Would you share your approach to routine mold maintenance. In a casting session yesterday I didn’t notice right away but I picked up some lead spalling that caused me to recycle 50 or so drops.

When I went to clean up I started to think about soldering irons or maybe Q tips and a bit of hydrogen peroxide/white vinegar etc. What’s ok to use and what isn’t ok to use.

Then I started to look at the top mold face and started to fret about permanent long term damage (I lube the top of the mold face about twice for every 100 drops. That caused me to grab two hands full of hair off my head and run around my shop screaming.

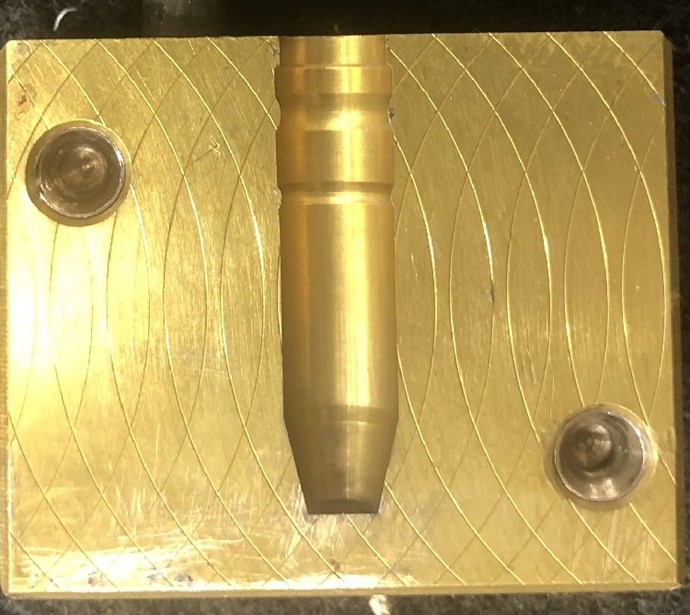

The more time I spend on cast accuracy the more I realize how valuable (Irreplaceable?) a mold that fits your bore is. This is brass but the same question would apply to iron and aluminum. Thanks, Bill C.

A “Measured Response” is as effective as tongue lashing a stuck door.