I've been casting bullets for over thirty years. Although I've tried many different recipes and lubes, I've settled on wheelweights, quenched in water, and tumble lube for my 230 gr. Lee TL bullets for .45 ACP. The combination works just fine, but as you all know, the tumble lube is a mess. So, I couldn't wait to try out powder coating once I heard about it. I read several things about it, including everything I could find on this forum. So, I took the leap. I bought a bottle of Heritage Freight black powder. I commandeered a butter bowl with the "triangle 5." I made some fresh bullets (just a couple of hours prior) and dumped them into the bowl with the powder coat. I shook, rolled, tumbled for about two minutes. All I got was a few clumps of coating stuck onto the bullets. Definitely nothing like an even coating. I didn't even waste my time trying to bake the coating. Next, I thought maybe the humidity was too high, so I brought all components into my home, where the temp is 72 and humidity is 32%. I let everything acclimate for 24 hours. I tried the shaking thing again. No luck. Nothing on the bullets but a few, black clumps. Next, I added several airsoft pellets. No difference. So, what gives? The bullets are not contaminated (they are right out of the mold), humidity is not too high, I'm using the right kind of bowl, I'm even adding airsoft pellets. No matter how long I shake, tumble, and rock and roll, I get nothing but a few clumps on the bullets. Help.

Powder coating failure

- 1K Views

- Last Post 30 April 2023

Harbor Freight paint will NOT work. The black is particularly bad. Sometimes the red will work. Sort of. Order some from Eastwood Automotive or Smoke4320 on the cast boolets forum. Stick with medium colors at first. Medium greens and reds seemed to work best for me.Sounds like your method should work. I degrease in acetone fresh out of the Moulds or not. Just in case.

Attached Files

First I tumble my cast bullets in sand. This gives the bullet a dull sand blasted appearance and helps the powder to grab hold.

Next i rense bullets well under hot water in a wire basket, dump bullets onto pan and then dry bullets in oven @200 degrees.

While bullets are slightly warm i apply the powder coating using plastic bowl and then dumping bullets into wire basket to get rid of excess powder.

Place bullets on non stick aluminum foil. I first wad up the foil into a ball , then i unravel the ball and lay flat on pan. The wrinkled surface of non stick aluminum foil works perfect and you will not need to stand bullets on base while baking. Just seperate the bullets so they are not touching each other before baking.

Eastwood Light Blue looks good. I have used Black with good results also.

Attached Files

My first experience, like yours, was dismal. I am sticking with a lubrasizer. It's less overall time and I like the smell of the lube burning off at firing.

With rifle in hand, I confidently go forth into the darkness.

Attached Files

Ordering some different powder was going to be my next step. I just did Harbor Freight because it is close-by.

Attached Files

I will order some new powder and will give your method a go. Never thought about the tumbling in sand, but that does make sense.

Attached Files

There are several powders that work well, and some that don't work at all.

Eastwood, Ford light blue is the easiest powder I've ever tried. Slightly pre-heating the bullets is helpful; you should still be able to touch them without discomfort, though. There is a little learning curve involved, but you'll get the hang of this!

Attached Files

I use a Lyman vibratory to tumble bullets. It only takes about 5 or 10 minutes to roughen surface. The sand (playsand) will be easy to dump out afterwards.

Rinsing bullets after tumbling also removes the static electricity. Static can repel powder coating.

Attached Files

One other thing to watch is the humidity. You are building up a static charge to coat the bullet. The lower the better. I tried HF black and it is just junk. The Eastwood Ford Blue works well.

As far as technique I have tried them all. The best way I have found is the way you are doing it with the BBs. I however add one step. I have some bins that are made to sort junk in drawers. They are just a fine mesh square screen. You could use a kitchen strainer but these flat ones are better for picking out the bullets.

Once you have agitated the bullets for a couple of minutes pour them into the bin. Put a cookie sheet under to catch the powder coat. Tap the bin a couple of times and all you should have left in the bin will be bullets and BBs. Sounds like a county and western band...Bullets and BBs. When you tap the bin you will shake off the excess PC which is giving you your lumpy coating. I use a pair of plastic tweezers that were in a first aid kit to pick out the bullets. There is a vendor on the "other" cast bullet forum who sells some good powders at a good price (smoke4320). I really like his John Deere green. Coats really well.

As far as baking goes I have found that you want to bake about 15 min. from the time the PC turns glossy. This works well for me and I PC everything from 223 up to 45-70.

Your Lee TL 45 will sit up just fine on your cookie sheet. When you start doing long tall skinny bullets you will need to invest in some silicon mini ice cube trays. Trying to put a sheet of 311-299s in the oven without support will make you want to hit the bottle.

Stay with it. I ended up giving all my 45-45-10 away and have never wanted to go back.

Attached Files

I have used Smoke 4320's John Deere green and Traffic purple with great coating success. I do not see the need for bb's. I simply put the as cast bullets into a number 5 container with the powder and agitate for about a minute and then I pour the coated bullets into a vegetable type steel mesh strainer and shake the excess powder off into the original container. I then pour the bullets from the strainer onto a piece of screen cloth that lines my baking pan. I then put them in a toaster oven that is at a measured 400 degrees and bake for 40 minutes.

It's my opinion that the screen cloth allows the melting powder to flow all around the bullet to then extent that you can barely see where the bullets contacted the screen. Sure is a lot easier than dabbling around with forceps or tweezers, etc.

Attached Files

Shuz,

I think I'm too close to the ocean. Without the BBs I just don't get a good coating. On dry days it will work without the BBs. I am curious as to what kind of screen you are using. I'm not sure what a "vegetable type steel mesh" is...I tried using pizza screens and could definitely see marks. I would love to toss my tweezers!

Attached Files

All very interesting guys. I ventured into powder coating about two weeks ago, borrowed an oven and bought some powder (Eastwood), I must say either I was lucky or did it right first time because my results have been very satisfying.

I haven't calibrated the oven, just wound the knob up to 200C and stuck them in for about 20 mins. I shake them around in a plastic ice-cream container and empty them onto a cake rack and then roll them onto some baking powder and in the oven.

I have given one and two coats a try, two looks better but does accuracy improve? depends on distance I would say.

I haven't seen any issue with outside temp or humidity, we are in the middle of summer at present so the day temp sits around mid to high 80's F and we are at 85-90% humidty with a cyclone forming up north, thinking of you Barra, batten the hatches.

Could they be better, probably, out of a pistol at 50yds does it matter a great deal, probably not.

When I get some time I will look at them for the 310 cadet and Rossi 357 but this was an exercise to see what the fuss is about.

All cast out of pure lead as they drop too big out of the Lee moulds and distort the projectiles too much after coating. No issues with leading at 1000fps and definitely not at lower velocities.

So here are some that I threw together on Monday.

Attached Files

Thanks for all of your inputs. This is what I mean when I say all I got was black clumps on my bullets. These have not been baked because I knew this coating was not going to work. This is using Harbor Freight black powder, a #5 plastic tub, airsoft pellets, and shaking. This is actually the third attempt. So, I will definitely be trying a different brand of powder.

Attached Files

A few things I have learned so far in my very limited experience with powder coating bullets. I only got involved in this for a friend who insists this is the greatest breakthrough in lead bullet technology ever, and my own curiosity!

- All powder coat materials are not the same and may require differing cure time and temperature.

- I tried two from Prismatic Powders, with greatly different degrees of success.

- Their Gloss Black, USS-2603, is described as a Urethane Solid Tone and behaved much like your results with Horror Freight black. Even two coats did not result in 100% coverage. Prismatic recommends curing for 10 min @ 400F.

- Their Astatic Red, PSS-1738 is described as a Polyester Solid Tone/Glaze and gave very consistent coverage. One coat was sufficient. Prismatic recommends curing for 12 min @ 400F.

- Before using either color, the bullets were cleaned in acetone.

All in all, this left me feeling as I was attempting to solve a problem that does not exist. I will experiment more, but have the feeling that I will be sticking with conventional lubes for all except 45 ACP bullets for my friend and 50 AE bullets for my Desert Eagle.

Wayne

Attached Files

Tumble lubing is easier than powder coating if you use the right lube. I suggest you Google “Ben’s Liquid Lube” and try that. A very light coat or two will work great. It is non sticky if done right. In my opinion you can’t beat it for pistol bullets at moderate velocity.

I powder coat my cast rifle bullets. Smoke4320’s Clear is very good, easy, and comparatively thin. It doesn’t add any color, obviously.

Rocky

Lifetime NRA since 1956, NRA Benefactor, USN Member, CBA Member

Attached Files

The vegetable strainer is just what can be bought at any place that sells kitchen utensils. The screen cloth is 1/4" mesh and can be bought at most hardware stores. Does this help.?

Attached Files

I also use Smoke4320's powder, black air soft BBs, and a clean CoolWhip container. Shake/swirl for 60secs, pick boolits out by hand while wearing latex gloves & shake to remove excess powder then lay on the toaster oven tray covered with non-stick (not regular) aluminum foil. Slide in and bake. Thanks to Shuz's tutelege my first attempt was a total success as has been every one since. ![]()

Have traffic purple, wine red, Carolina blue (Ford blue), black, and flame red, but have only used the traffic purple (which I think is more a certain kind of pink) so far.

Attached Files

When I started powder coating I used HF red and yellow. They both worked to a fair extent, but most bullets had to be coated and baked twice to get a good coating. I had already read not to use HF black or white. I then bought some from Smoke on castboolits, Traffic Purple and Carolina Blue. I don't have any pics but both of the powders I bought from Smoke adhered and covered beautifully. My advice is to get the higher quality powder coat and you'll get better results.

Attached Files

One pound of Smoke's traffic purple is a lifetime supply for me, and I shoot regularly. I thought about ordering a more manly color, but I'm too cheap and no one teases me at the club. ![]()

Only thing I can add is to put the powder into a bottle. That way you can easily add just the right amount to your butter dish and not have to deal with shaking off the excess.

Attached Files

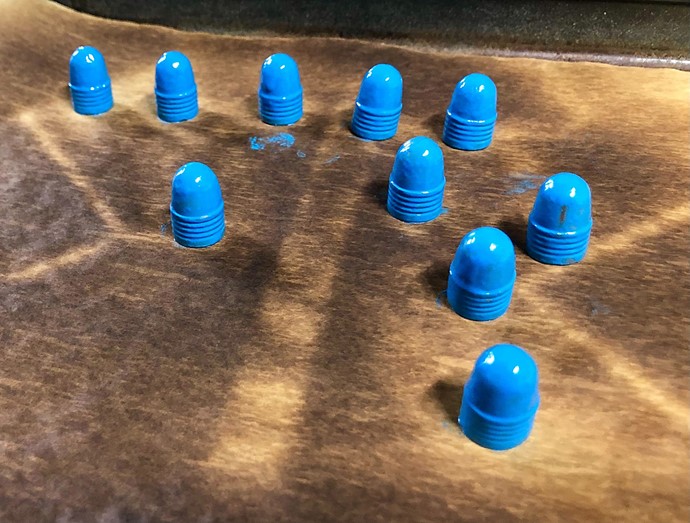

Well, I have read all your suggestions closely. I thank you for all your comments, they have been very helpful. I ordered some Eastwood Ford Blue. I shook in a #5 bowl for one minute, with Airsoft BBs. The powder was still a little spotty, but much better than the HF Black. I baked at 400 degrees for twenty minutes after the powder melted. I am much, much happier with the result. Not perfect, but at least now I am on the right track. I loaded up about twenty of these today and fired in my Kimber .45. They worked flawlessly, no leading, residue cleaned up easily, and accuracy was good. Again, I appreciate all the help. Here is a photo of the results:

Attached Files

WOW! Some of you guys are going way to far into doing this. You don't need to sand blast it sticks perfectly fine to a glass smooth bullet. You don't need the bb's. You don't need to wash in acetone unless they are contaminated with something.

Spin the bullets in the container on the inside wall off the container. Shaking them so they spin all the way around is the key. Then dump them out into a colander and shake them around to get the excess powder off the bullets. Then dump them into a tray. This is as far as you have to take it. Sand blasting them is a complete waste of time. If it was an oil then it would help the oil to stick. Powder coat relies on static and that only to stick. Unless you are hot flocking then the part is heated up first then the powder is sprayed on.

Attached Files

I agree that it is a simple theory, but not so simple in practice (not for me, anyway). However, I was very happy with the last batch. I've learned a couple of things: 1) Don't use HF powder; 2) I had better luck when I used the BBs. This makes sense. The BBs are plastic and swirling them around with the bullets should, in theory, cause a greater static charge; 3) If you try the vibratory tumbler method, make SURE the tumbler top is securely fastened! I'd read where some folks did this with good results. I thought I'd give it a go, since I have a tumbler. I dropped bullets and powder into tumbler, turned it on, set my timer for twenty minutes and left the building. I came back in twenty minutes and everything within twenty feet had a nice, light-blue color. Seems the top of the tumbler had vibrated off and powder went everywhere!; 4) I think one of the reasons people get such different results (and have to resort to other methods to help adhesion) is atmospheric. A static charge will not build up on a warm, humid day in Alabama the same way it will on a cool, dry day in Montana. So, what works for one guy may not work so good for another.

Attached Files

What ever you do DO NOT tumble your bullets in sand. Unless you want to shoot out the barrel very fast. But at least it will be shinny from sanding it.

Attached Files

So how many coats is best? Has anyone done any major testing on accuracy at 50, 100yds etc. Is it just a purely cosmetic effect, if it looks perty, it must be better? I haven't found any comparison with leading effect between one and two coats, just means I need to size the projectile again after that second coat.

And the next question, have you changed your alloy mixture to accommodate the increase in diam after coating. I am trying pure lead only otherwise my sizes are all over the shop.

Tony

Attached Files

Not to revive an older thread but I tried Harbor Freight red and yellow when I started powder coating. Each covered fairly well, and much better with a second coat. Then I bought some of smokes Traffic Purple and Carolina Blue and all my troubles were gone. I agree that the HF Black is not worth using. I tried finding some screen small enough and it was a bust, so I still use my tweezers. I tried alox lube and I'll stay with powder coating.

Attached Files

If Harbor Freight worked at all for you, then you are indeed fortunate. My first go was with HF red. Total crap. So I tried using the HF static gun. Not only was it still total crap, but everything within 3-4 feet was covered in red dust. Now using Eastwood and pistol bullets are tolerable, but rifle bullets still can't compare to conventional sized and lubed for accuracy.

Not only was HF powder a disaster, my first time I did not check the oven with a thermometer -- slagged them all.

After determining that the temp settings on the toaster oven were a guesstimate, I slagged a couple more batches until I learned that if you don't pre-heat the toaster oven it will overshoot the temp. All slagging events would probably not have happened had I not been using rifle bullets cast of linotype.

For some reason I was not a believer in powder coating until the HF and temp problems were ironed out ........![]()

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

Aaron

25

Aaron

25

-

jeff houck

20

jeff houck

20

-

Tom Acheson

17

Tom Acheson

17

-

Wilderness

14

Wilderness

14

-

John Carlson 13

-

sghart3578 10

-

MarkinEllensburg

10

MarkinEllensburg

10

-

Spindrift

5

Spindrift

5

-

alphabrass

5

alphabrass

5

-

SkinnerD 5