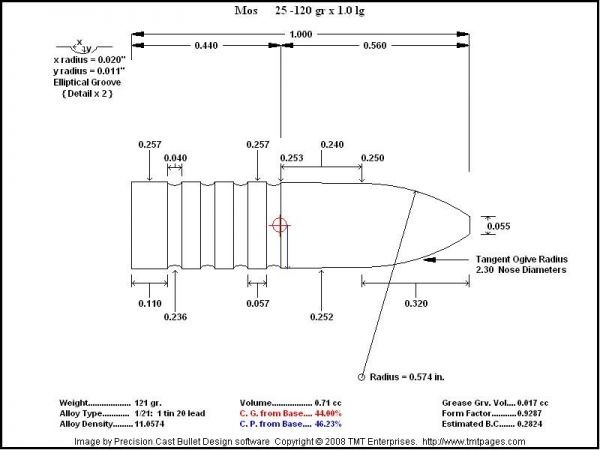

I posted this on the NOE Forum and have thought about for many years. I would be interested on this forums thoughts about it. If there are any areo engineers, I would like to get some real figures regarding it. The shock wave is a real thing and takes a great deal of force to push it and increases with speed. It's also the reason that subsonic looses so little velocity. “One thing that I would like to bring up about this design is the tip of the nose. I put the radi on the nose edges because I have suspected that sharpe edged, smaller meplats may be prone to deterioration at ~Mach 2 velocitys. I did a little research last week and found that at Mach2 (2240 fps at sea level), the Concord jet was producing temp increases on it's nose of approx. 350F. They measured with sensors set all over the aircraft. The nose of the Concord has a lot of mass to soak up heat, much more than a bullet.I believe at Mach2 + velocitys, that the sharpe edge of the lead meplats can get much hotter than that and possibly melt. Remember that the nose temp is added to the barrel friction and the hot powder gases at the base of the bullet, then add ambient temps to that. The nose can take a real beating with those temp increases plus the force that it takes to push that shock wave. Frank"

meplats can get much hotter than that and possibly melt. Remember that the nose temp is added to the barrel friction and the hot powder gases at the base of the bullet, then add ambient temps to that. The nose can take a real beating with those temp increases plus the force that it takes to push that shock wave. Frank"

HV Nose shape

- 7.3K Views

- Last Post 14 December 2014

Attached Files

Frank;What is the design for? What is the goal? BS or fixed? High BC? Shoot as cast? What are you trying to do?Thanks;joe b.

Attached Files

I would think the bullets need only travel 100 or 200 yards depending on the range. The Concord wouldn't even be off the runway in that distance.

Attached Files

I believe that the Concorde is motionless. Another ?good? idea bites the dust. I, myself, never gave a rat's oss if rich people could cross the ocean fast. Are they staying home now?

Attached Files

The goal is a bullet that can be shot BS or fixed at HV. It will work fixed in a long throat or a about a .380 long neck.

Also a better BC as not many CBA match bullets have that in this weght range.

The Concord weighs tons, this bullet weghs 170 gr, much less mass to heat up. Stick you hand out a window at 80+ mph, you'll feel your shin heat up in just a few yards. The sonic barrior is a real thing it both hard to push and hot.

Frank

Attached Files

Frank's question is an interesting one but probably one of those questions that doesn't even start to lend itself to solving by trying to reason it through. We may think we are getting somewhere but the problem is just too complicated to get a handle on it by just thinking. Maybe that wouldn't be true for a very specialized aerospace engineer but just the questions of heat transfer and the very short time involved as Bill mentioned puts it out of the range of us common mortals. That doesn't stop us having opinions of course.

If we could catch a few bullet (with and without sharp points and with and without sharp edges to the meplat) in a medium that wouldn't deform the bullet (Mann and Martin used oiled sawdust) we could get some answers in an afternoon.

Code the type of bullet with colored bases. Set that catcher up at 200 yards and blaze away. No doubt easier said than done.

John

Attached Files

I wouldn't think it would be a problem for a skilled (and possibly also unskilled) machinist to chamfer a controlled radius on the nose meplat edge of , say, the NOE 310-165 FN (xcb) bullet. That would at least enable you to do a shooting comparison to determine if there's any performance and/or accuracy differences. I've been shooting this bullet sub-moa in the Mach 2.16 range recently, and it would be interesting to see if induced skin temperature indeed has an effect. On regular (subsonic) jets cruising in the high 30's, the difference between SAT (static air temperature) and TAT (total air temperature, SAT corrected for heat generated by the aircraft's skin) is usually around 25-30 degrees C. With a SAT at -60 you normally end up with a TAT around -30. FWIW.

Attached Files

I wouldn't think it would be a problem for a skilled (and possibly also unskilled) machinist to chamfer a controlled radius on the nose meplat edge of , say, the NOE 310-165 FN (xcb) bullet. That would at least enable you to do a shooting comparison to determine if there's any performance and/or accuracy differences. I've been shooting this bullet sub-moa in the Mach 2.16 range recently, and it would be interesting to see if induced skin temperature indeed has an effect.

On regular (subsonic) jets cruising in the high 30's, the difference between SAT (static air temperature) and TAT (total air temperature, SAT corrected for heat generated by the aircraft's skin) is usually around 25-30 degrees C. With a SAT at -60 you normally end up with a TAT around -30. FWIW.

We need to know more about shooting sub moa at 2400 fps. Gun, load, all of it.Maybe on a new thread.Please?joe b.

Attached Files

Frank;Here are some thoughts:We over emphasize the importance of BC/wind drift, a lot, at ranges to 200-300 yards.To increase BC = reduce wind drift we can change bullet design or velocity or density. That's all we can change.Your bullet, for example, at 1500 fps, would have wind drift reduced by half if the design changed and BC went to .6 or MV went from 1500 fps to 2400 fps. I suspect that getting rid of grease grooves and bands, and making the nose pointy = meplat smaller, would increase BC a lot, and easily. I know that increasing bullet length would increase BC, since, ceteris paribus, BC varies directly as length. For me, high CB velocities have not accompanied accuracy. All of which gets us to 31X299 or something close, but we've been there for many years. or

Attached Files

i suppose somebody somewhere knows what happens to soft point 224 bullets from at 220 swift at 4000 fps ... maybe hornady ? when i could see better, i think i saw glowing bullets at night from my pop-gun 222 at 3000 fps. but barrel heat ? not air friction ? interesting.

maybe if the points melt, the bc would change during flight ...oops .. too simple, as bullets do have different bc at different velocities ...

and, pushing out of my area of certainty ... one reason for a long sleek nose is to move the center of pressure back towards the center of gravity ... less ” leverage ” thus less moment to make the bullet wobble, thus higher bc from a less wobbling bullet.

it might be that for long ranges we would accept a less ” group-accurate ” bullet in exchange for a higher bc bullet ... the wind dispersion at 600 yards can be a lot more than group dispersion. here we see that the most * hit-accurate * bullet might not be the one that groups the best.

interestingly, this concept of actually HITTING something with our bullets ties into my ...rare but joyfull ...mentionment that average radius of dispersion ... should receive at least honorable mention along with the easy standard of the two widest shots.

i would guess that if lead bullets don't melt from barrel friction, they don't melt from air friction.

ken

Attached Files

Ken, One of the things that I'm trying to get at also, is the accumulation of heating (powder gas, barrel friction and the heating in the air), while it's unproven that the point will actually melt, it is a fact that heat will weaken a lead alloy. nose slumping could be a effect of that, although, I haven't seen slumping proven to my satisfaction. Of the three factors, the air has the longest time to work on a bullet, in the area of 1/3 sec for 2200 fps, opposed to mili sec for the other 2 factors. Also, we don't get the cooling effect of high attidude aircraft do and they don't reach those speeds at ~sea level.

Regarding jacketed 4000 fps loads in the Swift and the CHeetha, I remember reading that some of them discentagrated and was atributed to heat.

Frank

Attached Files

Joe,I'm not going to hijack Frank's thread, but I wrote a long thread about this shooting over on the NOE forum, with pictures. Gun, load, bullet, it's all there. I will start a new thread here on the CBA forum when I have more data to share.I wouldn't think it would be a problem for a skilled (and possibly also unskilled) machinist to chamfer a controlled radius on the nose meplat edge of , say, the NOE 310-165 FN (xcb) bullet. That would at least enable you to do a shooting comparison to determine if there's any performance and/or accuracy differences. I've been shooting this bullet sub-moa in the Mach 2.16 range recently, and it would be interesting to see if induced skin temperature indeed has an effect.

On regular (subsonic) jets cruising in the high 30's, the difference between SAT (static air temperature) and TAT (total air temperature, SAT corrected for heat generated by the aircraft's skin) is usually around 25-30 degrees C. With a SAT at -60 you normally end up with a TAT around -30. FWIW.

We need to know more about shooting sub moa at 2400 fps. Gun, load, all of it.Maybe on a new thread.Please?joe b.

Attached Files

i went to noe forum but can't find that post. timed out ? or do you have a link or copy ? thanks

Attached Files

Me too, bjornb. I don't have much time on the computer and don't want to be chasing over to other places. Thanks, Ric

Attached Files

Attached Files

"A longer point would give less head drag and thus less velocity loss in flight, but experience with long points in rifle cast bullets has shown that their failure to align the bullet reliably in heavy loads.”

E. H. HARRISON

This was his reason for the short point of the 311332 and 311334

Attached Files

"A longer point would give less head drag and thus less velocity loss in flight, but experience with long points in rifle cast bullets has shown that their failure to align the bullet reliably in heavy loads.”

E. H. HARRISON

This was his reason for the short point of the 311332 and 311334 That statement would apply to throating such as the '06 standard chambers. I've read most of Harrisons NRA works and I can not remember him doing any work with match type neck, freebores and long leades. Frank

Attached Files

Article “Paper Patch Comes OF Age” He test the Paper Patch 301618 up to 2750fps and the Paper Patch 301620 up to 2440 fps.

Attached Files

Frank;Here's some on alloy temp and strength etc, what happens as the bullet moves I'll send the EXCEL files if you want.joe b.

Attached Files

Although I never like the word “fiddling” connected to factual accounts. The following seems to agree with what I read regarding the measured temps recorded on the actual Concord flight readings as copied from your down load.

"Fiddling with the table of temperatures and velocities in the article, I find the formula to be: Delta T =: Temperature rise above ambient (Degrees F) = V^2(fps)/13310. Means that skin temperature equals velocity squared, divided by 13,310.Increases to T are: V (fps) Delta T 500 19 1000 75 1500 169 2000 300 2500 469 In the example of lead/1.5% antimony with a melting point of 600 degrees F, and an ambient temperature of 75 degrees F, the skin of a lead alloy bullet would become liquid at 2646 fps. The calculated skin temperature falls as bullet speed falls; and that's pretty fast. For example, a .202 BC bullet with 2700 fps mv has skin temperature of 548 degrees F above ambient at 50 yards; and 179 degrees F above ambient at 300 yards when v has fallen to 1545 fps. It seems unlikely that the center of the bullet reaches anything like the skin temperature."

The melting point of Linotype is given as 462-477F so, it would seem that thin, sharpe edges may be be prone to melting with just the air temp increase from muzzle velocity in the 2500 fps range.

I use that alloy because, that is what most sucessful Heavy and Unr shooters are using.

With regard to the friction and powder gas increases, I think that a real measurement will be required, such as a laser reading. I'm only guessing but, I think lead and lead alloys will have a higher thermoconductivity than steel and increase at a higher rate. Frank

Attached Files

Frank wrote: With regard to the friction and powder gas increases, I think that a real measurement will be required, such as a laser reading. I'm only guessing but, I think lead and lead alloys will have a higher thermoconductivity than steel and increase at a higher rate. Frank"

It apparently depends on what steel. For lead it is less than carbon steel but more than stainless. It seems to me that a lower conductivity would make the surface, the part of interest, heat faster. The heat couldn't dissipate as fast to cool the surface. But the time involved for dissipation is very short. Testing and numbers are needed.

John

Attached Files

"A longer point would give less head drag and thus less velocity loss in flight, but experience with long points in rifle cast bullets has shown that their failure to align the bullet reliably in heavy loads.”

E. H. HARRISON"

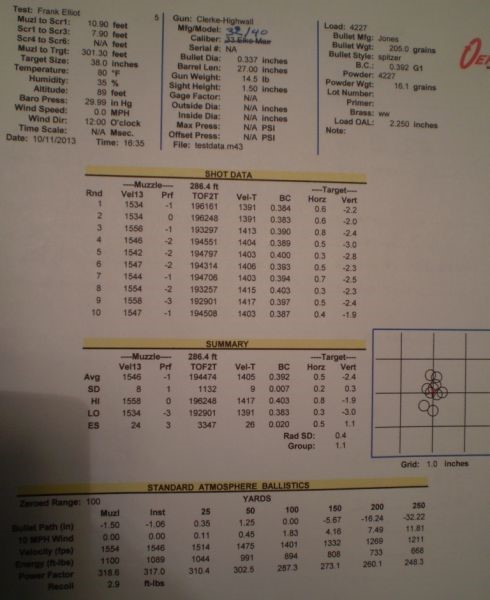

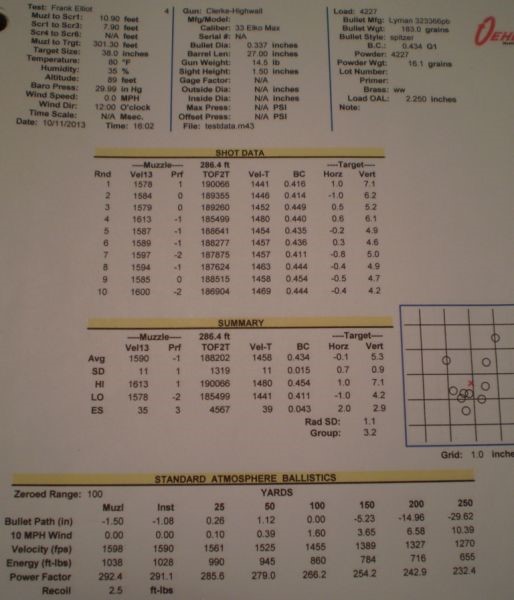

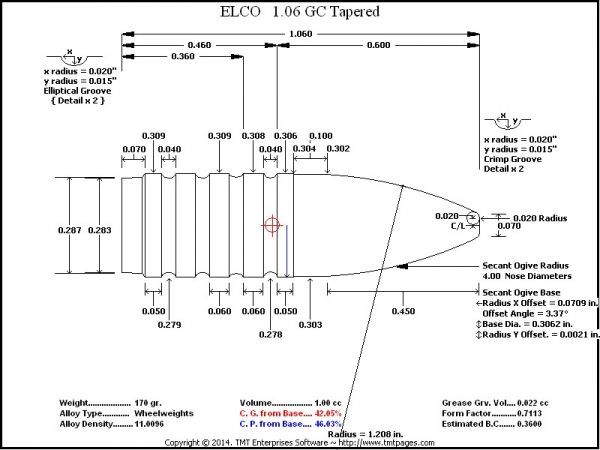

That is also the reason for the nose ogive of the NOE 30 XCB bullet to begin its taper at the leade (beginning of the rifling in my definition of “leade") to the nose w/o any bore riding. The 30 XCB is designed for the standard '06 neck and throat. The computer program in common use (?) that estimates the BC appears to be somewhat optimistic. Apparently it doesn't take into account the drag caused by the lube grooves and really flat base (Joe alludes to this in one of his posts). Nor does it consider what velocity level the bullet is used at. I have determined this having measured the BC via velocity/time of flight measurements with the M43 Oehler using screens at the muzzle and in front of the 100 yard target. The BCs are always less than given and decrease as the velocity increases. The BCs do level off around 2200 fps upwards of 2800+ fps as so far measured. That is just above Mach 2 but I have not hit Mach 3 yet so don't know after that. As to the nose melting from the heat above Mach 2 it does not appear to by the accuracy results obtained by myself and Bjorn in the 2550 - 2800+ fps range with either the 311466 or the 30 XCB. The problem of accuracy at high velocity with cast bullets is a matter of controlling the design of the cast bullet, quality of the cast bullet, controlling the RPM generated at the expected velocity, controlling the pressure and the damage done to the bullet during it's entry into the bore. Both myself and Bjorn have had great success in this area with 14” twist long barrels (27.6 and 30.5") and 2 cartridges; the .308W and the 30 XCB using the 30 XCB bullet which was specifically designed for HV use. LMG

Concealment is not cover.........

Attached Files

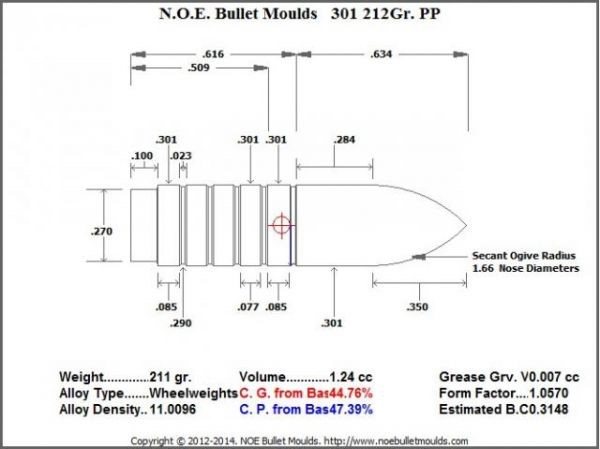

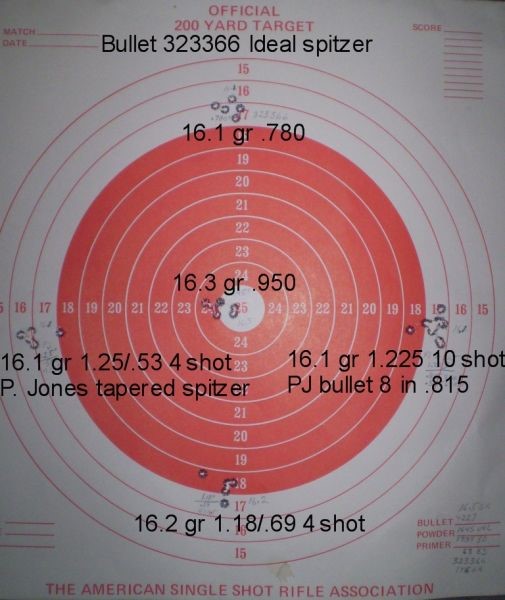

While the TMT program that Al and I use can't be expected to produce exact BC's. You can actually get higher BC's than predicted. (I have 2 others also, that tend to agree with TMT. From Lija and geoffrey-kolbe for jacketed bullets) I've worked with Barry Darr for the last couple of years using his M43 and I have at least 2 examples of higher BC's and one of the bc as predicted. I agree that the lube grooves may have a effect on BC but, there is very little boundry layer attachment at HV. If the bullet has any yaw, in flight, it will produce a lower BC than head on flight. If you look at targets, if you see ANY tipping that shot will have a lower BC, even though it may be in the general group. This bullet has a actual BC of .440 Frank

Attached Files

The first 2 posted belong to friends, the next on is mine and it is amost exacty on the money. Frank

Attached Files

That's an excellent close BC between measured and calculated correlation down at slightly + Mach1 velocity(1554 fps). However I thought your original inquiry (?) was regards to the heat generated at + Mach2 velocity ("at Mach2 (2240 fps at sea level") in comparison to the Concord flight speed? I've found very few calculated BCs that correlate that accurately to calculated BCs when velocities at Mach 2 + (also measured with a M43 Oehler). However, as you point out at just over Mach1 and when sub sonic the BCs generally are very good.

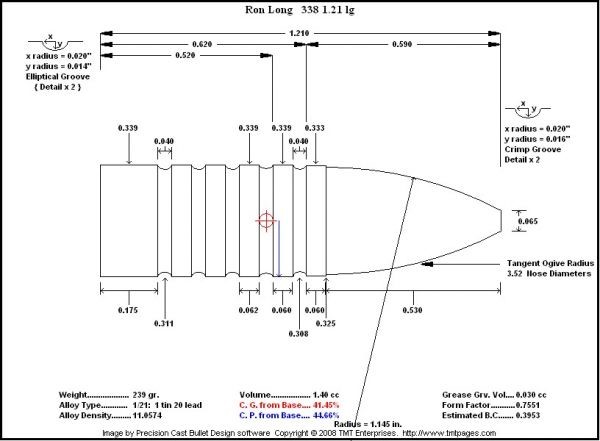

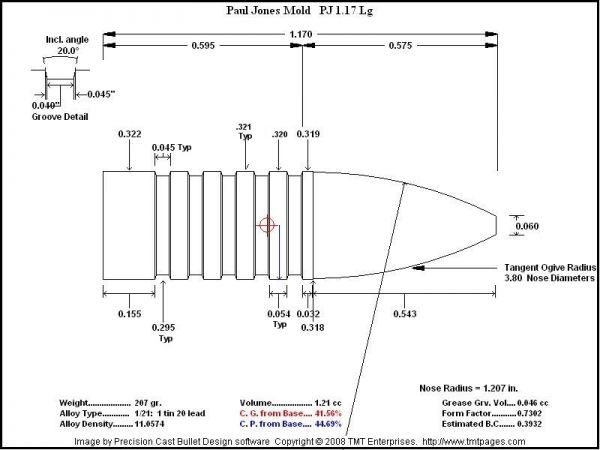

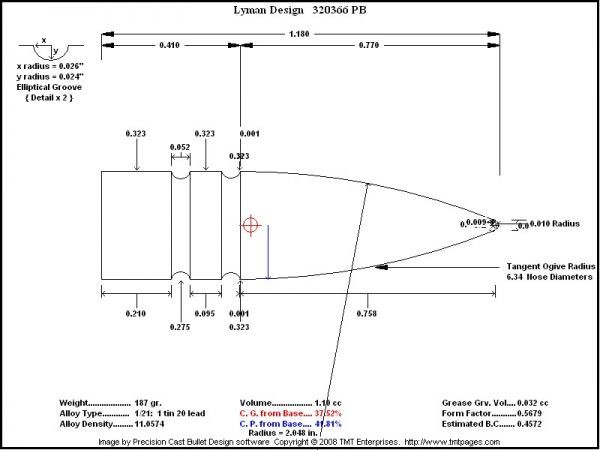

As an example of how the measured BCs differ from the calculated BCs let's look at the NOE 310-165-FN has a listed calculated BC of around .290. Yet when we actually measure the TOF and the BC we find the actual measured BC at 2400 - 2700 fps it is .240 - .250 +/-. Another example is the Lyman 311466 which has a listed BC of .250. NOE lists their 311466 BC at .213. Yet the measured BC of the Lyman is .256 at 1988 fps (just under Mach2), falls to .231 in the 2500 - 2600 fps range and down to .220 at 2800 fps. Thus we see the compression at the nose and the turbulence in the “boundary layer” do indeed have an effect as we increase the velocity close to and above Mach 2.

LMG

Concealment is not cover.........

Attached Files

While this thread is about nose shape, I don't mine it drifting to overall bullet design, thats another aspect to the nose shape of this bullet design. Although it might loose some of it's BC as the velocity goes up, it will loose less BC that other designs with about the same nose lenght. The reason that your bullets loose there BC as the velocity increased is because of the nose shape. It is to blunt, not the size of the meplat but, the chamber shape of the nose radius. If you'll do a little reasearch on supersonic wing profiles (bullets are round wings) you'll find that supersonic wing profiles are entirely different than subsonic profils. The 311466 and the 30XCB (NOE 310-165-FN) have nose profiles much more in tune to subsonic flight. Just because a bullet has a small meplat, doesn't mean that it's BC will be suitable for HV flight. The chamber of the nose (ogive radius) is what keeping the BC down as the velocity goes up. That is why the VLD bullet profiles work so well at HV. Cast bullet design hasn't progressed at near the same rate as jacketed, in part because of the lack of strength of the lead alloys. Along with that is the old and famous shooters and writers that have claimed that spitzer cast bullets will not shoot accurately. that started changing in the 1970-80 era and now, almost no one shoots a bullet with less than a 3 caliber ogive and ~4 caliber is the average. Here is another example of BC's that come close to matching. In this test, the barrel had leaded in fouling (you can see that in the accuracy) it for the test, it was really bad by the time it was over. That may have caused the little bit of miss match.

Attached Files

This is the accuracy that I've gotten with that bullet.

Attached Files

Nice shooting. Have you tried any similar nose shape gas check versions at faster velocities (2500-2700)?

Attached Files

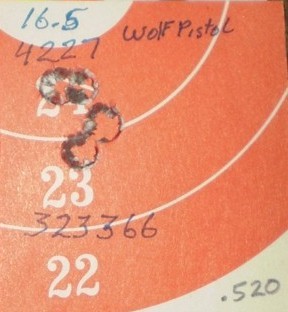

This is a long term (slow) test to see how high that I can take a PB bullet w/o leading and still have accuracy and as what you see on that target, isn't match quality accuracy, I haven't got around to getting back to it. I first posted that target and one other on this forum about 2 years ago, asking for other people involved with higher velocity PB loads. I got no responce in that area, at that time. I started that project about 6-9 months before that after trying that bullet out, WITH the GC on it at 16.5 gr (not much higher vel) and after getting a good group (.520), I reamed the GC off it. This is the group that I started with:

Attached Files

Nice shooting. Have you tried any similar nose shape gas check versions at faster velocities (2500-2700)?

Yes that is very nice but it is still down at 1598 fps. As asked; how does it do at 2500 - 2700+ fps? The GC'd 311329, 311365 and 311413 also all have very decent BC's. However none of them shoot well at anything over 1800 - 1900 fps. That is the problem your experience at low sub Mach2 velocities are not telling you Frank. The 30 XCB bullet was designed expressly with Mach2 + velocity in mind. It has, to quote from another forum, “performed well from day one".

That performance has been with velocities from 2400 up through 2800+ fps now. It is not based on theoretical guesses but based on actual tests at that velocity level. Everyone appreciates your expertise with Schuetzen rifles in the just over Mach1 velocity range. However, what happens there is not what is happening at Mach2 + (which is what you started this discussion pondering about) and very close to Mach3.

LMG

Concealment is not cover.........

Attached Files

Didn't one of the big Jacketed bullet makers design their “MAGTIP” bullets because of tip “slumping” at very high velocity? Speer or Hornady? MY hunting and target shooting with cast isn't up to the need for these type of concerns. I do enjoy reading about the various attempts to get better accuracy or terminal ballistics, even IF I will never need to duplicate them. IF (big IF) I can hit a 1 pound coffee can at 150 yards, I call it good!

Attached Files

” It may be easier to get accuracy with BSed, PB slower bullets, I don't know as we can't use GC's in our shooting.Nice shooting. Have you tried any similar nose shape gas check versions at faster velocities (2500-2700)?

Yes that is very nice but it is still down at 1598 fps. As asked; how does it do at 2500 - 2700+ fps? The GC'd 311329, 311365 and 311413 also all have very decent BC's. However none of them shoot well at anything over 1800 - 1900 fps. That is the problem your experience at low sub Mach2 velocities are not telling you Frank. The 30 XCB bullet was designed expressly with Mach2 + velocity in mind. It has, to quote from another forum, “performed well from day one".

That performance has been with velocities from 2400 up through 2800+ fps now. It is not based on theoretical guesses but based on actual tests at that velocity level. Everyone appreciates your expertise with Schuetzen rifles in the just over Mach1 velocity range. However, what happens there is not what is happening at Mach2 + (which is what you started this discussion pondering about) and very close to Mach3.

LMG

200 Yards, Benchrest200 yards Benchrest:

5 shot group..367” Jeff Schultz 2007

Benchrest, 25 shots in 5 groups, single entry, annual match (summer)1.091” Dale Reynolds 2010

Rowland Match: Benchrest, 10 shots for group, single entry, annual match (spring)1.240” Jeff Schultz 2011

10 Shot Group Match: Benchrest, single entry, annual match (fall).924” Dale Reynolds 2011

There are two 10 shot 200 yard records (don't know why) for 200 yards.

With our slower bullets 200 yards is not easy.Over the year, we don't shoot many matches at 100 yards

100 Yards, Benchrest:

Kelly Match: 5 shots for group.141” Andy Zahornacky 2011

Bartlet Match: (5) 5 shot groups for average0.3882 John Louis 2014

More common match (winning) results will be 1.5-1.75 times these records.

That gives you something to “shoot for", pun intended :) It should be possible with less wind drift at much higher velocity. I'm sure you can get there one step at a time.

Frank"

I posted that on another forum and as it says, HV accuracy should, at least be able to match those results because of LESS wind drift, alone. You've got to work at it with a open mind and try many different things. Another reason that the BC and accuracy is a little off is that the bullets could be degrading, untill you catch a bullet, we will never know. “performed well from day one” doesn't mean that there is nothing left to find.

BSing of bullets at this (2800 fps) velocity is a truly unknow area.

As to my experiance with HV BSed and GCed bullets, I did that in ~1990 with the 323471 at 2150 fps and obtain a small group of .430 and many groups both under and 1” and over up to 2” and I had to size it .004 to shoot it my 32/40.

While in theory, a short fat nose should be stronger, they sure aren't

The 311413 only has a BC of ~.300, while the 311365 may be problematic to BS because of the standard casting size and the OA length of the driving bands, the 311329 is a very good candidate for HV, BSing, especially if you can find a “U” marked one. I have one and would be willing to let bornb try it.

Frank

Attached Files

That's just excellent Frank. Accuracy for the sake of accuracy is just fine and many of us have been shooting very accurate cast loads for many, many years down in that velocity range. You want to stay down there and play then fine, stay.

However, some of us have moved on seeking another challenge; as high a velocity as we can push a cast bullet while maintain a reasonable level of accuracy over extended ranges. You started this thread with a question about bullet noses melting above Mach2. You obviously don't like the answer so you are changing the question now to argue a low velocity accuracy view.

That's fine as already mentioned Frank because most all of us do appreciate the accuracy level you post. You argue here against yourself with all of our backing. You are right Frank, very nice accuracy but not at the speed of the Concord which was what you asked about, eh?

LMG

Concealment is not cover.........

Attached Files

Different strokes for different folks and all that jazz.

You guys have been bumping noggins over on Castboolits for quite a while and if you don't mind I'd prefer you don't do it here. Not that I have anything against a good argument, in fact I love them, but at least be arguing about the same thing which in this case you ain't. High speed vs low speed. PB vs gas check. Single shot vs bolt gun. Hard alloy vs soft alloy. Extreme accuracy vs acceptable accuracy for the speed. Ying vs Yang. Spy vs Spy It's a different set of circumstances and goals.

Attached Files

pat I

No problem here, I think Frank's posted groups are really good and deserving of praise, he has a right to be proud of them. As I mentioned I've no problem with such and truth be known I shoot far more cast bullets out of rifles under 2000 fps than over. Just as you say; “It's a different set of circumstances and goals” is all.

LMG

Concealment is not cover.........

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

John Carlson 22

-

linoww

17

linoww

17

-

Bud Hyett

14

Bud Hyett

14

-

drone 9

-

MP1886 7

-

beltfed 6

-

Lucky1 6

-

RicinYakima

5

RicinYakima

5

-

mashburn 4

-

beemer 4