I have been shooting a NOE pattern bullet in my .257 Roberts AI. The mold belongs to a friend who bought it as part of one of the early group buys that Al at NOE did. The mold throws a plain base 90gr bullet and a 120gr GC version.

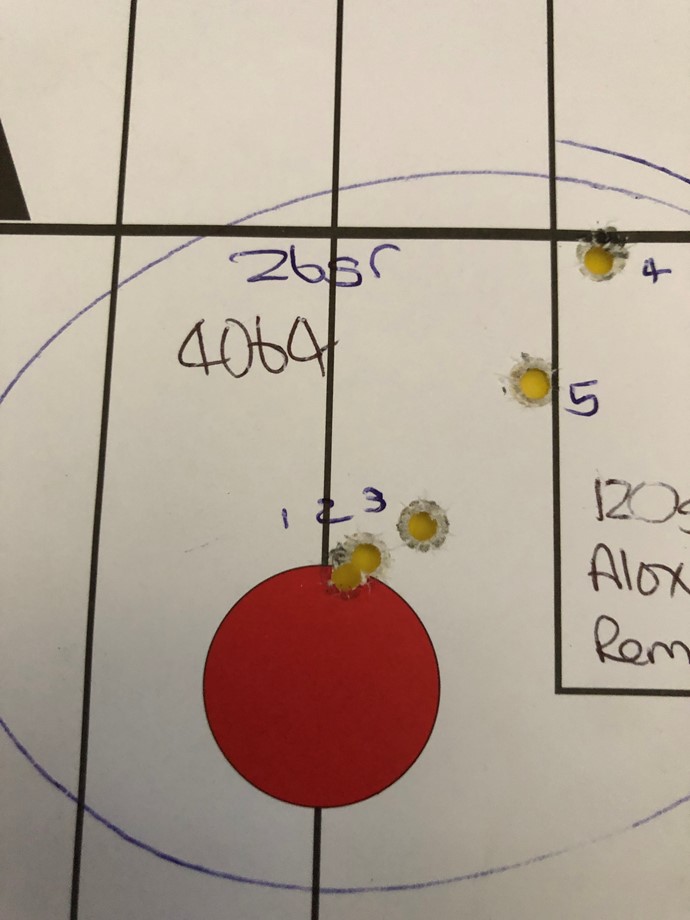

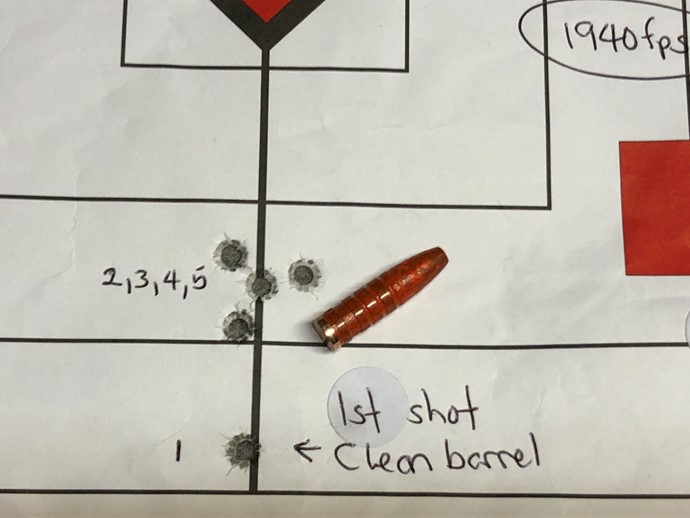

The GC version is rather inconsistent. I have been casting in ACWW and burning numerous powders under it. Some groups will be very good and others will 1) throw a couple of rounds out of the group and/or 2) produce oval holes indicating tipping. This is happening with PC and lubed bullets.

I wonder if the bullet is collapsing due to the wider lube groove created by lengthening the bullet from 90 to 120gr.

Thoughts?

Cheers from New Zealand

.jpg?width=690&upscale=false)

.jpg?width=690&upscale=false)

.jpg?width=690&upscale=false)