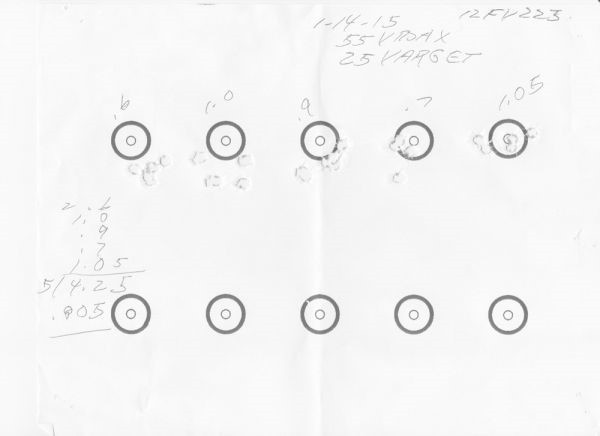

After 2 years, 7 molds, lotsa donated bullets I can't reliably shoot five 5-shot cast bullet groups at 100 yards under 2” average. Including NOE 277-80. This is my second max effort, first started in 2003. I loaded Horn 55 gr VMAX, 25/Varget and shot yesterday. 5 groups 100 yds averaged .85". (pic math wrong) It ain't the gun. Making a 22cf shoot cast is not easy, at least for me. I wonder how the 1” guys do it.

223 UPDATE

- 26K Views

- Last Post 19 January 2016

Attached Files

Joe, Sorry to hear that the NOE bullet didn't improve your luck. How you, and others, can shoot a 311299 in a 308 with your recipe but a near scale model of it won't work in a 223 is strange. I lap or beagle until I get at least four land marks on the nose near the front, use an alloy of 12 - 15 bhn, size .226” for my rifle, give it enough length and neck tension so the bolt is hard to close, try for 1,400 - 1,600fps with a fast, clean burning powder. Sometimes a thin layer of LLA helps for some reason. I suspect that you are already doing all that and more. I can't think of anything else unless it is sporter wt. barrel that doesn't like heavy slow bullets. You might try a shim under the barrel at the forend to change things.

I hope others will join in this discussion. Several shooters are now shooting the 22780 but I don't know how well.

John

Attached Files

Joe, Is that action bedded? You probably have covered this before but just thinking out loud.

Longone

Attached Files

Keep John talking. I'm writing this stuff down.

Attached Files

What type of rifle is it?

I once had some 55gr. jacketed Nosler Ballistic tip bullets that measured an unusually large diameter of.225. These bullets were extremely accurate and shot like a laser beam creating .250” groups very easily. Smaller diameter jacketed bullets of .224-.2243 shot larger groups much like those in picture above. Gun is a factory Remington VS chambered in .223 Remington.

Round bullets, snug fit and shooting skills is key to shooting better groups with cast. “perfection"

Attached Files

As per John's request I have shot the NOE 80 spritzer some in my custom barreled Savage this is a McGowen 8 inch twist barrel with the Wylde chamber. I tried Bullseye, Red Dot, Green Dot, Unique probably a few others it didn't really start shooting good until I got to the Blue Dot. Six grains of Blue Dot put 10 shots in to .900” at 100 yards but I don't have enough Blue Dot to continue testing I only had about enough to load twenty or so rounds. If some ever shows up around my part of the country I try it some more. As of now that rifle is back on coyote duty with well never mind.

RB

Attached Files

I have also had good luck with 6.0 to 6.7 grains of Bluedot and used it in competition with my 85 grain Mos bullet which is a lot like NOE 80 SP for a couple of years before running out.

John

Attached Files

John,

What twist is your barrel? If the target above is correct the load of 25 grains of Varget is a pretty stout one for a lead bullet I would think. If Joe's FV is a 9” twist it would really be spinning that little bullet.

Longone

Attached Files

Joe's 25 grain Varget load is with a 55 grain Vmax jacketed bullet,not one of his CB loads.

The twist in my rifle is one in eight inches but one in nine will also work with the NOE 80 SP. The eight inch twist shoots 35 and 40 grain Vmax bullets well. I don't think spinning bullets too fast is a problem for most of our shooting -- spinning them too slow obviously doesn't work.

John

Attached Files

Thanks John,

I overlooked that he was shooting jacketed with that target. The reason I asked about bedding was because of the windage groups, it made me wonder in what order they were shot. Usually a side to side group indicates shifting of the action in the stock. All groups except the 4th one displays that shifting.

I do believe that you can over rotate a bullet to the point that accuracy is affected. Obviously the 80 gr. bullet needs the extra twist to stabilize because of the length but the shorter bullets do not need the faster twist. Smaller lighter bullets do well with slower twist as shown by bench rest shooters.

I'm sure Joe has done this but perhaps starting with a load that is at the bare minimum and working up very slowly.

BTW, has he swapped out the scope to verify it's not the problem?

Longone

Attached Files

The greatest examples of over rotation I have seen or heard a bout were: A 22-250 and a 220 swift. Both were shooting light (35- 40) gr bullets at extremely high velocities. The bullets flew apart on the way to the target. I personally think that this is why most of those rifles in those calibers have such slow twists. As compared to the .223. Brodie

B.E.Brickey

Attached Files

What type of rifle is it?

SAVAGE 12 FV VARMINT WEIGHT BARREL

I once had some 55gr. jacketed Nosler Ballistic tip bullets that measured an unusually large diameter of.225. These bullets were extremely accurate and shot like a laser beam creating .250” groups very easily. Smaller diameter jacketed bullets of .224-.2243 shot larger groups much like those in picture above. Gun is a factory Remington VS chambered in .223 Remington.

Round bullets, snug fit and shooting skills is key to shooting better groups with cast. “perfection" I have tried this with the original barrel, 2 223 sporter weight 22” barrels and a heavy varmint 22-250 barrel. None worked = <2” 100 yard 5 shot 5 group averages.

Attached Files

Joe, Is that action bedded? You probably have covered this before but just thinking out loud.

Longone Inspect stock for obvious problems-never found one.Savages are pillar bedded. Put the gun in the stock, pull it back and forth-it should move a few thousandths. Want the recoil lug to hit the stock. Start the stock screws. Pull the action back and screw the REAR screw in while holding bbl and stock, you should feel the bbl move UP. When the screw is sorta tight, front screw, feel bbl and stock. BBL should NOT move up or down as screw tightens. Tighten both screws until farting noise is heard. Bbl-stock dollar bill test. Tang, stock dollar bill test.No Savage stock that fits this way is accuracy-helped by any Devcon or epoxy antics.Savage stocks are ~$30 delivered, see Savage Shooters forum. Many hours and Dremel tools and devcon/plumbers epoxy/epoxy paste etc later and cutting off various stock parts north of the recoil lugs are currently residing in the dump. Marlin Bassett was right, pillar bedding works.

Attached Files

Savage factory stocks with pillars in my experience are all too short to do any good. None I have seen contact metal to metal, and even if they did it would be like setting the action on top of a pile of rocks with no side support.I have attached a pic of my bench rest stock bedding. That stock was built for a Savage Target action, the tang was free floating as was everything in front of and including the barrel nut. The screws were torqued 30 inch lbs. front and center with the rear screw having 5 inch lbs. This rifle was built in 6mm BR and shot .200” 5 shot groups @100 yds. with 68 grain bullets (jacketed). In the bench rest game you don't see fast twist barrels or heavy bullets @ 100 or 200 yards in the winner circle. Savage actions are on the light side of strength so bedding to support them is pretty critical if accuracy is what someone is after, any movement in the stock will change the harmonics and point of impact. Longone

Attached Files

Maybe we are cleaning our barrels too often? Cleaning less may help.

Off to the range I go.

Attached Files

I cut a longer .150" freebore in one off my factory barrels to see if this would help guide the bore riding bullets better. Used 4 different cast bullets (225646, RCBS 55gr, NOE 45gr, Lee Bator 55gr) sized .0001-.0005 smaller than freebore diameter and using same powder charge of 16.5gr 133. All bullets bore ride section had a snug slip fit. Here is my best 10 shot group using the Lyman 225646 lubed with thinned hand dipped Alox. Groups did not improve over factory chamber, but different gun also.

Attached Files

sigh ... your reject group is better than my best lifetime cast group !! ( not counting those mysterious 22 rimfires ) ...

what did your chamber wind up looking like ?? are you getting most of your bullet engraved before firing ?

the questions keep changing faster than we can think up answers ( g ) ...

ken

Attached Files

<user=40>Ken Campbell Iowa wrote: sigh ... your reject group is better than my best lifetime cast group !! ( not counting those mysterious 22 rimfires ) ... what did your chamber wind up looking like ?? are you getting most of your bullet engraved before firing ? the questions keep changing faster than we can think up answers ( g ) ... ken Rifling engraves bore ride section when bullet's front band touches rifling (22 Bator in picture) According to pound cast the free bore now measures .2253” diameter and .150” long. Groove diameter of Remington 1/12 twist barrel is .2245". This barrel is a take off factory barrel that originally had a crooked cut throat. The PTG Throater cleaned up rifling very nicely and evenly. A large .2193 pilot bushing was used on throating tool to help center best. I now full length size my brass for this barrel to counter crooked cut chamber...tight fitting bullet in throat now centers everything before firing. I will eventually cut throat deeper and try longer bearing surface spitzer bullet sized .0001-.0005 under free bore diameter. Hopefully it works? The gun started shooting its best around round 40-50 (see target above)...when barrel was its dirtiest. Hawkeye bore scope shows no leading in barrel. There was a little alox lube star at crown of barrel after test, so lube is plenty...I think. I will not clean this barrel and test again. Seems that Lyman Moly lube did a little better in grouping department about 3 weeks ago, but in a different rifle.

Attached Files

Savage factory stocks with pillars in my experience are all too short to do any good. None I have seen contact metal to metal, and even if they did it would be like setting the action on top of a pile of rocks with no side support.I have attached a pic of my bench rest stock bedding. That stock was built for a Savage Target action, the tang was free floating as was everything in front of and including the barrel nut. The screws were torqued 30 inch lbs. front and center with the rear screw having 5 inch lbs. This rifle was built in 6mm BR and shot .200” 5 shot groups @100 yds. with 68 grain bullets (jacketed). In the bench rest game you don't see fast twist barrels or heavy bullets @ 100 or 200 yards in the winner circle.

Savage actions are on the light side of strength so bedding to support them is pretty critical if accuracy is what someone is after, any movement in the stock will change the harmonics and point of impact.

Longone

So, tell us how much the bedding reduced group size.

Attached Files

I cut a longer .150" freebore in one off my factory barrels to see if this would help guide the bore riding bullets better. Used 4 different cast bullets (225646, RCBS 55gr, NOE 45gr, Lee Bator 55gr) sized .0001-.0005 smaller than freebore diameter and using same powder charge of 16.5gr 133. All bullets bore ride section had a snug slip fit. Here is my best 10 shot group using the Lyman 225646 lubed with thinned hand dipped Alox.

Groups did not improve over factory chamber, but different gun also. Is this about a 2 3/4” 10 shot 100 yard group?If so, it's kinda like what I'm shooting.My groups are enlarged with flyers that make the average BIG!

Attached Files

My best 10 shot groups in .223 are also with the 225646 checked and tumble lubed. My rifle is an NEF Ultra Varmint with the older 1:12 twist and will do just under 1” @100 yards. JoeB has tried this bullet and written it off as not terrific in his rifle. I don't think it is just our particular rifles that like this terrific bullet. I think it is a great bullet with a nice short nose and a long bearing area that casts large and is sizable correctly for many rifles. Mine finish at 59 grains all up in #2 alloy with an Aluminum check and 45:45:10 tumble lube.

I lucked into a sale on that mold years ago and haven't looked back. It shoots for me.

Gary

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

John Carlson 22

-

linoww

17

linoww

17

-

Bud Hyett

14

Bud Hyett

14

-

drone 9

-

MP1886 7

-

beltfed 6

-

Lucky1 6

-

RicinYakima

5

RicinYakima

5

-

mashburn 4

-

Aaron

3

Aaron

3