Hi there guys! I have a friend that is one of those folks that comes up with the greatest things out of the blue... Thankfully he is as involved with firearms as least as much as all of us, and a crackerjack gunsmith to boot.

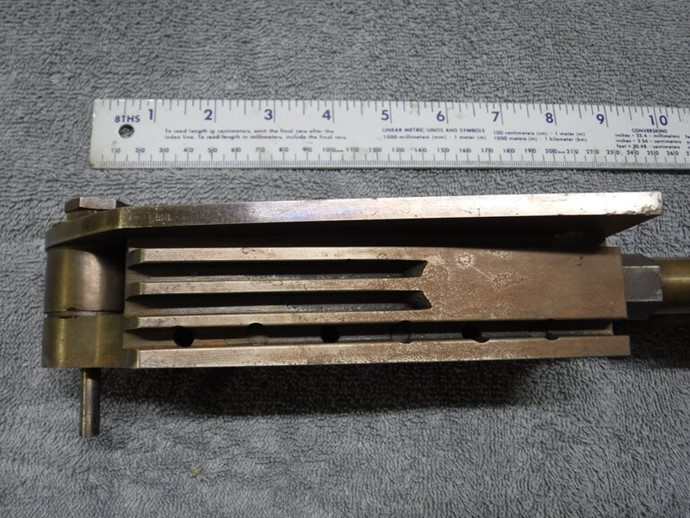

Anyway, he recently walked into my shop, and handed me the pictured mould. "Check THIS PUPPY out", he said. The pictures are worth 1000 words, but suffice it to say this mould is huge, and it's heavy. It bears no identifying marks whatsoever, and I was hoping that someone here in the "brain trust" may have an idea as to who the maker might be, and any additional info or history involved with it. I'm very curious!

I cast a few drops with it (after screwing the handles off and pre-heating it to max in the toaster oven..still took a few pours to get the beast up to workiing temp!) just to see what it produces. I had some fairly hard alloy (3/4 old WW, 1/4 Lino) already in the pot, so that's what I used. Bullets dropped effortlessly out of all 8 cavities.

The slugs produced are right at .360", and weigh 155 gr. with this alloy... Obviously would probably use a softer alloy casting for .38 Special, etc., but as I said, that's what I had in the pot at the time.

The machine work on this mould is superb... A heavy-duty example of what I would imagine is old time craftsmanship.

Any ideas?