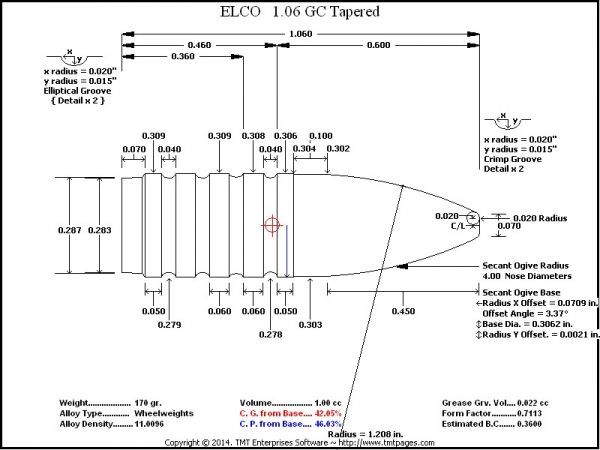

I posted this on the NOE Forum and have thought about for many years. I would be interested on this forums thoughts about it. If there are any areo engineers, I would like to get some real figures regarding it. The shock wave is a real thing and takes a great deal of force to push it and increases with speed. It's also the reason that subsonic looses so little velocity. “One thing that I would like to bring up about this design is the tip of the nose. I put the radi on the nose edges because I have suspected that sharpe edged, smaller meplats may be prone to deterioration at ~Mach 2 velocitys. I did a little research last week and found that at Mach2 (2240 fps at sea level), the Concord jet was producing temp increases on it's nose of approx. 350F. They measured with sensors set all over the aircraft. The nose of the Concord has a lot of mass to soak up heat, much more than a bullet.I believe at Mach2 + velocitys, that the sharpe edge of the lead meplats can get much hotter than that and possibly melt. Remember that the nose temp is added to the barrel friction and the hot powder gases at the base of the bullet, then add ambient temps to that. The nose can take a real beating with those temp increases plus the force that it takes to push that shock wave. Frank"

meplats can get much hotter than that and possibly melt. Remember that the nose temp is added to the barrel friction and the hot powder gases at the base of the bullet, then add ambient temps to that. The nose can take a real beating with those temp increases plus the force that it takes to push that shock wave. Frank"

HV Nose shape

- 7.3K Views

- Last Post 14 December 2014

Attached Files

Frank;What is the design for? What is the goal? BS or fixed? High BC? Shoot as cast? What are you trying to do?Thanks;joe b.

Attached Files

I would think the bullets need only travel 100 or 200 yards depending on the range. The Concord wouldn't even be off the runway in that distance.

Attached Files

I believe that the Concorde is motionless. Another ?good? idea bites the dust. I, myself, never gave a rat's oss if rich people could cross the ocean fast. Are they staying home now?

Attached Files

The goal is a bullet that can be shot BS or fixed at HV. It will work fixed in a long throat or a about a .380 long neck.

Also a better BC as not many CBA match bullets have that in this weght range.

The Concord weighs tons, this bullet weghs 170 gr, much less mass to heat up. Stick you hand out a window at 80+ mph, you'll feel your shin heat up in just a few yards. The sonic barrior is a real thing it both hard to push and hot.

Frank

Attached Files

Frank's question is an interesting one but probably one of those questions that doesn't even start to lend itself to solving by trying to reason it through. We may think we are getting somewhere but the problem is just too complicated to get a handle on it by just thinking. Maybe that wouldn't be true for a very specialized aerospace engineer but just the questions of heat transfer and the very short time involved as Bill mentioned puts it out of the range of us common mortals. That doesn't stop us having opinions of course.

If we could catch a few bullet (with and without sharp points and with and without sharp edges to the meplat) in a medium that wouldn't deform the bullet (Mann and Martin used oiled sawdust) we could get some answers in an afternoon.

Code the type of bullet with colored bases. Set that catcher up at 200 yards and blaze away. No doubt easier said than done.

John

Attached Files

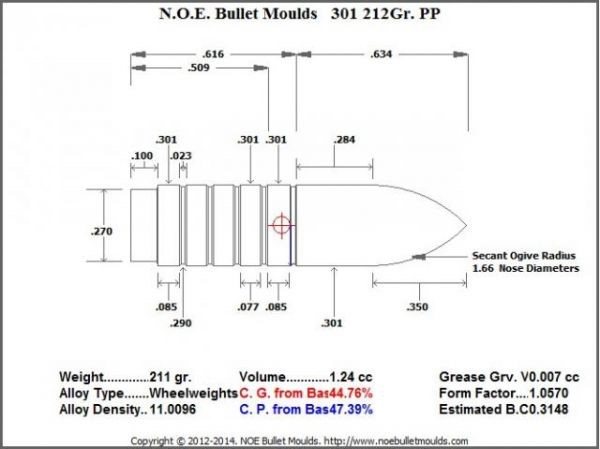

I wouldn't think it would be a problem for a skilled (and possibly also unskilled) machinist to chamfer a controlled radius on the nose meplat edge of , say, the NOE 310-165 FN (xcb) bullet. That would at least enable you to do a shooting comparison to determine if there's any performance and/or accuracy differences. I've been shooting this bullet sub-moa in the Mach 2.16 range recently, and it would be interesting to see if induced skin temperature indeed has an effect. On regular (subsonic) jets cruising in the high 30's, the difference between SAT (static air temperature) and TAT (total air temperature, SAT corrected for heat generated by the aircraft's skin) is usually around 25-30 degrees C. With a SAT at -60 you normally end up with a TAT around -30. FWIW.

Attached Files

I wouldn't think it would be a problem for a skilled (and possibly also unskilled) machinist to chamfer a controlled radius on the nose meplat edge of , say, the NOE 310-165 FN (xcb) bullet. That would at least enable you to do a shooting comparison to determine if there's any performance and/or accuracy differences. I've been shooting this bullet sub-moa in the Mach 2.16 range recently, and it would be interesting to see if induced skin temperature indeed has an effect.

On regular (subsonic) jets cruising in the high 30's, the difference between SAT (static air temperature) and TAT (total air temperature, SAT corrected for heat generated by the aircraft's skin) is usually around 25-30 degrees C. With a SAT at -60 you normally end up with a TAT around -30. FWIW.

We need to know more about shooting sub moa at 2400 fps. Gun, load, all of it.Maybe on a new thread.Please?joe b.

Attached Files

Frank;Here are some thoughts:We over emphasize the importance of BC/wind drift, a lot, at ranges to 200-300 yards.To increase BC = reduce wind drift we can change bullet design or velocity or density. That's all we can change.Your bullet, for example, at 1500 fps, would have wind drift reduced by half if the design changed and BC went to .6 or MV went from 1500 fps to 2400 fps. I suspect that getting rid of grease grooves and bands, and making the nose pointy = meplat smaller, would increase BC a lot, and easily. I know that increasing bullet length would increase BC, since, ceteris paribus, BC varies directly as length. For me, high CB velocities have not accompanied accuracy. All of which gets us to 31X299 or something close, but we've been there for many years. or

Attached Files

i suppose somebody somewhere knows what happens to soft point 224 bullets from at 220 swift at 4000 fps ... maybe hornady ? when i could see better, i think i saw glowing bullets at night from my pop-gun 222 at 3000 fps. but barrel heat ? not air friction ? interesting.

maybe if the points melt, the bc would change during flight ...oops .. too simple, as bullets do have different bc at different velocities ...

and, pushing out of my area of certainty ... one reason for a long sleek nose is to move the center of pressure back towards the center of gravity ... less ” leverage ” thus less moment to make the bullet wobble, thus higher bc from a less wobbling bullet.

it might be that for long ranges we would accept a less ” group-accurate ” bullet in exchange for a higher bc bullet ... the wind dispersion at 600 yards can be a lot more than group dispersion. here we see that the most * hit-accurate * bullet might not be the one that groups the best.

interestingly, this concept of actually HITTING something with our bullets ties into my ...rare but joyfull ...mentionment that average radius of dispersion ... should receive at least honorable mention along with the easy standard of the two widest shots.

i would guess that if lead bullets don't melt from barrel friction, they don't melt from air friction.

ken

Attached Files

Ken, One of the things that I'm trying to get at also, is the accumulation of heating (powder gas, barrel friction and the heating in the air), while it's unproven that the point will actually melt, it is a fact that heat will weaken a lead alloy. nose slumping could be a effect of that, although, I haven't seen slumping proven to my satisfaction. Of the three factors, the air has the longest time to work on a bullet, in the area of 1/3 sec for 2200 fps, opposed to mili sec for the other 2 factors. Also, we don't get the cooling effect of high attidude aircraft do and they don't reach those speeds at ~sea level.

Regarding jacketed 4000 fps loads in the Swift and the CHeetha, I remember reading that some of them discentagrated and was atributed to heat.

Frank

Attached Files

Joe,I'm not going to hijack Frank's thread, but I wrote a long thread about this shooting over on the NOE forum, with pictures. Gun, load, bullet, it's all there. I will start a new thread here on the CBA forum when I have more data to share.I wouldn't think it would be a problem for a skilled (and possibly also unskilled) machinist to chamfer a controlled radius on the nose meplat edge of , say, the NOE 310-165 FN (xcb) bullet. That would at least enable you to do a shooting comparison to determine if there's any performance and/or accuracy differences. I've been shooting this bullet sub-moa in the Mach 2.16 range recently, and it would be interesting to see if induced skin temperature indeed has an effect.

On regular (subsonic) jets cruising in the high 30's, the difference between SAT (static air temperature) and TAT (total air temperature, SAT corrected for heat generated by the aircraft's skin) is usually around 25-30 degrees C. With a SAT at -60 you normally end up with a TAT around -30. FWIW.

We need to know more about shooting sub moa at 2400 fps. Gun, load, all of it.Maybe on a new thread.Please?joe b.

Attached Files

i went to noe forum but can't find that post. timed out ? or do you have a link or copy ? thanks

Attached Files

Me too, bjornb. I don't have much time on the computer and don't want to be chasing over to other places. Thanks, Ric

Attached Files

Attached Files

"A longer point would give less head drag and thus less velocity loss in flight, but experience with long points in rifle cast bullets has shown that their failure to align the bullet reliably in heavy loads.”

E. H. HARRISON

This was his reason for the short point of the 311332 and 311334

Attached Files

"A longer point would give less head drag and thus less velocity loss in flight, but experience with long points in rifle cast bullets has shown that their failure to align the bullet reliably in heavy loads.”

E. H. HARRISON

This was his reason for the short point of the 311332 and 311334 That statement would apply to throating such as the '06 standard chambers. I've read most of Harrisons NRA works and I can not remember him doing any work with match type neck, freebores and long leades. Frank

Attached Files

Article “Paper Patch Comes OF Age” He test the Paper Patch 301618 up to 2750fps and the Paper Patch 301620 up to 2440 fps.

Attached Files

Frank;Here's some on alloy temp and strength etc, what happens as the bullet moves I'll send the EXCEL files if you want.joe b.

Attached Files

Although I never like the word “fiddling” connected to factual accounts. The following seems to agree with what I read regarding the measured temps recorded on the actual Concord flight readings as copied from your down load.

"Fiddling with the table of temperatures and velocities in the article, I find the formula to be: Delta T =: Temperature rise above ambient (Degrees F) = V^2(fps)/13310. Means that skin temperature equals velocity squared, divided by 13,310.Increases to T are: V (fps) Delta T 500 19 1000 75 1500 169 2000 300 2500 469 In the example of lead/1.5% antimony with a melting point of 600 degrees F, and an ambient temperature of 75 degrees F, the skin of a lead alloy bullet would become liquid at 2646 fps. The calculated skin temperature falls as bullet speed falls; and that's pretty fast. For example, a .202 BC bullet with 2700 fps mv has skin temperature of 548 degrees F above ambient at 50 yards; and 179 degrees F above ambient at 300 yards when v has fallen to 1545 fps. It seems unlikely that the center of the bullet reaches anything like the skin temperature."

The melting point of Linotype is given as 462-477F so, it would seem that thin, sharpe edges may be be prone to melting with just the air temp increase from muzzle velocity in the 2500 fps range.

I use that alloy because, that is what most sucessful Heavy and Unr shooters are using.

With regard to the friction and powder gas increases, I think that a real measurement will be required, such as a laser reading. I'm only guessing but, I think lead and lead alloys will have a higher thermoconductivity than steel and increase at a higher rate. Frank

Attached Files

Frank wrote: With regard to the friction and powder gas increases, I think that a real measurement will be required, such as a laser reading. I'm only guessing but, I think lead and lead alloys will have a higher thermoconductivity than steel and increase at a higher rate. Frank"

It apparently depends on what steel. For lead it is less than carbon steel but more than stainless. It seems to me that a lower conductivity would make the surface, the part of interest, heat faster. The heat couldn't dissipate as fast to cool the surface. But the time involved for dissipation is very short. Testing and numbers are needed.

John

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

John Carlson 22

-

linoww

17

linoww

17

-

Bud Hyett

14

Bud Hyett

14

-

drone 9

-

MP1886 7

-

beltfed 6

-

Lucky1 6

-

RicinYakima

5

RicinYakima

5

-

mashburn 4

-

beemer 4