design (Sample A), 4 that are of crush design (Sample B), 10 that are hybrid and 7 that I would fit into the "Other" category.

I'm curious if anyone has any history on these designs, possibly the correct name for them (not my "crush", "hybrid", "other"....) and the individual benefits or virtues.

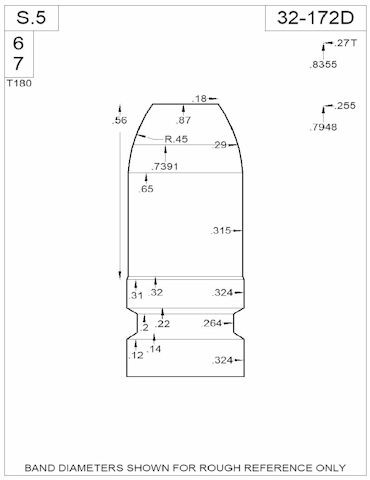

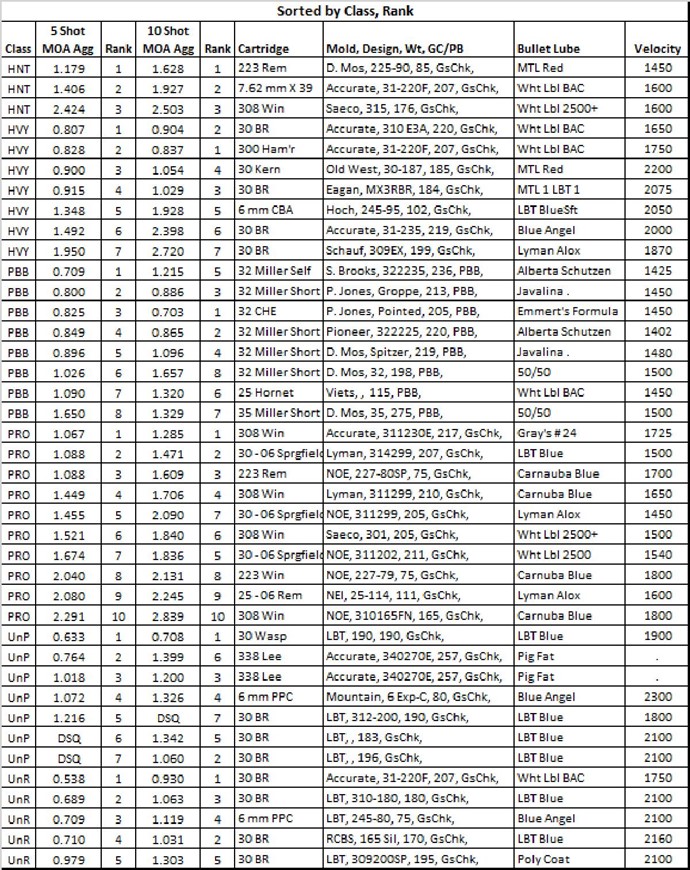

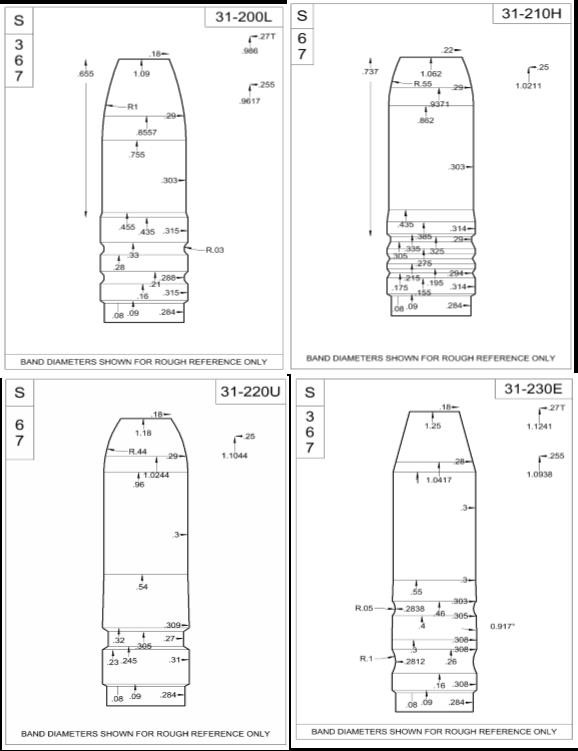

As far as I can see sample A is a straight up bore rider . This is a slight variation of the 311299. Two areas that differ from the Lyman are the .180 flat nose as Accurate produces and the slight bevel from the front driving band to the nose. I think most all of Accurate's designs has this slight bevel where the driving band is given a short ramp into the freebore, lede or the face of the free-bore if you have a tight free-bore. Tapers are as short as .010 but some like Tom's 31.200L are just a little longer. This one has a .020 lead into the straight nose design.

Sample B has a similar transfer of design from the driving band into the straight nose but the taper is longer at over .050". Almost like a ball nose or a spitzer its almost like its designed to crush into the lede as the straight bore rider nose is suported in the lands.

Sample C is what I call a hybrid between a full out tapered nose and a bore-rider. On this one there's a long linear taper from the front driving band to the straight bore-riding nose. In this case the taper runs .135 which looks to me like it would run through the free-bore of most production chambers.

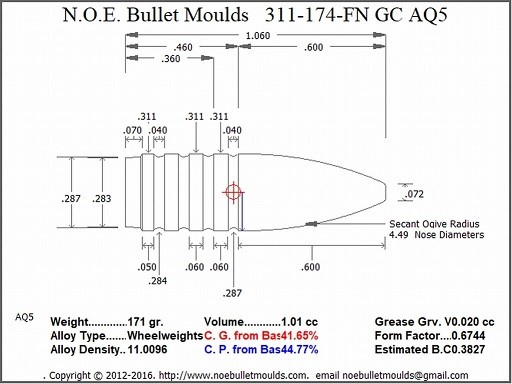

Sample D is confusing to me. The design is very popular because Tom's sold over 40 of them. For the life of me I can't wrap my head around the purpose of the design from .300 to .550 where it then transfers to the bore-rider straight nose design. And that little lube groove between .400 and .460 confuses the heck out of me. Maybe, just maybe this has to do with CP, CG? Probably I'm looking for something that isn't there or just not smart enough to understand its importance.

I can see the benefits of the modified bore-rider designs as it is filling the free-bore area with lead which will give the bullet more traction in the lands. This is my attempt to inch into the subject of variations on the bore-rider design and thus bullet design in general. Thanks, Bill Cook

A “Measured Response” is as effective as tongue lashing a stuck door.