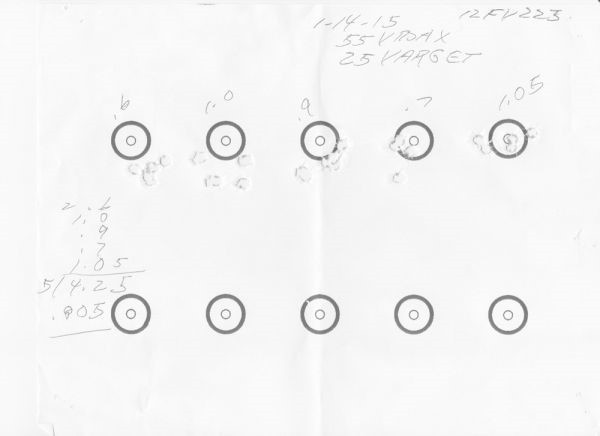

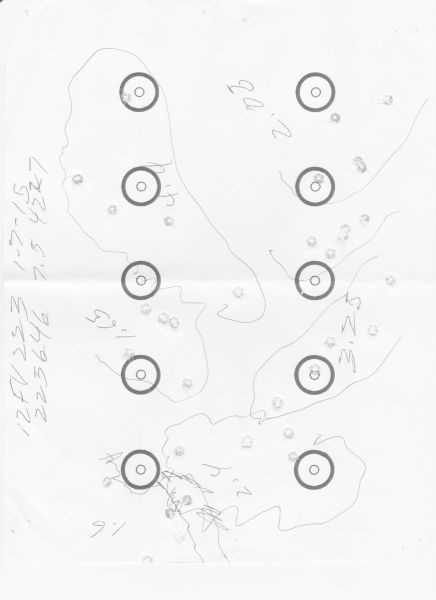

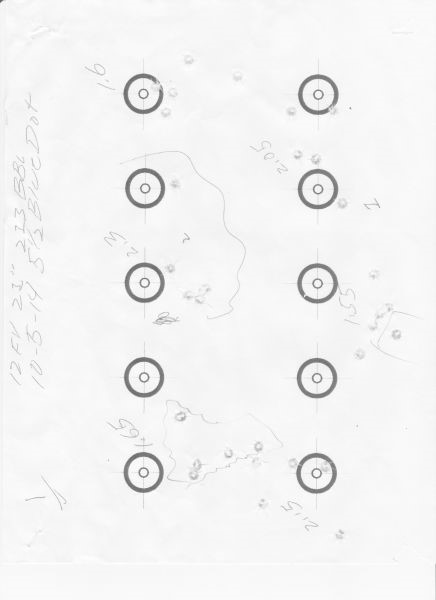

After 2 years, 7 molds, lotsa donated bullets I can't reliably shoot five 5-shot cast bullet groups at 100 yards under 2” average. Including NOE 277-80. This is my second max effort, first started in 2003. I loaded Horn 55 gr VMAX, 25/Varget and shot yesterday. 5 groups 100 yds averaged .85". (pic math wrong) It ain't the gun. Making a 22cf shoot cast is not easy, at least for me. I wonder how the 1” guys do it.

223 UPDATE

- 26K Views

- Last Post 19 January 2016

Attached Files

Joe, Sorry to hear that the NOE bullet didn't improve your luck. How you, and others, can shoot a 311299 in a 308 with your recipe but a near scale model of it won't work in a 223 is strange. I lap or beagle until I get at least four land marks on the nose near the front, use an alloy of 12 - 15 bhn, size .226” for my rifle, give it enough length and neck tension so the bolt is hard to close, try for 1,400 - 1,600fps with a fast, clean burning powder. Sometimes a thin layer of LLA helps for some reason. I suspect that you are already doing all that and more. I can't think of anything else unless it is sporter wt. barrel that doesn't like heavy slow bullets. You might try a shim under the barrel at the forend to change things.

I hope others will join in this discussion. Several shooters are now shooting the 22780 but I don't know how well.

John

Attached Files

Joe, Is that action bedded? You probably have covered this before but just thinking out loud.

Longone

Attached Files

Keep John talking. I'm writing this stuff down.

Attached Files

What type of rifle is it?

I once had some 55gr. jacketed Nosler Ballistic tip bullets that measured an unusually large diameter of.225. These bullets were extremely accurate and shot like a laser beam creating .250” groups very easily. Smaller diameter jacketed bullets of .224-.2243 shot larger groups much like those in picture above. Gun is a factory Remington VS chambered in .223 Remington.

Round bullets, snug fit and shooting skills is key to shooting better groups with cast. “perfection"

Attached Files

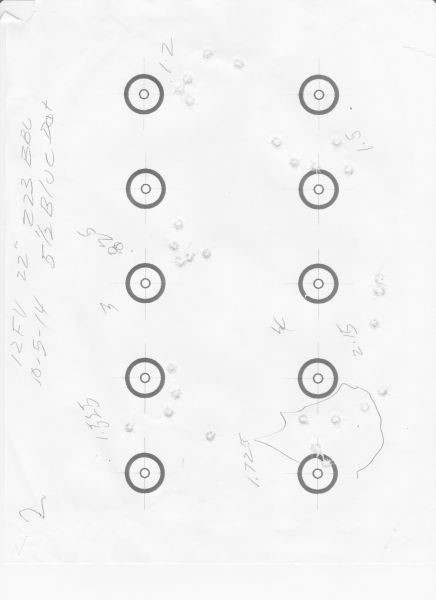

As per John's request I have shot the NOE 80 spritzer some in my custom barreled Savage this is a McGowen 8 inch twist barrel with the Wylde chamber. I tried Bullseye, Red Dot, Green Dot, Unique probably a few others it didn't really start shooting good until I got to the Blue Dot. Six grains of Blue Dot put 10 shots in to .900” at 100 yards but I don't have enough Blue Dot to continue testing I only had about enough to load twenty or so rounds. If some ever shows up around my part of the country I try it some more. As of now that rifle is back on coyote duty with well never mind.

RB

Attached Files

I have also had good luck with 6.0 to 6.7 grains of Bluedot and used it in competition with my 85 grain Mos bullet which is a lot like NOE 80 SP for a couple of years before running out.

John

Attached Files

John,

What twist is your barrel? If the target above is correct the load of 25 grains of Varget is a pretty stout one for a lead bullet I would think. If Joe's FV is a 9” twist it would really be spinning that little bullet.

Longone

Attached Files

Joe's 25 grain Varget load is with a 55 grain Vmax jacketed bullet,not one of his CB loads.

The twist in my rifle is one in eight inches but one in nine will also work with the NOE 80 SP. The eight inch twist shoots 35 and 40 grain Vmax bullets well. I don't think spinning bullets too fast is a problem for most of our shooting -- spinning them too slow obviously doesn't work.

John

Attached Files

Thanks John,

I overlooked that he was shooting jacketed with that target. The reason I asked about bedding was because of the windage groups, it made me wonder in what order they were shot. Usually a side to side group indicates shifting of the action in the stock. All groups except the 4th one displays that shifting.

I do believe that you can over rotate a bullet to the point that accuracy is affected. Obviously the 80 gr. bullet needs the extra twist to stabilize because of the length but the shorter bullets do not need the faster twist. Smaller lighter bullets do well with slower twist as shown by bench rest shooters.

I'm sure Joe has done this but perhaps starting with a load that is at the bare minimum and working up very slowly.

BTW, has he swapped out the scope to verify it's not the problem?

Longone

Attached Files

The greatest examples of over rotation I have seen or heard a bout were: A 22-250 and a 220 swift. Both were shooting light (35- 40) gr bullets at extremely high velocities. The bullets flew apart on the way to the target. I personally think that this is why most of those rifles in those calibers have such slow twists. As compared to the .223. Brodie

B.E.Brickey

Attached Files

What type of rifle is it?

SAVAGE 12 FV VARMINT WEIGHT BARREL

I once had some 55gr. jacketed Nosler Ballistic tip bullets that measured an unusually large diameter of.225. These bullets were extremely accurate and shot like a laser beam creating .250” groups very easily. Smaller diameter jacketed bullets of .224-.2243 shot larger groups much like those in picture above. Gun is a factory Remington VS chambered in .223 Remington.

Round bullets, snug fit and shooting skills is key to shooting better groups with cast. “perfection" I have tried this with the original barrel, 2 223 sporter weight 22” barrels and a heavy varmint 22-250 barrel. None worked = <2” 100 yard 5 shot 5 group averages.

Attached Files

Joe, Is that action bedded? You probably have covered this before but just thinking out loud.

Longone Inspect stock for obvious problems-never found one.Savages are pillar bedded. Put the gun in the stock, pull it back and forth-it should move a few thousandths. Want the recoil lug to hit the stock. Start the stock screws. Pull the action back and screw the REAR screw in while holding bbl and stock, you should feel the bbl move UP. When the screw is sorta tight, front screw, feel bbl and stock. BBL should NOT move up or down as screw tightens. Tighten both screws until farting noise is heard. Bbl-stock dollar bill test. Tang, stock dollar bill test.No Savage stock that fits this way is accuracy-helped by any Devcon or epoxy antics.Savage stocks are ~$30 delivered, see Savage Shooters forum. Many hours and Dremel tools and devcon/plumbers epoxy/epoxy paste etc later and cutting off various stock parts north of the recoil lugs are currently residing in the dump. Marlin Bassett was right, pillar bedding works.

Attached Files

Savage factory stocks with pillars in my experience are all too short to do any good. None I have seen contact metal to metal, and even if they did it would be like setting the action on top of a pile of rocks with no side support.I have attached a pic of my bench rest stock bedding. That stock was built for a Savage Target action, the tang was free floating as was everything in front of and including the barrel nut. The screws were torqued 30 inch lbs. front and center with the rear screw having 5 inch lbs. This rifle was built in 6mm BR and shot .200” 5 shot groups @100 yds. with 68 grain bullets (jacketed). In the bench rest game you don't see fast twist barrels or heavy bullets @ 100 or 200 yards in the winner circle. Savage actions are on the light side of strength so bedding to support them is pretty critical if accuracy is what someone is after, any movement in the stock will change the harmonics and point of impact. Longone

Attached Files

Maybe we are cleaning our barrels too often? Cleaning less may help.

Off to the range I go.

Attached Files

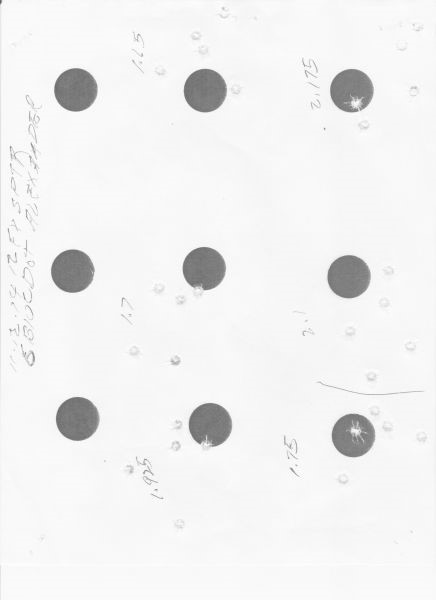

I cut a longer .150" freebore in one off my factory barrels to see if this would help guide the bore riding bullets better. Used 4 different cast bullets (225646, RCBS 55gr, NOE 45gr, Lee Bator 55gr) sized .0001-.0005 smaller than freebore diameter and using same powder charge of 16.5gr 133. All bullets bore ride section had a snug slip fit. Here is my best 10 shot group using the Lyman 225646 lubed with thinned hand dipped Alox. Groups did not improve over factory chamber, but different gun also.

Attached Files

sigh ... your reject group is better than my best lifetime cast group !! ( not counting those mysterious 22 rimfires ) ...

what did your chamber wind up looking like ?? are you getting most of your bullet engraved before firing ?

the questions keep changing faster than we can think up answers ( g ) ...

ken

Attached Files

<user=40>Ken Campbell Iowa wrote: sigh ... your reject group is better than my best lifetime cast group !! ( not counting those mysterious 22 rimfires ) ... what did your chamber wind up looking like ?? are you getting most of your bullet engraved before firing ? the questions keep changing faster than we can think up answers ( g ) ... ken Rifling engraves bore ride section when bullet's front band touches rifling (22 Bator in picture) According to pound cast the free bore now measures .2253” diameter and .150” long. Groove diameter of Remington 1/12 twist barrel is .2245". This barrel is a take off factory barrel that originally had a crooked cut throat. The PTG Throater cleaned up rifling very nicely and evenly. A large .2193 pilot bushing was used on throating tool to help center best. I now full length size my brass for this barrel to counter crooked cut chamber...tight fitting bullet in throat now centers everything before firing. I will eventually cut throat deeper and try longer bearing surface spitzer bullet sized .0001-.0005 under free bore diameter. Hopefully it works? The gun started shooting its best around round 40-50 (see target above)...when barrel was its dirtiest. Hawkeye bore scope shows no leading in barrel. There was a little alox lube star at crown of barrel after test, so lube is plenty...I think. I will not clean this barrel and test again. Seems that Lyman Moly lube did a little better in grouping department about 3 weeks ago, but in a different rifle.

Attached Files

Savage factory stocks with pillars in my experience are all too short to do any good. None I have seen contact metal to metal, and even if they did it would be like setting the action on top of a pile of rocks with no side support.I have attached a pic of my bench rest stock bedding. That stock was built for a Savage Target action, the tang was free floating as was everything in front of and including the barrel nut. The screws were torqued 30 inch lbs. front and center with the rear screw having 5 inch lbs. This rifle was built in 6mm BR and shot .200” 5 shot groups @100 yds. with 68 grain bullets (jacketed). In the bench rest game you don't see fast twist barrels or heavy bullets @ 100 or 200 yards in the winner circle.

Savage actions are on the light side of strength so bedding to support them is pretty critical if accuracy is what someone is after, any movement in the stock will change the harmonics and point of impact.

Longone

So, tell us how much the bedding reduced group size.

Attached Files

I cut a longer .150" freebore in one off my factory barrels to see if this would help guide the bore riding bullets better. Used 4 different cast bullets (225646, RCBS 55gr, NOE 45gr, Lee Bator 55gr) sized .0001-.0005 smaller than freebore diameter and using same powder charge of 16.5gr 133. All bullets bore ride section had a snug slip fit. Here is my best 10 shot group using the Lyman 225646 lubed with thinned hand dipped Alox.

Groups did not improve over factory chamber, but different gun also. Is this about a 2 3/4” 10 shot 100 yard group?If so, it's kinda like what I'm shooting.My groups are enlarged with flyers that make the average BIG!

Attached Files

My best 10 shot groups in .223 are also with the 225646 checked and tumble lubed. My rifle is an NEF Ultra Varmint with the older 1:12 twist and will do just under 1” @100 yards. JoeB has tried this bullet and written it off as not terrific in his rifle. I don't think it is just our particular rifles that like this terrific bullet. I think it is a great bullet with a nice short nose and a long bearing area that casts large and is sizable correctly for many rifles. Mine finish at 59 grains all up in #2 alloy with an Aluminum check and 45:45:10 tumble lube.

I lucked into a sale on that mold years ago and haven't looked back. It shoots for me.

Gary

Attached Files

Joe, I've been trying to think what could be keeping you from better groups.

If the bedding is .85 moa OK with jacketed it is hard to imagine that is isn't OK with the much milder CBs.

As Ken has pointed on occasion, if you and your scope, bench, rests, and technique can produce .85” JB groups looking at those things isn't likely to be profitable.

It is conceivable that a barrel with a particular kind of defect would still shoot well with JB but the defect would affect CB accuracy. I have a theory about that but no evidence and have never heard anybody else claim such.

The only thing that comes to mind as a possibility are bullets distorted during seating. Have you pulled a bullet to see if is still same size and shape as before seating?

John

Attached Files

Joe B.

Have you ever checked that barrel for a tight spot somewhere along its length. I small one that did not affect jacketed bullet accuracy could certainly effect cast bullet accuracy.

Brodie

B.E.Brickey

Attached Files

If those are 1” squares, it looks like a 1 7/8 group with 9 shots in 1 3/8

Frank

Attached Files

I have another Remington with 20” bull barrel and good factory chamber throat that shot under 1” @ 100 yards using the 225646 (beagled larger diameter). Seems all my 223 rifles shoot best when barrel is dirty. It can take as many as 40 rounds fired before both guns start grouping well...probably the alox lube. I will try different lube next time.

Attached Files

Joe B.

Yes, with a cleaning rod and tight patch. Because a couple of years back I found a ??carbon ring?? in a barrel, cleaned it out, and accuracy came back.Can't feel anything in the Varmint weight 223 or 22” light sporter. Note that I've (let me check) tried 5, (thought it was 4) barrels. 4 in 223, 1 in 22-250.

Have you ever checked that barrel for a tight spot somewhere along its length. I small one that did not affect jacketed bullet accuracy could certainly effect cast bullet accuracy.

Brodie

Attached Files

Joe,

I've been trying to think what could be keeping you from better groups.

If the bedding is .85 moa OK with jacketed it is hard to imagine that is isn't OK with the much milder CBs.

As Ken has pointed on occasion, if you and your scope, bench, rests, and technique can produce .85” JB groups looking at those things isn't likely to be profitable.

It is conceivable that a barrel with a particular kind of defect would still shoot well with JB but the defect would affect CB accuracy. I have a theory about that but no evidence and have never heard anybody else claim such.

The only thing that comes to mind as a possibility are bullets distorted during seating. Have you pulled a bullet to see if is still same size and shape as before seating? No. My bullets are pretty hard, they seat pretty easily except for a stranger now and then. I'm crimping now, trying to keep them from changing oal , if they do, or did, during seating. It's the flyers that do me wrong. John

Attached Files

Joe B.

I was think of a similar thing to Brodie when I made the remark above only maybe a loose spot.

Have you ever checked that barrel for a tight spot somewhere along its length. I small one that did not affect jacketed bullet accuracy could certainly effect cast bullet accuracy.

Brodie

I have had four Savage varmint wt. rifles in the last 15 year. All averaged 5 shot groups with JB between .7 and .8moa but never shot CBs as well as I thought they should. All four had a very loose bore for a foot or more in the middle. A lead slug upset ahead of the throat would almost free fall in the loose area and then tighten up again in the last few inches at the muzzle.

Theory: JB's are elastic and spring back and don't mind a little gas leakage. CBs aren't elastic don't spring back and do mind gas leakage (I got hard black fouling in the loose areas with some powders.) Don't know if there is anything to this theory or not but when I bought a fifth Savage and immediately slugged it there was the same loose area. The dealer took it back -- rare dealer.

I don't know what Savage is doing to consistently produce a loose spot in their 22 barrels but I have had five straight examples.

John

Attached Files

I'm with John, either a tight or a loose spot will degrade accuracy with cast projectiles. Brodie

B.E.Brickey

Attached Files

Here's the deal.I can't make a 223 shoot cast bullets. John Alexander can, after spending many years and the GNP of Gambia on equipment.Others mumble about one inch groups. How about we open this thing up, and you successful 22 CF shooters show us some 5 shot 5 group 100 yard targets. With measured group sizes.

I think I just moved to Missouri.

Attached Files

it would not be a good time for me to repeat my thought that you production guys are really just testing rifles,

so i will not do that.

maybe what we need is a new class ...

” modified production ” rifles ... can joe rechamber a savage barrel and find success ? what would happen if you screw a tikka/sako barrel on a savage action ...

is it joe or is it savage-wrecks ?

i see great cba results by 30 cal savage ... has anybody got a savage rifle in 22 to shoot 1 moa ? maybe savage can not make quality 22 barrels ? jeeze, h&r handi rifles are beating them !!

there is some value in joe's experiments .... when testing ... failure to improve results means you can eliminate that approach as the right thing to do ... ( g ) ...

ken

Attached Files

it would not be a good time for me to repeat my thought that you production guys are really just testing rifles,

so i will not do that.

maybe what we need is a new class ...

” modified production ” rifles ... can joe rechamber a savage barrel and find success ? what would happen if you screw a tikka/sako barrel on a savage action ...

is it joe or is it savage-wrecks ?

i see great cba results by 30 cal savage ... has anybody got a savage rifle in 22 to shoot 1 moa ? maybe savage can not make quality 22 barrels ? jeeze, h&r handi rifles are beating them !!

there is some value in joe's experiments .... when testing ... failure to improve results means you can eliminate that approach as the right thing to do ... ( g ) ...

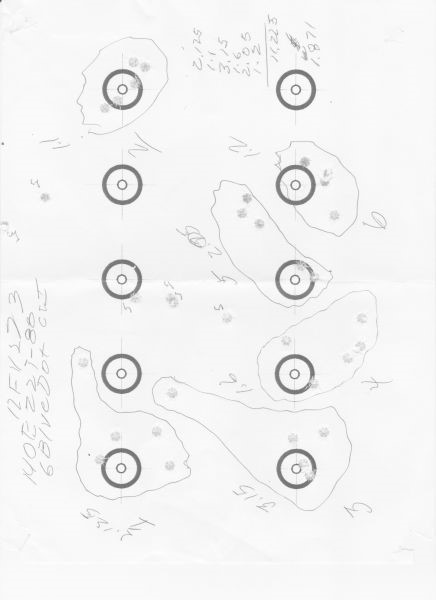

kenFrom 2001 to 2014 there were 162 PRO entries at the CBA NM. Of these, 86 = 53% were Savage rifles. Next was Rem, 43, 27%.I doubt that Savage makes 22 barrels that shoot jacketed but not cast. They seem to make barrels that shoot jacketed in all calibers accurately. And 30 cal that shoot cast accurately.My error was, perhaps, in believing that it is reasonably easy to find 22 CB accuracy at 100 yards without evidence that others, other than John, had done so.Maybe everybody's shooting big 22 CB groups, and talking about the wallet groups. On a more technical note, on the NOE 227-80. The bullet won't go in the gun unless almost all the base in below the neck. Crimping so that the top band is out of the case sorta allows the ctg to go in with a hearty push. The GC shank and GC don't match well, it takes fiddling/expanding to get the check started on the shank straight, and force to seat the GC. Seating GCs is a separate step, has to be for me. Seating GCs force expands noses .0003"-.001", magnifying the chambering effort. Lee sizing dies don't seat GCs correctly, 22 or 30, for me. However, Lee sizing reduces the bumping when sizing, so use it. Both 22 and 30. The process is: Inspect, seat GC, lube in the 450 in a .228” die, size in Lee .226” die.For some reason LBT, NOE and NEI all make GC shanks too big for Horn. GCs-GCs will go on, but fiddling is required. Lyman knows the secret dimension.The accuracy problem may be that the bullet nose is too big. This is common problem with 415, 646, LBT etc. So, it's the gun's problem. So, I'm shooting jacketed to try to get a barrel leade opened up a bit. Either shooting CF 22 cast accurately is very difficult, or I've found a set of barrels and equipment that's uniquely bad. Let's see those targets with 5, 5 shot 100 yard measured groups. BTW, soft bullets should work, but bump WAY up in GC install. No help.

Attached Files

show us some 5 shot 5 group 100 yard targets. With measured group sizes.

I think I just moved to Missouri. I too wish more posters on this forum would specify more exactly what they are getting for groups. Nothing wrong with showing a single group but it tells us very little about what the rifle and load will shoot. We all already know that. It is barely better than the common “it shoots very well” or “will do one inch when I do my part” Twenty to 30 shots on the same piece of paper would be a big advance in communication.

It could be one 25 shot group, five 5-shot groups, three tens, ten threes -- fliers and all.

Even some of the popular gun rags (Shooting Times and Rifle Shooter) have begun to come closer to the long time Am. Rifleman standard of using the average of five 5-shot groups.Sometimes it is only five 3-shot groups but that is world's better than quoting or showing one group or quoting the best group as some still do.

John

Attached Files

From 2001 to 2014 there were 162 PRO entries at the CBA NM. Of these, 86 = 53% were Savage rifles. Next was Rem, 43, 27%.I doubt that Savage makes 22 barrels that shoot jacketed but not cast. They seem to make barrels that shoot jacketed in all calibers accurately. And 30 cal that shoot cast accurately.My error was, perhaps, in believing that it is reasonably easy to find 22 CB accuracy at 100 yards without evidence that others, other than John, had done so.Maybe everybody's shooting big 22 CB groups, and talking about the wallet groups.

On a more technical note, on the NOE 227-80. The bullet won't go in the gun unless almost all the base in below the neck. Crimping so that the top band is out of the case sorta allows the ctg to go in with a hearty push. The GC shank and GC don't match well, it takes fiddling/expanding to get the check started on the shank straight, and force to seat the GC. Seating GCs is a separate step, has to be for me. Seating GCs force expands noses .0003"-.001", magnifying the chambering effort. Lee sizing dies don't seat GCs correctly, 22 or 30, for me. However, Lee sizing reduces the bumping when sizing, so use it. Both 22 and 30. The process is: Inspect, seat GC, lube in the 450 in a .228” die, size in Lee .226” die.For some reason LBT, NOE and NEI all make GC shanks too big for Horn. GCs-GCs will go on, but fiddling is required. Lyman knows the secret dimension.The accuracy problem may be that the bullet nose is too big. This is common problem with 415, 646, LBT etc. So, it's the gun's problem. So, I'm shooting jacketed to try to get a barrel leade opened up a bit.

Either shooting CF 22 cast accurately is very difficult, or I've found a set of barrels and equipment that's uniquely bad.

Let's see those targets with 5, 5 shot 100 yard measured groups.

BTW, soft bullets should work, but bump WAY up in GC install. No help.

Joe,

Thanks for the details. If the nose of the NOE 80 (or a 311299) won't go up into the bore and either touch or come very close to touching the lands you no longer have a bore riding nose bullet but a blob of lead shaped like a bullet whose size and shape make no sense for that rifle. I am surprised it shoots close to 2".

I doubt that it's that easy, but it sounds to me like you have a batch of undersized gas checks if they won't snap on with finger pressure on bullets from several different molds. I think you know that the gas check problem is at the seat of your trouble. if you can put on gas checks with finger pressure (without expanding the checks first) the Lee die should seat them fine. This problem isn't new. At one time Hornady was making gas checks that would only fit on about half of my collection of 22 molds -- better for the last ten years. What is the diameter of the GC shank on your bullets? Maybe it is out of spec. Does anybody have any 22 gas checks on the large size to send Joe a few. Are gators or ?? likely to run larger? Will aluminum ones go on easier? I don't know what's on the market. Do some run large? I will look at my assortment and send the biggest.

To get more information. Forget the gas check and size a couple of bullets in the .226” Lee push through. (Do a few in a .225” Lee as well if you have one to cover the bases.) Will they fit with the nose in the bore and forward motion stopped when the front band hits the taper? If so, when pushed back out. Are there land marks on the nose? How many and how long? If the nose won't go all the way into the bore try a softer bullet (ww or softer) and repeat. If the nose of the softer bullet won't go fully into the bore then the nose is simply too big for your bore. One has to change.

When the bullet goes in and fits like it is supposed to the NOE 80 will shoot. There is no black magic keeping a 22 from shooting cast -- just reasons. Don't give up.

John

Attached Files

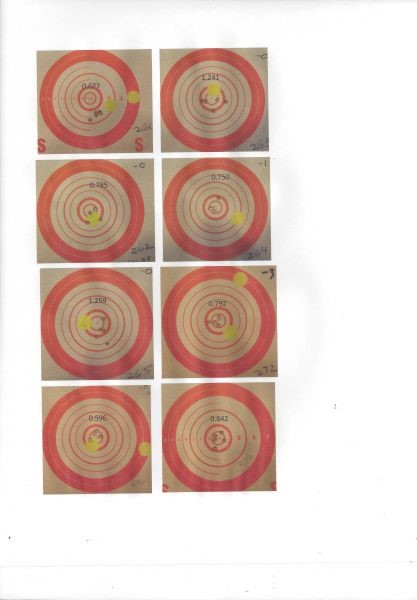

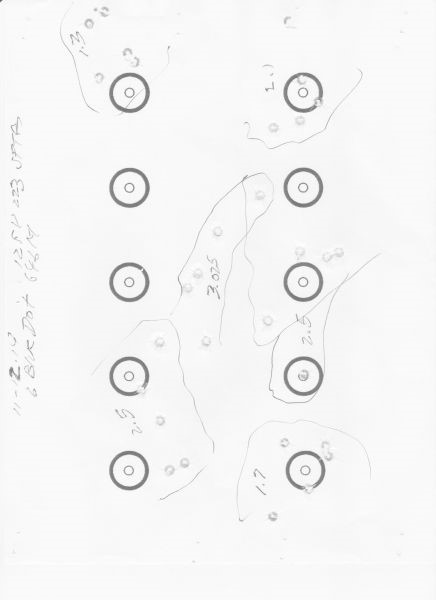

I have posted my group sizes before. The good, bad and ugly. Quite a few were test loads which exceeded alloy strength, but they were included anyway. I looked back through my records to one day where I didn't try to break the land speed record. December 30, 2007, shot 20, 5-shot groups. Alloy was 78-7-18, LBT lube, some at GC only, some at GC+1 groove. Bullet was RCBS 22-55-SP, Hornady GC. Powder was IMR 3031 from 17.6 grains to 21.2 grains. Velocity ranged from 2051 to 2672 fps. WSR primers. Cast weight of the bullet was 51.5 grains. These bullets cast just barely .2245; they were run through a .225 push through die with GC and lubed in a .226 RCBS die. Rifle is a Remington with a Shilen barrel. Here's the bad part: it has one of those horrible 1:14” twist barrels which will not be competitive with cast. These photos were in a different format and may be hard to see. The twenty group average for this day was 1.153. Largest was 3.046, smallest was 0.516. I'm curious where Joe's 5, 5-shot group photos with measurements are.

Attached Files

This has a pdf attached. Maybe it will be easier to see.

Attached Files

thanks paul ... dang ! this 22 accuracy thing is worse than following hansel und gretel through a woods full of hungry crows ...

ken

Attached Files

Excellent, consistant accuracy, Paul.

What does the GC+1 mean?

Frank

Attached Files

Lube at GC is lube only at the gas check groove. GC+1 is lube at gas check groove plus the lube groove. The RCBS bullet only has one lube groove.

Attached Files

geeeze joe ... you convinced me !! those are ALL fliers !!!

re: gas checks ... try shooting the gas checks backwards ... doesn't seem to bother my 3 inch groups any . watch for a gas check stuck in barrel... i have never had one do that, never heard of that, and other cast shooters have tried that. seems dumb, but while we are scratching heads, might as well add a few more data points.

i have all kinds of 223 and 224 throater reamers, and would be glad to throat your barrel, but i am retired as a gunsmith and can't work on other's guns, legal wise. makes us all safer; national security, ya know.

also, you would be ill-eagle in some cba classes, if that matters.

ken

Attached Files

Finally!

7 sheets of targets x 6 per sheet. 42 groups. If I can read it right, that's a 1.966 Agg for the whole bunch. At first glance, it looks kind of bad. Go look at the Postal Match results for Match #12 Little Bore for the past several years. Other than John Alexander with his relentless pursuit of the .22, not many are doing that well with a small caliber production rifle. You can probably take 2d place most of the time.

My .222 barrel is not a production rifle. It took lots of fitting to get it right, and I'm still not sure it's right.

Attached Files

The dispersion patterns on your target show several directions and a lack of centering. The patterns indicate more than load or rifle deficiencies. Variance this broad indicates something to me that I don't think you really want to hear, but, somebody should have told you a long time ago. You don't try hard enough and you pull the trigger when you are not aiming and holding correctly. This does not look like serious shooting to me. The dispersion is not regular enough to blame the rifle or load. You, the shooter are at fault.

Your statistical studies will not come to the same conclusion I am giving you. I am unaware of any statistical method that plots trends in the directions of hit patterns. Group sizes and distance from point of aim programs will not indicate what I am concluding. Your dispersion is in a wide variety of directions and the results indicate poor shooting more than anything else to me.

Respectfully,

Gary

Attached Files

Gary,

Joe has already reported that when shooting jacketed bullets in the same rifles he averages .85". To be unable to shoot the much less powerful CB loads with practically no recoil, or twist and a less obnoxious report would be pretty strange.

I am always very skeptical when anybody examines somebody else's groups and draws conclusions about what is, or isn't, happening without knowing more about the local situation and conditions. There is usually way to many random things happening to be sure what you are seeing. I believe we should exercise a lot of humility when trying to “read' somebody else's group and give advice -- much less criticism.

Also we should be very cautious when tempted to tell others what they do, or don't, want to hear and how hard they are, or are not, trying to do better. Please try to imagine yourself on the receiving end of such an analysis of your lack of open mindedness, and your lack of trying.

Respectfully,

John

Attached Files

Gary choose not to take my gently offered advice about considering humility as a virtue useful on the forum and doubled down on his criticism in a way that I judged off base and unhelpful to discussion on this thread. I removed his message and will remove any future messages from anyone using a tone that seems more likely to stop discussion than to further it. We often have different opinions and should feel free to express them and support them with evidence on the forum, but they must be expressed in a civil way and cannot disparage and belittle other posters.

Thanks for your cooperation.

John

Attached Files

John, I saved my post offline before you deleted it , if you choose reconsider, let me know.

Gary

Attached Files

I'm still looking forward to seeing targets with 5 groups, 5 shots 100 yards 22CF.

Attached Files

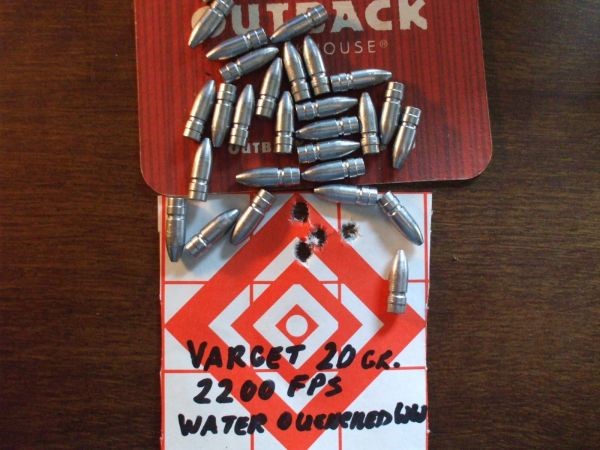

Soon I will be trying a custom LBT bullet that has a .225 sized bearing surface from ogive to base. Throat had to be cut deeper for this to hopefully work. Bullet is .710 long, bearing surface length .400 and weighs 62 grains cast with Wheel Weight alloy and 59 grains cast with linotype. Bullet has a snug slip fit into .2251” diameter leade. My Remington has a 1-12 twist barrel. Veral does excellent work and believes higher velocities work best...the harder the alloy the better. First I will try hard Linotype and Water Quenched Wheel Weights. Later I will try slower velocity and softer alloy. Standard Hornaday gas checks fit easily BTW. The long seated bullet in picture also fits magazine well. Zero bullet wobble in flight is the trick for great accuracy.

Attached Files

I just ordered a Lee collet crimping die. Maybe that's a secret.

Attached Files

for several years for new to me catriges ...i order a lee collet sizer, a hornady floating seater, and a lee factory crimp die.

on the other hand, after 30 years of job shopping, we often got in screwed up work to fix ... i can testify that it is far better to make something correct in the first place than try to fix it later.

ken

Attached Files

I like the Forster die set. For my crooked factory chamber I full length resize and set the shoulder back .002 using my Forster full sizing die. Oversize expander buttons are available in sizes .224, .2245, .225.

When seating the bullet I use the Forster inline seater. I opened it up from .2245 to .225 to accept larger cast bullets.

Attached Files

I cut the throat a tad too deep.....which may be a good thing. Bullet fit is really snug slip fit in free bore...much like a fat nose bore rider when chambering. I will let you guys know how well this works.

Attached Files

Crimp?

Yes, it's the new thing. All the best people are crimping. You're not? Tsk.

Attached Files

I have posted my group sizes before. The good, bad and ugly. Quite a few were test loads which exceeded alloy strength, but they were included anyway. I looked back through my records to one day where I didn't try to break the land speed record. December 30, 2007, shot 20, 5-shot groups. Alloy was 78-7-18, LBT lube, some at GC only, some at GC+1 groove. Bullet was RCBS 22-55-SP, Hornady GC. Powder was IMR 3031 from 17.6 grains to 21.2 grains. Velocity ranged from 2051 to 2672 fps. WSR primers. Cast weight of the bullet was 51.5 grains. These bullets cast just barely .2245; they were run through a .225 push through die with GC and lubed in a .226 RCBS die. Rifle is a Remington with a Shilen barrel. Here's the bad part: it has one of those horrible 1:14” twist barrels which will not be competitive with cast. These photos were in a different format and may be hard to see.

The twenty group average for this day was 1.153. Largest was 3.046, smallest was 0.516.

I'm curious where Joe's 5, 5-shot group photos with measurements are.

Well Paul, you're shooting WAY faster than I've tried, following John's lead.No other groups have shown up, although there's all the advice and comment one could desire.I've had another 2 weeks of shooting with no different results, no matter how careful I am.I'm beginning to suspect that the tales of mind velocity 22 cf groups are just that, tales; spun by non-shooting advisors who like to see their tales on the screen.Taking Dave Marantz's advice, I'm putting the 22 cf guns, barrels mol;ds et aside for a while. But, I've kinda decided 22cf accuracy is thin on the ground.

Attached Files

Joe B wrote:

From 2001 to 2014 there were 162 PRO entries at the CBA NM. Of these, 86 = 53% were Savage rifles. Next was Rem, 43, 27%.I doubt that Savage makes 22 barrels that shoot jacketed but not cast. They seem to make barrels that shoot jacketed in all calibers accurately. And 30 cal that shoot cast accurately.My error was, perhaps, in believing that it is reasonably easy to find 22 CB accuracy at 100 yards without evidence that others, other than John, had done so.Maybe everybody's shooting big 22 CB groups, and talking about the wallet groups.

Reading and research sometimes does not tell the whole story.

There was a question how Savage could make all good .30 caliber barrels, but not .22 barrels. By reading about match results in the Fouling Shot, Savage rifles were used extensively in production class. Those good shooting rifles may not all have been good. You don't get to see the poor shooting ones; theyhave been tested and discarded. My son and I both got Savage Model 12, .308 Winchesters which shot well out of the box. Two people at Washtenaw had the same model rifles which would not shoot cast, and they tried lots of things. One person sold the rifle, the other one swapped out two more barrels before finding a keeper. Julian Cottrell went up to the Savage factory to complain about one of his Savage rifles which would not shoot cast. He knew how to shoot cast. My son got another Savage .308 Win which looked like it would really shoot, Accutrigger and all. It would not. It now has an accurate (with cast) Shilen barrel on it.

Maybe you haven't found a good .22 caliber barrel yet. I haven't messed around with a Savage 22 barrel, so don't know anything about them. By the way, you stated that you wanted consistent 5, 5 shot groups to be less than 2 inches. My math says you are already there; or did you really want one inch?

Attached Files

HMMM ...does this mean ... in the framework of our current american progressive code of fairness ... that we should all chip in 20 cents each and buy john a. one count new box stock production savage 223 ?

just sayin'

ken

ok, according to cba results PRODUCTION rifles seem to shoot 1.8 to 3 moa ... but then so do production 30 calibers ... maybe we have learned how well production rifles shoot, and that class is about wind doping, casting skills, and .. ok ... luck in getting a good rifle.

i really don't mean to poke fun at production rifles, it is just that my curiosity is in how to make them shoot cast better ... and then they become modified something or others ...and i doubt that there are very many cast shooters who would be interested in a ” modified stock ” class ... maybe production sporter with original sporter barrel but otherwise free modifications ...

Attached Files

I have a second hand Savage 30-06 barrel, 22” light sporter, I've never put it on an action.. I am absolutely confident that I can screw it on a M10 or M12 action and shoot < 2” first time out. I am so confident, that I'd wager big money on it. BIG money! if 5 22cf barrels won't work, I'm not going to search for a 6th in hopes it will shoot. Repetitive failure is, or should be, a teacher. See the steam car, coal fired airplane, hydraulic computer and lazer bathtub.

Attached Files

Theory Only: Regarding Alliant Blue Dot. The software Quickload suggests about 6 grains of Alliant 2400 to produce a pressure/velocity graph very similar to that generated by Blue Dot..Might this be a lead to finding a dupliate for Blue Dot. Loren

Attached Files

I have had four Savage varmint wt. rifles in the last 15 year. All averaged 5 shot groups with JB between .7 and .8moa but never shot CBs as well as I thought they should. All four had a very loose bore for a foot or more in the middle. A lead slug upset ahead of the throat would almost free fall in the loose area and then tighten up again in the last few inches at the muzzle.

I don't know what Savage is doing to consistently produce a loose spot in their 22 barrels but I have had five straight examples.

John

Were the guns like this when in new condition? I wonder if your reduced cast loads caused detonation and were cause of the loose spots.

Attached Files

Has anyone ever tried Trail Boss powder in the 223? This powder fills the case well. I plan on trying it with lower velocity 1100-1600fps and WW alloy. I also have some bulky Tin Star powder I would like to try.

Attached Files

Were the guns like this when in new condition? I wonder if your reduced cast loads caused detonation and were cause of the loose spots.

When I buy a rifle that I plan to shoot cast in the first thing I do is slug the throat area then a half inch ahead of the throat, then at the muzzle, then expand a slug one half inch ahead of the throat and push it through the bore to the muzzle. This doesn't take long and I like to know what it it I am working with or shouldn't be wasting my time with. All four of the Savages were new then i did this slugging and measuring.

The loose places in the middle of the barrels are nothing like the short bulges caused by wads, bore obstructions, etc. The whole central third or more of the bore would offer practically no resistance to the forward motion of the slug and then each of the four tightened up again an inch or two from the muzzle. Groove diameter ahead of the throat and at the muzzle were nearly identical. I could saw one of the barrels in two in the middle and find our that the groove diameter is in the middle but haven't gotten that curious yet.

I have no idea what Savage is doing to cause the loose area for over a dozen years and don't know if other caliber Savage barrels have such a defect.

I don't think it unreasonable to speculate that JB (elastic) might shoot well which they do but CBs (inelastic and incapable of springing back) might not do so well. I do get hard black fouling in the loose areas with some powders -- blowby??

John

Attached Files

<user=8191>OU812 wrote: I cut the throat a tad too deep.....which may be a good thing. Bullet fit is really snug slip fit in free bore...much like a fat nose bore rider when chambering. I will let you guys know how well this works. I tried several different loads and groups sizes were from 3/4” to 3". Larger groups were caused by powder column shift with reduced lower velocity loads. Here is my best group using 20grs Varget. First shot was high so I corrected and shot this 4 shot group. Lower velocity soft WW loads: 2400 7grs was accurate, but very sensitive to powder column shift. I had to raise gun between shots to get best accuracy (shift caused 1000-1500fps velocity spread). 1680 10grs was same, but also accurate @ 1675fps. Trail Boss 7grs was verygood @ 1400fps and close velocity spread without lifting gun between shots. Higher velocity water quenched WW loads: VV140 22grs did very well @ 2577fps. Best load was 20grs of Varget @2200fps. I will load more of best loads and shoot 10 shot groups just to see how consistant accuracy is. Why is Veral the only person that can cut a custom mould on the fly? I requested this bullet and received it in less than 5 working days.

Attached Files

Tools used. Cutter actually measure .2240, but will cut slightly larger @.2243. I lapped throat area with bronze brush and 320 lapping compound to increase to .3245 and to smooth area. I also polished using Flitz polish and bore snake.

Attached Files

"Bullet fit is really snug slip fit in free bore"

I have complete support for that kind of bullet fit resulting in what you are getting on paper. That snug slip fit in the free bore is exactly what my goal is for bullet fit and I get similar results with that kind of bullet fit, every time I couple that with bullet alloy selected to match the ballistic pressure of the load. I also polish my bores for all my cast bullet rifles.

Gary

Attached Files

My ultimate goal is good “CONSISTANT” grouping @ 200 yards (not just one good group so often seen in this forum). Higher velocity and a bullet with low drag will help. This bullet weighs 62grs and shot from 1/12 twist factory Remington barrel.

Attached Files

Way back in the mid-1950's, I had a box-stock M-70. SS barrel and all. Got a wild hair, and sent to Reinhardt-Fajen for a Beavertail fore-end target type stock, which I finished/inletted. Shot very well indeed, particularly for a stock, sporter-weight barrel.

Started messing with cast bullets; had such a tough time that sheer cussedness was the only thing that kept me going for the accuracy rainbow.

Finally, after about a thousand rounds, somehow I hit on something that not only worked, but worked unbelievably well.

Lyman 225415 with Sierra gas checks and 10.1 Gr. of SR 4759. Not 10 gr, not 10.2 gr, but 10.1 gr. was the magic number. Stock, out-of-the-box Lyman lube. Can't begin to tell you how I came to it, only that it was a long road. But, those sub-moa groups just kept pouring out of that thing, and it just had to be dumb luck. Only thing out of the ordinary was that I weighed the powder to get exactly 10.1 grs.

I hesitated to relate this story; I didn't want to sound like somebody on that “other” list.

Don't know if it means anything, except that I'd love to start all over again, returning to age 23 and see if I could do it again!

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

billglaze ...wonder what catridge wuz that m70 chambered for hope it was 220 swift !! that would be interesting !!

sierra gas checks ... were those crimp-ons ?

ken

Attached Files

Yep, 220 Swift. Sierra gas checks were exactly like the old Lyman--slip fit. This was all before I had even heard of LBT and hardening lead. Stock wheel weights. Didn't know nothin'. I even melted some Zamac from the factory where I worked; seemed to me that I could use it to make bullets. Which I did. I only remember that, casting with a ladle, I had a terrible time getting the mold to fill out, and the resulting bullets weighed on the order of 36 gr. as opposed to the same weight in lead being about 52-55 gr. Resulting accuracy was somewhere between bad and terrible. B TW: Inasmuch as it was impossible to blue SS, Winchester iron-plated the barrel, and then blued the plating. Worked great, and had a surface finish that appeared very lightly sandblasted. Attractive. Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

Did testing with softer WW alloy and SPG lube. Tin Star powder did best...cold barrel fliers are a problem . 2400 did well, but powder column shifting cause vertical spread... first 2 shots high. I wonder if Powder Coating will prevent lube related flyers

Attached Files

Trying different lubes and powders in my Remington VS. These groups were shot using Lyman Moly lube, Vectan AO flake powder and Custom 62 grain LBT bullet. The Vectan AO powder has a higher bulk density than Unique and meters very easily without hang ups in measurer. Just guessing velocity ranged from 1400 to 1900fps. Started showing signs of high pressure at 9.0 grains (flat and cratered Winchester primers). I am closing in on consistant grouping and next try will be for score. I am still learning the Weaver 36 power scope tracking adjustment.

Attached Files

i am impressed . especially your earlier use of trail boss ...that might work well in a 6 br... or 22 br ...

ken

Attached Files

All groups shot using a bipod. Next time I will use my heavy cast iron Hart rest. A consistant hold on rifle is very important, especially when bullet is moving at a slower 1800fps. Best groups were shot using light pressure on grip and shoulder. Trigger needs to be lightened also.

Attached Files

The Vectan AO powder looks promising. Good start to your project. Keep the reports coming. John

Attached Files

Powder charges (not individually hand weighed) were thrown using RCBS powder measure with smaller pistol insert. The square flakes meter easily and accurately like ball powder.

Attached Files

After many years, I recently began to activate a heavy-barrel 220 Swift, with the rather insane idea of trying cast bullets. I'm thinking that if Joe Brennan is having trouble and frustrations, what kind of a chance to I have with this (totally unsuitable) cartridge of getting suitable accuracy? I was able last century (ca. 1955 or so) to achieve accuracy with a different rifle, but didn't know just how hard it could be; my accuracy was just dumb luck. But--I still have my old Lyman moulds, and just for the frustration of it, I intend to cast up some bullets. I don't believe that John Alexander is going to lose any sleep worrying about my showing up at one of his matches, but I thought I'd try to replicate my earlier results, with an entirely different rifle, intrinsically more accurate rifle. We'll see.

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

That's the ticket! I look forward to hearing how that goes. Good luck.

Attached Files

My groups are improving. In this picture I was practice shooting for score without official target (5 minutes rest between each group). Shooting conditions calm and overcast. All charges were thrown with RCBS powder thrower (not individually weighed). 223 Remington brass sized full length. Winchester primers 6.5 Grains of Nobel Vectan A-0 powder Xlox 2500+ lube...Lyman Moly lube may have shot better Lawrence brand magnum birdshot alloy (4-5 percent antimony, 2 percent tin added) LBT custom bullet 62gr

Attached Files

Bill, Don't let the big case bluff you. I think the need for having an appropriate i.e. small case is overemphasized. (Not that I wouldn't buy a Hornet or Bee is someone made them with a 8 or 9 inch twist.) I got some pretty fair results with a 22-250 back in the 1980s. I think the slow twist held me back more than the large capacity. The load I am currently playing with is only 18% of the capacity of the 223 case. The worst disadvantage is that I am not sure I can reliably detect a double charge by shinning a light in the case and have gone to weighing the loaded rounds to be sure. John

Attached Files

Tonight I changed out the lube in my RCBS lube/sizer to LBT soft Blue. Maybe I will get consistent dime size groups doing so.

Attached Files

moly lube ...with my rimfires i used it so that i could seat the bullet deeper in the throat ... not the case .... because it is real slick ...anyway i started out using too much and thought the buildup caused larger groups . but i could just push one rag through the barrel every 50 shots to do better . i wound up putting a teensy amount on every third 22 bullet for best results .

keep going ... i never got under 1.5 moa with any 22 cast ... hornet, 222, bee .

edit: heh the above sounds as if i was seating the bullet out further in a rimfire ... actually i meant i was short-and-tight throating the chamber . almost to the brass, in fact .

Attached Files

The moly lube clings to the inside of my Forster bullet seater. Causing some lube to be pulled out of lube groove. Otherwise I like the Moly lube. I will try less next time.

Attached Files

Okay Guys, all this talk about 22s has the amateurs jumping in. Back in the J world and at a younger age my interest was in making 22s run very fast and strait. I have a few that shot jacketed very well, so I thought I'd move down from the thirties for a bit. First try was with my Savage 22-250 one in twelve twist Lee 55gr Bator 6gr TiteGroup and powder coat. Good plinker. On to the smaller cased 223 Same 55gr Bator powder coated this in a one in nine twist using 7.5gr Unique. I got a .410 buckshot pattern at 50yrds. with a ten shot try. Next up same load with Saeco green in the gas check groove and powder coat down to 3" Gets better or I wouldn't mention all this. Next up everything the same but used 13.5 RL 7 Powder coated 6 shot group 2", powder coat with Saeco lube in check groove 1 1/8” six shot group at 50yrds. Nice cluster and a flyer to open it up to 1 1/8. I'm the biggest powder coat fan here but it seems a little “slickem don't hurt" The great experiment continues. GP

Attached Files

I bet the powder coating will work verywell if you can coat bullets evenly. Is it legal to use under CBA rules?

IMO the biggest cause of group shifting when shooting cast is caused by fouling in barrel. I may coat the inside of my long 26” barrel with Lyman Moly lube and retest the Moly lube.

I found out that I was not flairing case enough causing lube to be shaved off during seating bullet. This caused excess build up of lube inside Forester bullet seater.

Attached Files

OUB12 Your observation on case flaring mirrors mine. One sure way to cause imbalance and most likely leading when using PC'd bullets is to shave the coating when seating. I go one extra step after expanding with the M-Die. Before seating I take the sharp edge off the case mouth by just kissing it with the Lee universal expanding tool to round over the edge. This solved my paint shaving problem. Okay, back to 22s. My thread wander is over for now. GP

Attached Files

Here are more groups I shot for score on the same day. Only change was larger charge of AO powder (7.5 grs). Groups are starting to get larger at faster velocity. I will use Croni next time out.

Attached Files

ou812 ... send me your bad targets ... i will put them on my bragging wall and tell everybody i shot them .....

ken

Attached Files

Right now, I've determined that the Swift case will, in fact, shoot cast well. John Alexander, to underscore my unqualified opinion, also feels the Swift has accuracy potential. That, and John's encouragement, will at least get me re-started. It begins to look as if my old, old group of Lyman dies, while once all that was readily available, may have been badly outclassed/outdated by new manufacturers, and design improvements. If I can't get results with these antiques, (in this case I'm talking about the moulds, not me personally) I'll probably be asking for other ideas and/or manufacturers. (Boy, I love this list!) Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

Well, after buying a new g,h,and I setup for the lubrisizer, I managed to cast some .220 Swift bullets. I would like to believe that my segregation of wheel weights eliminated all the zinc, but............

In any event, I cast a small supply of all 3 moulds I have. I seemed to remember that the 225438, (the ugliest of them all) actually shot the best. So, I loaded a few of the 438's, and the 225415's, only 10 each. (After all, I was very unsure what to expect.) I used my load of 10.1 gr. of 4759 from the mid-1950's, (whatta memory!) and really didn't employ the care usually used in loading cast. I was really pushed for time, (somewhere, a strident voice kept saying “when are you going to get the tomatos planted?)

The only concession to accuracy was indexing already fire-formed cases, and, to save powder measure setup time, powder was weighed.

Bottom line: a nice, round, 3 inch group, with 2 sets of doubles, and one triple. Great start, great place to start load development. I'm hoping for a great deal better in the future.

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

Shooting for score is lots of fun, especially when you can hit the bullseye. Today I got 100 LBT bullets ready to test again. Next time I will try Alliant #7. All bullets pictured from nearest cavity weighed 62.9-63.0 grains, farthest cavity weigh 62.7-62.8 grains before seating gas check. I separate bullets by cavity. Magnum birdshot alloy. Each bullet was inspected for sharp fillout before sizing and seating gas check “nose first” thru Lube-a-sizer using 22cal RCBS nose punch as pusher. Next I lubed bullets “base first” in Lube-a-sizer using LBT Soft Blue. All gas check skirts were sanded square and sharp before installing.

Attached Files

I passed another step in my conversion to cast today. Since moving over to the cast bullet side I've been reluctant to include my 22cal. rifles, especially my 22-250s (I don't see many featured in the fouling shot matches) Well they shoot jacketed very well so why not. I loaded up some Lee 55gr. Bators, Powder coated and gas checked, ten each 15gr SR4759 and 15gr. IMR 4227. These were sized .225 and seated to cover the gas check and the first driving band. With both powders five shot groups went under 2 moa. No big whoop for you bench guys, but for a first try out of my Savage Model 112 heavy barrel I'm pleased. GP

Attached Files

You can't be doing too much wrong with under 2” on first try. I think worrying about the disadvantage of “over capacity” cases for cast bullets is probably over done. I used to occasionally shoot CBA postal matches with a good Ruger #1 in 22-250 . Don't remember exact results without digging into notebooks but I didn't come in last against the rest all using the correct bore size.

Do you size after powder coating?

Gas check before or after coating?

Hope to hear more of your results.

John

Attached Files

John, I size after coating. As for the gas checks I have a system worked out using two 1/4” aluminum plates. One plate is left flat and the second is drilled with a grid of holes to accept spent 22lr casings. the plate with the holes is covered with foil and the holes opened with a punch. The spent casings are placed in the holes and the rims pinched between the plates using screws and wing nuts on the corners. The gas check shanks are inserted in the case necks to cover the shank area. If the casings are a little tight to accept the shanks open with any handy punch (I use the expanding mandrel from my Sinclair neck turner) Then I spray coat electrostatic and bake leaving the shanks bare. This sounds more involved than it is in practice. I see no harm in checking first then coating (sticks them on good) or coating then installing the checks if the shanks are a little small on your bullet. I'm going to give my best 223 a try next as the 22-250 experiment went well. Thanks to all for your help and encouragement. GP

Attached Files

Very clever little gadget you have invented. Thinking up such things to cope with cast bullets is part of the appeal. John

Attached Files

Well, I've started down the long road to accuracy with the .220 Swift. I don't really know why, but I tried a couple of totally unsuitable powders with it; IMR 4064, and IMR 3031. These powders both worked well with Sierras 50 and 55 gr. bullets, in days of yore. I was shocked and overjoyed to find that I got 10 shot groups at 100 yds. sub-2” in size. (Barely!) I used 22 gr of 4064, and 14 gr. (?!) of 3031. The latter load impacted some 5” lower than the heavier 4064 load, which also produced more recoil. (The heavier load was about like a .22 Magnum, the lighter like a .22 short.) Hardly impressive, except on the target. I'm currently out of bullets, and will cast more in a few days. They'll be different, in that I'm going to try heat-treating them to a higher Brinnell number, vice the ca. 15 I've been shooting. Funny: the powders that worked for me in the .308 (4756, 4227, 4895, etc.) were not as good, relatively, as the named. I even got a 2” group from Trail Boss, which has been pretty spotty in the .308. And so it begins again, looking at another long, long road.

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

That road may not be as long as you expect when you are starting off with sub-2” 10 shot groups. Excellent start for any caliber and many never get to that level.

Strange that the usual suspects for powder didn't do as well as the slower powders. When you run out of other variables to test (joke sign) you might try one of the fast pistol powders to look at the other extreme -- Bullseye,700X, TiteGroup, etc. If that doesn't work at first try them with softer bullets <12BHN.

If you are not already, you will soon be the world's foremost authority on 22 cast bullets in the Swift. Looking forward to your next results. John

Attached Files

Bill: It's sure fun for me to see you working with the swift. Like John said, you are most likely the worlds foremost authority. lol The 22-250 worked pretty well for me, swift is working for you. Who will step up and take on the 22 high power or maybe the 223 short mag. the tinkering about at the bench is what makes this hobby so fun for me. Thanks for your posts on this GP

Attached Files

Gentlemen: Thanks for your confidence and interest. I sincerely hope I don't disappoint. It will be a few days before I can fire up the ol' Lyman furnace, but, in fact, I'm pretty excited about the possibility of something noteworthy. But, I will readily admit that the spectre of joeb's work is hovering over my shoulder and breathing it's cold breath down my neck. If Joe's so frustrated considering all the skills and knowledge he brings to the table--well, I just wonder if I can pull anything like a living rabbit out of the hat. But, as Joe is careful to do, I'll tell the good and the bad. Maybe we will all learn something.

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

If that doesn't work at first try them with softer bullets <12BHN.

John

I will try diluting my magnum birdshot (13-14 bhn) with pure lead to see if softer improves consistent accuracy. I have not test my 223 lately because of another 308 project.

Attached Files

bill ” mr. swift ” :: re: joeb and 22 bullets .... don't forget that while joeb has not attained his lofty goal of a lot of 1 inch groups ..... he did come up with a combination that most of us more casual cast shooters would be glad to accept as just fine ...

if i grab a mold, some mystery lead alloy, and keep all the castings that don't have teeth marks on them .... drop in 5 or 10 gr. of unique, ... i will mostly get 2.5 to 4 inch groups .... sometimes at 50 yards .... ... so please don't mind if i regard you and johna and joeb ...and a few others ....as people who have already accomplished what i keep thinking i might someday see in my targets ... groups i can cover with one hand ...

keep it up, i am only a mile or so behind you guys ...

ken

Attached Files

Hi, Ken: Having seen the groups posted here, by Joe and others, believe me, I'm fully aware that some very good work has been, and is being, done. I am envious of a lot of targets displayed. I feel that the magic word here is “Swift". If I were chambering anew, I might be tempted to go for the .219 Donaldson Wasp, (if anybody still has reamers for it) or something of the like. But, I've liked the Swift for many years, having felt it to be much maligned and spoken badly about, and, finding that my experiences were, for some reason, counter to that of many of the seeming experts who wrote about it in the magazines. (Over the years, I have found that it's much more productive to run a rifle for information about a rifle, rather than a keyboard.) In any event, I'm going to stick with the Swift for awhile, and see what can be done with it, realizing at the same time that we're not talking Industry Wide here, but about one pre-'64 M-70 with a Douglas barrel, target stock built by a 23 year old kid, with a lot of curiosity, and a perverse attitude about bucking the “established experts.” I'm a whole lot older now, but I guess I'm still as perverse as ever.

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

Strange that the usual suspects for powder didn't do as well as the slower powders. When you run out of other variables to test (joke sign) you might try one of the fast pistol powders to look at the other extreme -- Bullseye,700X, TiteGroup, etc. If that doesn't work at first try them with softer bullets <12BHN.

John

John, Your Tightgroup recommendation has shown verygood results so far in my rifle and just 5.5 grains per case will load lots of rounds. This little 224 bullet is very economical to shoot and easier on the shoulder. More people should shoot this Small bore.

Less powder equals less fowling....maybe?

Less lube equals less fliers...maybe?

Attached Files

Glad that Titegroup looks promising for you. Now, if I could only find some to buy.

Yes shooting small bore CBs does have its advantages along with the frustrations experienced by some.

If you like to shoot lots of rounds, recoil is certainly one of the advantages. Even the 270 I hunt with and 130 grain bullets seems to be much more unfriendly that it was twenty years ago - must be the new improved powder.

John

Attached Files

Here in Idaho, when Bullseye went extinct I could always find some TiteGroup. It worked so well for me that it is now my go-to fast powder. I've used it in everything from 9mm Luger to 444 Marlin (just a pinch not a case full lol) It seems such a good fit in my new found friends, the 22cals. My 22-250 fells like a pellet gun using 5.5gr of TiteGroup. This thread and especially Bill's work with the Swift gave me the nudge needed to move down to the 22s. Thanks guys! The economy and lack of recoil make the centerfires the perfect answer to the rimfire shortage. GP

Attached Files

Another nice thing about the .22's: notice how you can cast, cast, and then cast some more, and the level of the melt doesn't seem to change! I'm going out next Tuesday with a batch of freshly loaded Swift ammo, and get started on the accuracy trail.Really looking forward to it; I've even added to my tooling. Don't really know why; after all, 1955 really isn't that long ago, is it? It is? HHMMM-maybe I did need to modernize some!<G> Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

I bet plain base 22 cast bullets (12 bhn)would be deadly accurate if velocity was kept under 1500 fps. No gas checks to fall off during flight. I may have one of my LBT cavities opened. Titegroup burns very very clean...less powder fouling inside brass and barrel I am sure. .

Attached Files

Nice looking bullets. Is it normal for the gas checks to come off these little .22's? I recovered two the other day from my steel targets. One from 150 yards, the other from 200. I wonder if using aluminum vs copper would have anything to do with it. With these I also powder coated them and it is a lot more difficult to pull the checks off vs non powder coated bullets.

Attached Files

One Lyman reloading manual shows how to epoxy gas checks onto cast bullet before crimping and sizing. A small syringe or toothpick should work good at applying a slow setting STRONG epoxy to gas check. Just a little dab will do.

Annealing will help also.

...

Attached Files

One Lyman reloading manual shows how to epoxy gas checks onto cast bullet before crimping and sizing. A small syringe or toothpick should work good at applying a slow setting STRONG epoxy to gas check. Just a little dab will do.

Annealing will help also.

...

So is it normal, or just something that sometimes happens - sporadic? I am just curious as I have never had it happen that I know of, but if its a common occurrence with the .22's it makes me wonder about some of the fliers I get now and again.

Attached Files

annealing alum. gas checks ...

my crafty friend john goodrich finds annealing his alum. checks ... adds greatly to his results. has to be done after forming not in the sheet.

they are workhardened during forming .

just a thought.

ken

Attached Files

I shoot probably 80% of 22 bullets with gas checks over a lighted Crony in a tunnel. Mostly Hornady but sometimes coper Gaters or Al from __ ? I have never seen any indication that the gas checks are coming off and hitting the Chrony or the lights. Also haven't found any in the tunnel. I have never annealed a gas check. Nor a case in many years.

Is this a solution looking for a problem, or are others doing something different?

John

Attached Files

annealing gas checks probably needs a separate thread ... maybe an old one added to ??

my buddy john g. is very persnickety so i think he needs his checks annealed ....he sends me pics of his improved targets .

maybe fix it only if it's broken ??? heh .

i myself have no iput as i haven't used gc for 15 years ...

ken

Attached Files

Yea, I am not thinking I will start annealing. i was just curious if it was a common(across the caliber range) gas check issue, or one that is more likely in 22's.

I would think that a gas check coming off in flight would result in some real wild points of impact. I suppose just an inch or two off the mark would not seem likely.

On a side note, did some reading on here over the weekend and found something interesting. Seeing how this thread is entitled “223 UPDATE” maybe its fitting???

I read where someone was doing testing with the little 22's without any lube, just a gas check. How did that testing finish up? I think I might just have to run a few myself to see what happens....might hate myself for doing so in the end....

Attached Files

Nice looking bullets.

Is it normal for the gas checks to come off these little .22's? I recovered two the other day from my steel targets. One from 150 yards, the other from 200.

I wonder if using aluminum vs copper would have anything to do with it. With these I also powder coated them and it is a lot more difficult to pull the checks off vs non powder coated bullets.

I'm not surprised that those gas checks came off. They appear to have been turned inside out! I have seen many bullets that have shed their jackets, and ramming into a steel plate at speed seems like a good reason to do drop your gas check or lose your jacket. It seems to me that the gas check is probably the only solid part left of the bullet except maybe a little disk of lead alloy. At least nobody seems worried about why the bullet “disappeared." Brodie

B.E.Brickey

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

John Carlson 22

-

linoww

17

linoww

17

-

Bud Hyett

14

Bud Hyett

14

-

drone 9

-

MP1886 7

-

beltfed 6

-

Lucky1 6

-

RicinYakima

5

RicinYakima

5

-

mashburn 4

-

Aaron

3

Aaron

3

but

but