Wm Cook

posted this

18 September 2023

Mark everything is with Linotype at this time and I ran a constant 695 on this last batch. I really new to this so you have to take what I say with some room for misinterpretation.

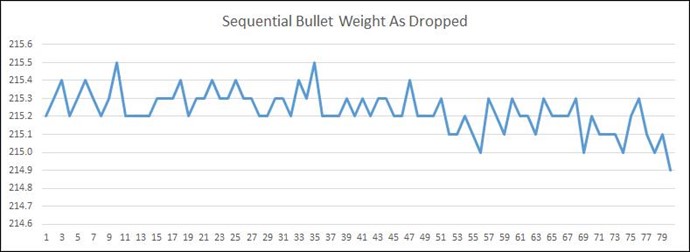

I've been trying to cast consistent bullets since last year. Last May I had two casting sessions in one day. In the AM they dropped around 214.7 and in the afternoon they dropped around 215.8. To make a long story short I found was that a change to the mold temperature effects the drop weights to a greater degree than a change of alloy temperature. Alloy temperature being more forgivable to its effect on bullet weights and mold temperatures having a greater impact on drop weight.

If I cast at 660 the alloy viscosity seems to thicken and negatively effects a clean pour into the mold and requires more frequent fluxing. In my mind 670 would be the lowest I could go. At 715 the alloy seems to be almost too hot and a dark contamination occurs on the alloy surface. Like a dark bronze.

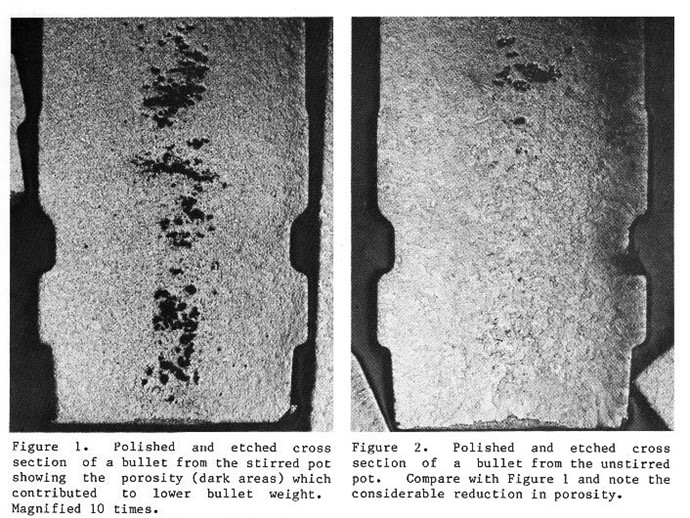

I flux by giving the pot a long stir (60 sec) while I scrape the sides/bottom and gathering everthing together to the top. I then add a couple, three pea size pieces of clean wax and let it burn for a bit. Then while burning I stir it into the pot and keep working the buildup on the surfice back into the pot. At the end if I see tin still in the dross I repeat to get it to separate. Eventually I wind up with a table spoon or two of dark grey matter that skims off and leaves a clean surface. Best bet is that what I scoop off is almost a dry powder, not a chunk. The first 20 to 30 drops after fluxing are a dream. Clean fluid pour out of the ladle spout and a pleasant pour into the cavity. If I get off my dead rear end and put that old bottom pour Lyman Mag 20 together I'd have a second bottom pour so I could compare the two.

I think you may be right about the ladle carrying the contaminents into the alloy. By stirring the pot between each pour I can extend the number of drops I get between fluxing but I frequently rap the ladle on the top edge of the pot to knock off buildup of contaminents. My Lyman ladle is probably 30+ years old. I have to others; Lee and the Roto Metal. The Lee is too small for most anything and the RotoMetal is a great design but won't fit in my 10lb pot.

Again, if I get off my dead butt and modify that Lee bottom pour furnace that I shelved into a ladle desigh maybe I could use the larger ladle.

Sound like I'm the problem doesn't it. Thanks for helping. Bill.

A “Measured Response” is as effective as tongue lashing a stuck door.