If you've been following my 6BR thread you may be aware that I ran into some issues using smaller diameter indenters to measure BHN with my homemade tester, so I'm going back to the drawing board. First up, my original 10mm indenter had been turned on a lathe, and while the lathe did a pretty darned good job, there were some microscopic imperfections on the tip of the indenter. The imperfections don't show in this photo so you'll have to take my word for it. Anyway, I splurged on some 10mm ball bearings and epoxied a ball bearing into a 5/8” thingamajiggy that fits into my push-thru die holder.  I used to measure the indentations with calipers and a magnifier, but then someone pointed out that Gimp (and some other free photo editing programs) have a “measure” tool. Take a photo of the indentation with some sort of scale in the picture, then you can zoom in on the photo and measure the indentation with accuracy limited only by the resolution of the photo. A USB microscope works well for taking the photo, but some cameras and even phone cameras are capable of taking decent closeups.

I used to measure the indentations with calipers and a magnifier, but then someone pointed out that Gimp (and some other free photo editing programs) have a “measure” tool. Take a photo of the indentation with some sort of scale in the picture, then you can zoom in on the photo and measure the indentation with accuracy limited only by the resolution of the photo. A USB microscope works well for taking the photo, but some cameras and even phone cameras are capable of taking decent closeups. Load the photo in Gimp. Measure the scale (this one is marked in tenths of an inch). In this example, the measurement across 0.300” on the scale was 569 pixels. In other words, the scale of the photo is 569 pixels per 0.300 inch, or 1897 pixels per inch. Next I measured the diameter of the indentation. I actually measured in several different places: 257 pixels, 257 pixels, 261 pixels. Well, the cat was chewing on my arm when I took the last measurement!

Load the photo in Gimp. Measure the scale (this one is marked in tenths of an inch). In this example, the measurement across 0.300” on the scale was 569 pixels. In other words, the scale of the photo is 569 pixels per 0.300 inch, or 1897 pixels per inch. Next I measured the diameter of the indentation. I actually measured in several different places: 257 pixels, 257 pixels, 261 pixels. Well, the cat was chewing on my arm when I took the last measurement! ![]() Average of the three measurements = 258 pixels. To convert that to inches, divide 258 pixels by 1897 pixels per inch, = 0.13618 inch.

Average of the three measurements = 258 pixels. To convert that to inches, divide 258 pixels by 1897 pixels per inch, = 0.13618 inch.  The applied load was 150 kg. for 30 seconds -- more on how I apply the load later. Plug the numbers into the formula for BHN (a spreadsheet crunches the numbers for me) and we get 15.6 BHN. Should we believe that number? Well, the alloy was 50% lino and 50% clip-on wheelweight, and I was expecting 16 BHN. That's pretty close.

The applied load was 150 kg. for 30 seconds -- more on how I apply the load later. Plug the numbers into the formula for BHN (a spreadsheet crunches the numbers for me) and we get 15.6 BHN. Should we believe that number? Well, the alloy was 50% lino and 50% clip-on wheelweight, and I was expecting 16 BHN. That's pretty close. ![]() In the next few days I'll try to post measurements for all my alloys including “known” standards like pure lead and linotype. Then I'll repeat the tests with different indenters and different loads and see how the results stack up. Most people buy store-bought BHN testers and that's fine, but like many casters I enjoy making my own stuff whenever possible. I'm not going to run out and buy a store-bought tester, but if anyone wants to loan me their store-bought tester, I'll be glad to include it in my comparisons.

In the next few days I'll try to post measurements for all my alloys including “known” standards like pure lead and linotype. Then I'll repeat the tests with different indenters and different loads and see how the results stack up. Most people buy store-bought BHN testers and that's fine, but like many casters I enjoy making my own stuff whenever possible. I'm not going to run out and buy a store-bought tester, but if anyone wants to loan me their store-bought tester, I'll be glad to include it in my comparisons.

BHN Measurement Revisited

- 4.7K Views

- Last Post 07 August 2016

Attached Files

My favorite ball bearing company in the world is right in my neighborhood will have just the bearing for you:

They specify the smoothness of their bearings in microns, and they mean it.

Gary

Attached Files

The accuracy of measuring about anything varies with the a number of measurements. The ratio of measured value/true value varies with the number of measurements made. One measurement, group size or BHN or MV, tells us little. Somewhere around 5 measurements the ratio starts getting smaller, 10 is better, 30 is sorta the recommended minimum.

This, the data, illustrates the principle:

joe b.

Attached Files

Thanks for the link, Joe. Lots of good data there.

Just to address your point, I'll repeat the 10mm test on 50/50 alloy 10 times. My guess is that there will be negligible variation with my tester as long as I use the same indenter and the same load, but we'll see.

In real life few of us are going to measure 30 different bullets and take an average, so if a test does not give an accurate result on the first try, what good is it?

Part of the variation in Shay's test is due to using many different testers. For example, 13 different Cabine Tree testers were used. For any one Cabine Tree tester, the standard deviation was very low, averaging 0.5 BHN. But ... the Cabine Tree averaged 4.3 BHN harder than a lab BHN test -- that would be a problem for me.

If you are only using BHN measurement for your personal use, then I suppose it doesn't matter whether your test result is 4.3 BHN off, as long as it is consistent (and some of the test results in Shay's test were not consistent). But if you are reporting your BHN test results to the public, as I often do, then I want it to be right, so that the public can believe what I say.

Shay's test only tested the one alloy. My intention is to test the full range, from pure lead up to linotype, and also hardened bullets. Is the tester accurate over the full range?

One goal in this test is to see if different sizes of indenters and different loads give the same BHN result as the standard 10 mm indenter and a standard load (typically 100 kg, 500 kg, or 3000 kg). As noted in my 6BR thread, it appears that smaller indenters result in erroneously high BHN's. Most of the testers in Shay's article also gave high BHN's, so apparently I was not imagining things.

Assuming it turns out that the smaller indenters give high BHN's, a second goal will be to see if it is possible to come up with a correction factor to adjust the result.

Gary, it's good to know that a few bearings are still made in America. :)

Attached Files

a depressing result of mr. mtn's testing is that the formula for sampling BN doesn't appear to work . dangit !!

i made a excel ( ok, open office ) spreadsheet to follow along with the frustration ...if anybody wants a copy pm me with your email . plug in the numbers in kg and mm , just like the formula calls for. mtn did the math right...the results did vary from the formula.

?? story of my life ... heh

ken

Attached Files

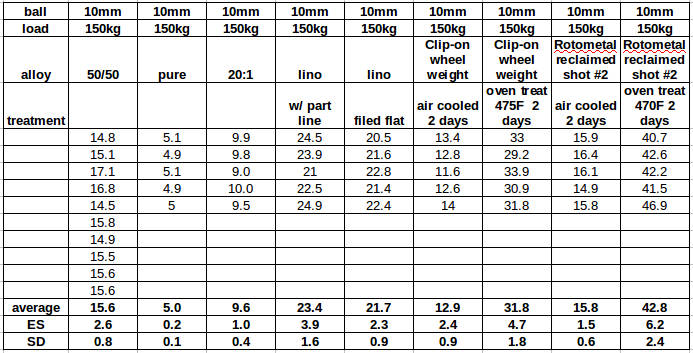

As per Joe's suggestion I measured 9 more of the 50% lino / 50% COWW bullets, using 10mm/150 kg, so now there are 10 data points for that combination.

BHN's: 14.8, 15.1, 17.1, 16.8, 14.5, 15.8, 14.9, 15.5, 15.6, 15.6

AVERAGE: 15.6

E.S.: 2.6

S.D.: 0.84

Attached Files

I have a Cabin Tree tester, and that is about my spread. It can vary 2 BHn within one ingot. FWIW, Ric

Attached Files

Ric, I admire the design of the Cabin Tree tester. The Lee appears to be a decent design, too, though perhaps challenging to read its itty bitty indentation. Lee users might benefit from using digital photo measurement. More data using the 10mm ball bearing and a 150 kg load. The first set of linotype measurements were made without filing the part line off the bullets -- and the mold that I use to cast the 45 caliber cylindrical test slugs does have a distinctive part line. Well, the part line seemed to cause a lot of variation on the high side, so I filed off the part line and tried again, and got much better results. In general it is looking like the homemade tester does a bang-up job as long as I use a 10mm indenter and as long as I file the part line off hard bullets.  The tentative plan is to collect a bunch of data with both the 10mm ball bearing and with a 4mm ball bearing, and then see if I can come up with a correction factor for the 4mm results.

The tentative plan is to collect a bunch of data with both the 10mm ball bearing and with a 4mm ball bearing, and then see if I can come up with a correction factor for the 4mm results.

Attached Files

Yep, the only real issue I have with the Cabin Tree is that the back has to be flat also, otherwise it rocks and screws up the measurement. There is a learning curve to make this tooling work.

Attached Files

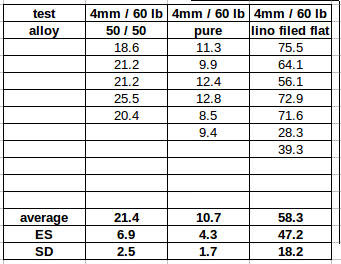

One of the goals of this project was to try to find a way to get decent results with a 4mm ball, so that I'd have a way to measure 22 & 243 caliber bullets. Also I wanted to try a 4mm / 60 pound combination because I read somewhere that the Lee tester uses 4mm / 60 pounds (actually 5/32” but that's nearly the same as 4mm). Here's some results for 4mm / 60 pounds, and as you can see, they stunk. Not only were the BHN's goofy, but the variation was awful. I.e. linotype measured anywhere from 28.3 BHN to 75.5 BHN. :X I've never used a Lee hardness tester so I can't comment on how well it works, or if it really uses 5/32” / 60 pounds. If anyone wants to mail me their Lee tester on loan for a week or two I'll be glad to run it through its paces.  So then I tried increasing the weight on the 4mm ball to 50.3 kg (111 pounds). No joy, it still gave nonsense numbers with lots of variation.

So then I tried increasing the weight on the 4mm ball to 50.3 kg (111 pounds). No joy, it still gave nonsense numbers with lots of variation. ![]()

Again I increased the weight on the 4mm ball, this time to 71.8 kg (158 pounds), but the BHN numbers were still nonsense.

Again I increased the weight on the 4mm ball, this time to 71.8 kg (158 pounds), but the BHN numbers were still nonsense. ![]()

Maybe I'm missing something, but I haven't been able to get a 4mm test to work decently. I'm going to give up on 4mm for the time being.

Maybe I'm missing something, but I haven't been able to get a 4mm test to work decently. I'm going to give up on 4mm for the time being. ![]() Continued in the next post ...

Continued in the next post ...

Attached Files

From “Engineering Properties and Applications of Lead Alloys” by Sivaraman Guruswamy:The takeaway is that his recommendation for measuring the BHN of lead alloys is 10mmm / 125 kg for 3 - 39 BHN, or 10mm / 250 kg for 5.6 - 78.8 BHN.

Attached Files

The good news is that I continue to get decent results using a 10mm ball bearing and 150 kg load. The numbers for known alloys like pure lead and linotype look good, and the other alloys are at least in the ballpark. Repeatability is fair. One thing I learned while doing these tests is that imperfections on the the surface of the bullet can affect the results quite a bit. I got into the habit of filing the surface to remove any part line and to make the surface reasonably flat, but the file leaves microscopic striations and even a filed surface sometimes is still not flat. Striations or non-flatness seem to result in BHN variation on the high side. FYI “R2RS” = Batch #2 of Rotometals Reclaimed Shot, and “HTR2RS” = Oven Treated Batch #2 Rotometals Reclaimed Shot.  I've been experimenting with different webcam software to operate my cheap USB microscope (in Linux). For this photo I used “Cheese", with the resolution set at 1600 pixels wide. That gives you some respectable resolution for measuring even small indentations like on this heat treated reclaimed shot.

I've been experimenting with different webcam software to operate my cheap USB microscope (in Linux). For this photo I used “Cheese", with the resolution set at 1600 pixels wide. That gives you some respectable resolution for measuring even small indentations like on this heat treated reclaimed shot. ![]()

Another thing I noticed is that if I measured a particular indentation with digital photo measurement, and then checked the measurement with calipers under a magnifying lamp, the calipers would always read 0.003” - 0.009” larger. Which is the correct measurement? I'm not sure, but I'm going to stick with digital photo measurement rather than relying on my not-so-good eyesight to read calipers.

Another thing I noticed is that if I measured a particular indentation with digital photo measurement, and then checked the measurement with calipers under a magnifying lamp, the calipers would always read 0.003” - 0.009” larger. Which is the correct measurement? I'm not sure, but I'm going to stick with digital photo measurement rather than relying on my not-so-good eyesight to read calipers. ![]()

![]()

![]() A customer kindly offered to loan me his Cabin Tree tester for this evaluation, and when it shows up I'll run it through its paces and see how it compares to my homemade tester. Otherwise, my plan is to stick with the 10mm / 150 kg homemade tester. That means I will not be able to test small caliber bullets, but oh well.

A customer kindly offered to loan me his Cabin Tree tester for this evaluation, and when it shows up I'll run it through its paces and see how it compares to my homemade tester. Otherwise, my plan is to stick with the 10mm / 150 kg homemade tester. That means I will not be able to test small caliber bullets, but oh well. ![]() I'm thinking about making another homemade tester, based on a nutcracker design, that will have more leverage so it can use 200 - 300 kg load, for a bigger indentation on heat treated alloys.

I'm thinking about making another homemade tester, based on a nutcracker design, that will have more leverage so it can use 200 - 300 kg load, for a bigger indentation on heat treated alloys.

Attached Files

I have a lee tester and would be glad to put it in the mail to you if someone else hasn't already offered and your offer is still open. Same with my LBT tester that I believe you asked for earlier. I have used the LBt tester for a long time and when I use it on Linotype or Lyman #2 it seems to give reasonable results although you have to use carefully and take several readings.

John

Attached Files

I added 20:1 alloy to the chart for the homemade tester with 10mm ball & 150 kg load. Most sources put 20:1 at 10 BHN, and my homemade tester averaged 9.6 BHN.  It looks I'll be getting the loan of John's Lee hardness tester (if he can find it!

It looks I'll be getting the loan of John's Lee hardness tester (if he can find it! ![]() ) so it'll be interesting to see if Lee has better luck with a 4mm ball than I did.

) so it'll be interesting to see if Lee has better luck with a 4mm ball than I did.

Attached Files

Can you compare your results to the process that I use?

I first got it out of the old NRA Cast Bullet publication.

"pure lead diameter / sample diameter, squared, times 5"

I have always used a 5/8” diameter ball, on igots and was able to get accurate measurements when compared to BHN harness.

I use a arbor press to make the indent but, as pressure doesn't seem important with this medthod, a lot of people use a vise. I haven't tested other size balls but, it's not suppose to be important either.

Frank

Attached Files

Can you compare your results to the process that I use?

I first got it out of the old NRA Cast Bullet publication.

"pure lead diameter / sample diameter, squared, times 5"

I have always used a 5/8” diameter ball, on igots and was able to get accurate measurements when compared to BHN harness.

I use a arbor press to make the indent but, as pressure doesn't seem important with this medthod, a lot of people use a vise. I haven't tested other size balls but, it's not suppose to be important either.

FrankMy 10mm / 150 kg indentation for pure lead = 0.232" My 10mm / 150 kg indentation for oven treated reclaimed shot = 0.083"

Plugging those numbers into your suggested formula yields 39 BHN for the oven treated reclaimed shot, vs. 42.6 BHN using the standard equation for BHN. So your process appears to produce reasonable results as long as a 10mm ball is used. I have not tried a 5/8” ball.

Attached Files

In thousands of a inch, the error for the HT alloy would only be .0035 (.0795 Vs .083) to make the formula read 42.6.

I'm a retired machinist of 40+ years and I use a dial caliper with a 5X, magnetic loupe attached to it. Even with that, it's hard to define the exact edge of the indent.

Although not available to most anyone (I don't even have one) the best way to measure the indent is with a 20X Comparator.

Frank

Attached Files

Agree, Frank.

The biggest disadvantage I see to the ingots-in-a-vise method is 1) it would be tough to do with individual bullets and 2) ingots usually have a rough surface, or at least my ingots do. Plus I would encourage anyone using it to use a 10mm ball. I paid $8 for 100 ball bearings so that's still a bargain compared to a store-bought tester.

My interest in BHN has always centered around heat treating or age hardening of antimonial alloys, so I want to be able to measure bullets, not just ingots.

I've finished the Cabine Tree tests -- they went very fast because it was very easy to use -- and will try to write up the results later this evening.

John offered the loan of his LBT tester, but I'd already used one back in the mid 80's and already formed an opinion, so I'm not planning to include the LBT in this comparison. The shorter version is that I thought there was a lot of variation and that I could make a better tester myself, hence my homemade tester. On the plus side, the LBT is capable of measuring small meplats and seems to give a result that is at least in the ballpark, which is more than you can say for some testers. :D

Attached Files

The borrowed Cabine Tree tester showed up. I was impressed with the heft and the quality. ![]()

The Cabine Tree does not use a ball indenter, rather it uses a cone with a small meplat. Similar to a Saeco tester, it doesn't really read BHN, it just reads “something” and that “something” is supposed to correlate to BHN.

The Cabine Tree does not use a ball indenter, rather it uses a cone with a small meplat. Similar to a Saeco tester, it doesn't really read BHN, it just reads “something” and that “something” is supposed to correlate to BHN.  It was extremely easy to use the Cabine Tree and the tests went very quickly. The dial indicator eliminates most of the human error. The instructions suggested filing a flat on the surface to be measured, and I agree with that. I also found it helpful to lightly file the other end of the bullet, to knock off the sprue bump. If you don't, the sprue bump might compress a little bit during the test, and that will throw the reading off. A supplied chart is supposed to correlate the dial indicator results to BHN

It was extremely easy to use the Cabine Tree and the tests went very quickly. The dial indicator eliminates most of the human error. The instructions suggested filing a flat on the surface to be measured, and I agree with that. I also found it helpful to lightly file the other end of the bullet, to knock off the sprue bump. If you don't, the sprue bump might compress a little bit during the test, and that will throw the reading off. A supplied chart is supposed to correlate the dial indicator results to BHN  I measured each alloy at least 5 times and took an average, results below.

I measured each alloy at least 5 times and took an average, results below.  I had high hopes for the Cabine Tree because it looked well built -- and it is well built -- and because the dial indicator removes most of the human error. But like most storebought hardness testers, the Cabine Tree uses a small indenter rather than the standard 10mm ball. That's understandable because a 10mm Brinell tester would be big and heavy and expensive. The problem is that it seems to be difficult to get good results with a small indenter.

I had high hopes for the Cabine Tree because it looked well built -- and it is well built -- and because the dial indicator removes most of the human error. But like most storebought hardness testers, the Cabine Tree uses a small indenter rather than the standard 10mm ball. That's understandable because a 10mm Brinell tester would be big and heavy and expensive. The problem is that it seems to be difficult to get good results with a small indenter. ![]()

Attached Files

Following up on Frnkeore's suggestion:

My first thought was “But that only works on ingots. How would you use it to measure bullets?"

This is what I came up with.

I use a 45 caliber cylindrical slug for BHN and density measurements. In any event, 45 is a popular caliber so many casters will have a mold for a flat nose 45.

I cut a piece of 1/2” pex pipe that was slightly shorter than 2 cylinders and the 10mm ball. The pex serves to hold the cylinder sandwich together during the test. Put the sandwich in a vise and squash them.

That was easy! :) However, the pure lead slug obturated so much that it was stuck inside the pex. :( To get it out, I ended up slitting the pex with a utility knife. That's OK, the slitted pex still will serve to hold the cylinder sandwich.

Results, as measured with a USB microscope: Dpure = 0.299" Dlino = 0.1535"

5 BHN * (Dpure / Dlino)^2 = 19.2 BHN

That compares to 21.7 BHN for the 10mm / 150 kg test. At least it's in the ballpark.

I'll run this system through its paces with other alloys and we'll see if it continues to give ballpark accuracy.

Advantages: -- cheap, cheap, cheap ! -- if it indeed gives reliable ballpark accuracy, that's more than you can say about some hardness testers. :D

Attached Files

Following up on “Frnkeore's Method” aka the “cylinder sandwich", here are the results. Besides linotype, I included one medium-hard alloy and one extra-hard alloy for the test so that the full spectrum of BHN would be covered. Since the hardness of COWW and reclaimed shot are age-dependent, I retested a single sample of each on my homemade 10mm / 150kg tester. The 6-day old air cooled wheelweight was 15.3 BHN, and the 6-day old oven treated reclaimed shot was 42.7 BHN.  I thought the accuracy of the “cylinder sandwich” was decent -- better than some storebought testers -- providing you take an average of several measurements, providing the pure lead that you use for comparison is really pure lead (my pure lead was store bought and supposedly 99.99% pure, or something like that), and providing you have a way to measure the indentations accurately. Considering that it only costs $8, the “cylinder sandwich” is a viable alternative to store bought BHN testers.

I thought the accuracy of the “cylinder sandwich” was decent -- better than some storebought testers -- providing you take an average of several measurements, providing the pure lead that you use for comparison is really pure lead (my pure lead was store bought and supposedly 99.99% pure, or something like that), and providing you have a way to measure the indentations accurately. Considering that it only costs $8, the “cylinder sandwich” is a viable alternative to store bought BHN testers.

Attached Files

I think if you make a short sleeve, to center the ball, inside of the tubing, the ES will come down on the harder alloys.

As I remember, the NRA article said that you could use the ball on the edge of a ingot and that both ingots had to be at least 1/2” thick. I'll try to find it.

Frank

Attached Files

I received the loan of a new toy -- er, I mean tool -- to play with. ![]() The Lee tester uses a spring loaded 5/32” ball. According to my calculations, the spring exerts 59.2 pounds force on the ball when compressed as per the instructions. That's pretty darned close to Lee's claim of 60 pounds. :cool:

The Lee tester uses a spring loaded 5/32” ball. According to my calculations, the spring exerts 59.2 pounds force on the ball when compressed as per the instructions. That's pretty darned close to Lee's claim of 60 pounds. :cool: To my surprise, the 20X graduated pocket microscope included with the Lee tester was of decent quality. The scale shows up clearly in the scope, and when I held the Lee scope up to a stainless steel scale, they matched up within 0.002” over 0.100". My only complaint about the pocket microscope is that it shows you a mirror image, so if the view shows that the scale is to the right of the indentation, it's actually to the left. This is confusing when you are trying to get the scale lined up with the indentation. But .... I've already tested a 4mm ball (nearly the same as 5/32") and a 60 pound load on my homemade BHN tester, and the results were goofy. Can the Lee tester somehow do a better job than my homemade 4mm / 60 pound test? The Lee tester leaves itty bitty indentations on hard alloys. Nonetheless, the pocket scope is accurate enough to measure them, though it can be difficult to maneuver the pocket scope to get the scale lined up with the indentation. After satisfying myself that the pocket scope gave good readings if you tried hard enough, I switched to using the USB microscope. The USB microscope & digital measurement in GIMP gave the same measurements as the pocket scope, but it was much much easier to use the USB microscope.

To my surprise, the 20X graduated pocket microscope included with the Lee tester was of decent quality. The scale shows up clearly in the scope, and when I held the Lee scope up to a stainless steel scale, they matched up within 0.002” over 0.100". My only complaint about the pocket microscope is that it shows you a mirror image, so if the view shows that the scale is to the right of the indentation, it's actually to the left. This is confusing when you are trying to get the scale lined up with the indentation. But .... I've already tested a 4mm ball (nearly the same as 5/32") and a 60 pound load on my homemade BHN tester, and the results were goofy. Can the Lee tester somehow do a better job than my homemade 4mm / 60 pound test? The Lee tester leaves itty bitty indentations on hard alloys. Nonetheless, the pocket scope is accurate enough to measure them, though it can be difficult to maneuver the pocket scope to get the scale lined up with the indentation. After satisfying myself that the pocket scope gave good readings if you tried hard enough, I switched to using the USB microscope. The USB microscope & digital measurement in GIMP gave the same measurements as the pocket scope, but it was much much easier to use the USB microscope.  To my surprise, the Lee test results were mostly in the ballpark and the variation from measurement to measurement was reasonable.

To my surprise, the Lee test results were mostly in the ballpark and the variation from measurement to measurement was reasonable.  I have more to say about why the Lee gave good results while my homemade 4mm / 60 pounds test gave bad results, but it's been a long day so that will have to wait until tomorrow. In the meantime I give the Lee hardness tester good marks, though you'll probably struggle with the pocket microscope. Use of digital measurement is highly recommended.

I have more to say about why the Lee gave good results while my homemade 4mm / 60 pounds test gave bad results, but it's been a long day so that will have to wait until tomorrow. In the meantime I give the Lee hardness tester good marks, though you'll probably struggle with the pocket microscope. Use of digital measurement is highly recommended.

Attached Files

Data for my homemade 10mm / 150 kg tester has been updated to include the “J.R.” brand of reclaimed shot.

Attached Files

I'm content with my Lee Hardness Test Kit. Something I noticed in the instructions turned out to be more important than I had expected from Lee. The Lee specified 30 second indentation time is very relative to consistency of the results from the Lee kit.

You can easily see for yourself testing soft alloys or pure Lead with the kit that a timed 35 second indentation measures bigger than a 30 second indentation. The elapsed time is a factor in use of the indentor. It will sink in deeper with time. At 40 seconds you can see the difference easily with the naked eye.

Consequently, I operate the kit with my watch on my press base in clear easy view to watch the time as I indent a sample bullet or scrap. It was a lesson to me. Really watch the clock!

Gary

Attached Files

Re: why did the Lee 5/32” / 60 pound test give decent results while my homemade 4mm / 60 pound test gave goofy -- and mostly high -- results?

For a while I suspected that anything other than a 10mm ball might skew the results, but the Lee tester proved that a smaller ball can work OK.

The bullet does not know which brand of tester is pushing on it, the bullet only knows that a certain diameter indenter is pushing on it with a certain force.

There is no dispute about the diameter of the indenter(s).

I used the same digital measurement system to measure the indentations with both the Lee tester and my homemade tester, and I have confidence in those measurements.

What I can't be confident about is the applied force. That is the weakness of any BHN test (other than Frnkeore's method, where the applied force does not matter because it cancels out of the equation).

There are always friction losses that we cannot measure. The friction losses subtract from the applied force and cause the indentation to be smaller, which makes the BHN appear to be higher than it really is.

In the case of my homemade tester, I have not been taking into account the weight of the moving parts. That's because they don't weigh much compared to the load. The moving parts weigh about 2 pounds, while my 150 kg test uses a 52 pound weight. Compared to a 52 pound weight, errors due to 2 pounds of moving parts or a few pounds of friction are small.

But my homemade 4mm / 60 pound test uses a 9.4 pound weight. Compared to 9.4 pounds, friction losses and the weight of the moving parts may be significant. I can't feel much friction, but the goofy results with a 4mm ball suggest that friction is there whether or not I can feel it.

So .... I mentioned in a previous post that I was thinking about building a new homemade tester based on a “nutcracker” design. The simplicity of a nutcracker design means that it could be made to have minimal friction, and the weight of the moving parts could be easily accounted for. As time allows, I will try to build the nutcracker tester and see if it will work with a 4mm / 60 pound test. If not then I'll probably buy a Lee tester, but I'm betting the nutcracker design will work.

Attached Files

Re: new homemade BHN tester to fix the shortcomings of the original homemade tester. The goals were: - minimize friction. -- account for the weight of any moving parts. -- increase the leverage. I used a simple “nutcracker” design. There is only one pivot point so friction is minimal. It has 7.3X leverage in 4mm mode and 11X leverage in 10mm mode. The weight of the lever arm is included when calculating the applied load. There's not a whole lot to go wrong with this simple design, so it oughta work. ![]() Sorry for the cluttered photo, I'll post a better photo after the tester is completely finished. The tester clamps in a bench vise. When not in use it will hang on the wall. The load consists of a bucket containing scrap metal. It was weighed on a digital postal scale and metal added until the desired weight was reached. A notch in the lever arm makes sure the bucket sits in the right place. The load is applied for 30 seconds as per standard procedure for any BHN test.

Sorry for the cluttered photo, I'll post a better photo after the tester is completely finished. The tester clamps in a bench vise. When not in use it will hang on the wall. The load consists of a bucket containing scrap metal. It was weighed on a digital postal scale and metal added until the desired weight was reached. A notch in the lever arm makes sure the bucket sits in the right place. The load is applied for 30 seconds as per standard procedure for any BHN test.  Results with a 4mm ball and 59.3 pound load. While not in 100% agreement with other tests, all results were at least in the ball park, and fairly consistent. I can live with this level of accuracy for measuring small caliber bullets.

Results with a 4mm ball and 59.3 pound load. While not in 100% agreement with other tests, all results were at least in the ball park, and fairly consistent. I can live with this level of accuracy for measuring small caliber bullets.  Tomorrow I will try to test the “nutcracker” with its 10mm ball and perhaps a 200kg load. Assuming it passes that test, I need to make adjustment knobs for the indenters, and then give the assembly a coat of paint, or perhaps powder coat. On another note, I've been wondering “what if I replaced the Cabine Tree's conical indenter with a 4mm ball?” :thinking:

Tomorrow I will try to test the “nutcracker” with its 10mm ball and perhaps a 200kg load. Assuming it passes that test, I need to make adjustment knobs for the indenters, and then give the assembly a coat of paint, or perhaps powder coat. On another note, I've been wondering “what if I replaced the Cabine Tree's conical indenter with a 4mm ball?” :thinking:

Attached Files

Re: digital measurement of indentations. A USB microscope is very nice for photographing indentations, but many ordinary cameras are capable of taking decent closeups.This was taken with a Canon S120 point & shoot, set to “macro” mode for close-ups. The resolution after cropping was only about half the resolution as my cheap USB microscope, but nonetheless it was sufficient to get the job done.

Attached Files

Testing the second homemade tester (HT2) with a 10mm ball and a 200 kg load. My original homemade tester used a 10mm / 150 kg test, because 150 kg was about the practical limit without pulling my reloading bench over. ![]() The thought behind increasing the load to 200 kg was to make a bigger indentation that would be easier to measure. Well, the 200 kg indentation was a little too much of a good thing, because it smushed a 45 caliber pure lead sample like a pancake.

The thought behind increasing the load to 200 kg was to make a bigger indentation that would be easier to measure. Well, the 200 kg indentation was a little too much of a good thing, because it smushed a 45 caliber pure lead sample like a pancake. ![]() Oops. It was kinda noisy on air-cooled wheelweight and didn't settle down until lino. In summary, 10mm / 200kg worked great on heat treated samples, but was too much for all around use.

Oops. It was kinda noisy on air-cooled wheelweight and didn't settle down until lino. In summary, 10mm / 200kg worked great on heat treated samples, but was too much for all around use.  This has been a fun project and I've learned quite a bit. The two biggest improvements were 1) using digital measurement rather than calipers and 2) eliminating friction losses and accounting for the weight of moving parts. As of this moment I would be equally happy using either the Lee tester or homemade tester #2 with 4mm / 60 pounds -- as long as I measure their tiny indentations digitally. Third place goes to my original homemade tester with 10mm / 150 kg. Frnkeore's method using a “cylinder sandwich” is also a viable option, though slower because twice as many samples and twice as many measurements are required. The Cabine Tree tester works well on softer alloys but accuracy is not-so-great on harder alloys. If time allows I want to try making a 4mm ball indenter for the Cabine Tree, and see if that helps.

This has been a fun project and I've learned quite a bit. The two biggest improvements were 1) using digital measurement rather than calipers and 2) eliminating friction losses and accounting for the weight of moving parts. As of this moment I would be equally happy using either the Lee tester or homemade tester #2 with 4mm / 60 pounds -- as long as I measure their tiny indentations digitally. Third place goes to my original homemade tester with 10mm / 150 kg. Frnkeore's method using a “cylinder sandwich” is also a viable option, though slower because twice as many samples and twice as many measurements are required. The Cabine Tree tester works well on softer alloys but accuracy is not-so-great on harder alloys. If time allows I want to try making a 4mm ball indenter for the Cabine Tree, and see if that helps.

Attached Files

The experimental indenter for the Cabine Tree tester, with a 4mm ball.  As best I could measure, the Cabine Tree's spring has a spring rate of 146.5 lb/in. The initial preload is 0.316", which generates 46.3 pounds force. Turning the screw one turn as per the instructions can increase that force to up to 60.9 pounds, though in practice the force will always be less because of the indentation taking up some of the screw movement. The hope was that the 4mm ball would be more sensitive to changes in BHN than the cone indenter. But in fact the 4mm ball was less sensitive. :X Chart shows the actual dial readings, not BHN. For example, with the 4mm ball there was only 0.004” difference between the air-cooled reclaimed shot (14 BHN with the Lee tester) and the oven treated reclaimed shot (35.9 BHN with the Lee tester), while the cone indenter had 0.0150” difference between those alloys.

As best I could measure, the Cabine Tree's spring has a spring rate of 146.5 lb/in. The initial preload is 0.316", which generates 46.3 pounds force. Turning the screw one turn as per the instructions can increase that force to up to 60.9 pounds, though in practice the force will always be less because of the indentation taking up some of the screw movement. The hope was that the 4mm ball would be more sensitive to changes in BHN than the cone indenter. But in fact the 4mm ball was less sensitive. :X Chart shows the actual dial readings, not BHN. For example, with the 4mm ball there was only 0.004” difference between the air-cooled reclaimed shot (14 BHN with the Lee tester) and the oven treated reclaimed shot (35.9 BHN with the Lee tester), while the cone indenter had 0.0150” difference between those alloys.  I also tried testing both indenters with 2 turns of the screw, in addition to the normal one turn. I was hoping the extra force might improve sensitivity, but it didn't. So I have to admit defeat at improving the Cabine Tree tester.

I also tried testing both indenters with 2 turns of the screw, in addition to the normal one turn. I was hoping the extra force might improve sensitivity, but it didn't. So I have to admit defeat at improving the Cabine Tree tester. ![]() It is what it is. It's very well made, it's fast and easy to use, and it gives good results with soft alloys. If you only shoot black powder, the Cabine Tree would probably serve you well. But if you shoot a lot of harder alloys, the Cabine Tree is not the best tester.

It is what it is. It's very well made, it's fast and easy to use, and it gives good results with soft alloys. If you only shoot black powder, the Cabine Tree would probably serve you well. But if you shoot a lot of harder alloys, the Cabine Tree is not the best tester. ![]()

Attached Files

This chart may be helpful to Cabine Tree owners. Let me know if you can't see the chart -- I'm still trying to figure out my new-to-me photo host.

Attached Files

Here's a better picture of my “nutcracker” BHN tester, “homemade tester #2” or “HT2” for short. Today I ran a side-by-side comparison test of HT1 and HT2. For HT1 I used one measurement for each alloy, while for HT2 I used the average of 5 measurements for each alloy.

Today I ran a side-by-side comparison test of HT1 and HT2. For HT1 I used one measurement for each alloy, while for HT2 I used the average of 5 measurements for each alloy.  And here's a graph of that data. The two homemade testers roughly agree below 25 BHN, then diverge on the heat treated samples. Which tester is closer to the truth? I dunno. Digital measurement of the indentation is pretty accurate, so the weak link is any error in the applied force due to friction losses or due to error in measuring the leverage. I can say that HT2, with its 4mm ball and 60 pound load, agreed very closely with the Lee tester's 5/32” ball and 60 pound load. I can also say that HT1, with its 10mm ball, agreed very closely with the “cylinder sandwich” method, which also used a 10mm ball. The “cylinder sandwich” method eliminates any error in the applied force so I would expect its results to be in the ballpark.

And here's a graph of that data. The two homemade testers roughly agree below 25 BHN, then diverge on the heat treated samples. Which tester is closer to the truth? I dunno. Digital measurement of the indentation is pretty accurate, so the weak link is any error in the applied force due to friction losses or due to error in measuring the leverage. I can say that HT2, with its 4mm ball and 60 pound load, agreed very closely with the Lee tester's 5/32” ball and 60 pound load. I can also say that HT1, with its 10mm ball, agreed very closely with the “cylinder sandwich” method, which also used a 10mm ball. The “cylinder sandwich” method eliminates any error in the applied force so I would expect its results to be in the ballpark.

Attached Files

Very interesting. Glad I didn't bet on the outcome. I would have bet against getting such good agreement with the two different size ball indentors.

<"And here's a graph of that data. The two homemade testers roughly agree below 25 BHN, then diverge on the heat treated samples. Which tester is closer to the truth? I dunno.">

If truth is defined as being in agreement with the standard ASTM test results, it seems that the one with the same size ball as the standard (10mm.) is the more likely assumption. It is a pity you got to this stage just after my recent move or I could have done comparison testing in a lab with an actual Brenell testing apparatus meeting ASTM E10-14. I am kicking myself for not thinking of that earlier.

<"Digital measurement of the indentation is pretty accurate, so the weak link is any error in the applied force due to friction losses or due to error in measuring the leverage.">

Spoken as a careful experimenter should. But I think you are too modest. The error in measuring the weight of the lever arm and the distances that make up the leverage could easily be very precise, much smaller than the difference in results on the harder materials. Friction,with almost any reasonable joint, at the fulcrum should also be tiny or could be made tiny. It seems to me that reducing the percentage of error is probably more difficult in measuring the tiny indentations, whether done with the aid of a computer or not, but then I haven't done that trick and maybe it can be magnified without distortion so the percentage of measurement error is small.

John

Attached Files

Thanks for reading my nerdy post on BHN, John. :)

You had access to a laboratory BHN tester? Dang. that would be nice. I've never seen one, but some googling turned up

I agree with you that the official 10mm indenter is more believable, at least until better data comes along.

One more variable might be microscopic surface imperfections. Even though I filed the surfaces, filing leaves microscopic striations that are visible in my photographs. A 4mm / 60 pound test is probably more sensitive to microscopic imperfections than a 10mm / 150 kg test.

Frnkeore's method eliminates the force issue so if I wanted to make a career out of measuring BHN I suppose I could arrange to repeat the “cylinder sandwich” method with a 4 mm ball and see how it compares to a 10mm “cylinder sandwich."

Attached Files

Very interesting. Anybody still trying the artist's pencils method any more?

Attached Files

Very interesting. Anybody still trying the artist's pencils method any more?

I have not tried it myself, but it seems popular at the spelling-challenged site.

On an unrelated note, I stumbled across

Attached Files

Very interesting. Anybody still trying the artist's pencils method any more?

I put Ken Mollohan's article on pencil- lead- hardness- testing up here, somebody took it down. Not scientific enough, perhaps.

Attached Files

And disrespectful, as well joe, considering he was one of the founders of the CBA!

Attached Files

I'm about convinced to buy the Lee tester. I have scrounged a lot of lead over the years and most of it is a mystery alloy. I think I may even have what I've been told is submarine weights. Movable ballast I guess. The old WWII sub base is not that far. May have traveled over here. Nobody alive knows what's in it but all I really need to know is approximately how hard it is. Something a little more specific than the thumbnail test. I confess to being the least scientific CBA member in my neighborhood!

Attached Files

I have the Lee tester but have started using the pencil more. For someone with poor eyesight the Lee tester is difficult to read. I would love to find an old microscope to use one day. THe pencils run pretty good, just make sure you keep the edge sharp. I was skeptical at first but now am comfortable with a #2 pencil at the scrap yard.

Jim

Attached Files

Just as a matter of (perhaps) interest to the person who posted about the possible submarine ballast: As I have read in my studies, virtually every D/E (Diesel/electric) boat launched, (at least the Balao Class) shipped approx. 65 tons of lead ballast. This varied according to any configuration change: if a deck gun was installed, from a 3” bore, up to the 5” 28 that could be installed fore or aft of the conning tower, Skipper's preference. The Installation configuration dictated quantity of lead required. I realize this has little to do with cast bullets, I just thought some folks might be interested.

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

mntngn, "A USB microscope is very nice for photographing indentations,” What is a “USB microscope” , Where can I get one and approximately how much does one cost?

Lifetime NRA since 1956, NRA Benefactor, USN Member, CBA Member

Attached Files

A USB microscope is a digital camera/microscope that runs off a USB port on your computer. They generally use webcam software to run the scope, though some are supplied with their own software.

I'm still experimenting with different free webcam softwares. Some only take 600 pixel photos while others go up to 1600 pixels. More pixels is better. Some do a better job of controlling the lighting than others. I've found that turning the scope's light way down and shining a flashlight on the specimen at an angle gives better definition of the indentation.

Both Gimp and Irfanview are free graphics programs that have a “measure” tool that allow you to measure the width of the indentation in pixels and compare it to the scale that you'll need to include in the photo.

Attached Files

If you have the program, On Target (part of QL or seperate), you can do the same thing. You use your camera and import the picture to the program. You still must include a scale in the picture. Frank

Attached Files

On second thought, you do not have to include a scale. You only have to mic your bullet base and use that dimension as the scale, for both the On Target and mtngun's system.

Frank

Attached Files

In an effort to better understand why a 10mm test seems to read higher BHN than a 4mm test, I did a side-by-side comparison using the “cylinder sandwich” method with both 4mm and 10mm balls. The cylinder sandwich method eliminates any error due to applied force because both samples receive exactly the same force and it cancels out of the BHN equation. The only remaining error is in how well you can measure the indentations, and that error is negligible using digital photo measurement. I made a gadget to hold two 4mm balls in the center of the 1/2” slitted pex.  Initially I ran this test with the “NRA equation” that someone had posted. Later I went back and worked out the math from scratch and came up with a different equation, below. It's late at night and I'm tired so feel free to check my math and tell me if you find a mistake.

Initially I ran this test with the “NRA equation” that someone had posted. Later I went back and worked out the math from scratch and came up with a different equation, below. It's late at night and I'm tired so feel free to check my math and tell me if you find a mistake.  The test results data:

The test results data:  The test results graphed. As you can see, the 10mm ball read higher than the 4mm ball, more so on the harder bullets. I don't know why this is so, I only know that the results are repeatable, so it appears to be a fact of life.

The test results graphed. As you can see, the 10mm ball read higher than the 4mm ball, more so on the harder bullets. I don't know why this is so, I only know that the results are repeatable, so it appears to be a fact of life.  Which is more correct? Well, if you believe that 20:1 should be 10 BHN and linotype should be 21.5 BHN, then the 4mm results look reasonable and the 10mm results look too high. At this moment I have no explanation but I'll continue to investigate as time allows.

Which is more correct? Well, if you believe that 20:1 should be 10 BHN and linotype should be 21.5 BHN, then the 4mm results look reasonable and the 10mm results look too high. At this moment I have no explanation but I'll continue to investigate as time allows.

Attached Files

You've gone through a lot of work in doing all that, thank you.

I have some more info that I'll post a little later. I have to photograph it first.

Frank

Attached Files

goldilocks might pick a lucky 7 mm ball ...

wonder where that dang formula came from anyway ...

good stuff .... it makes me nervous when experiments come out just the way they were predicted ....

ken

Attached Files

I edited post #47 to use my equation for the “cylinder sandwich” instead of the “NRA equation.” It's late at night and my brain is not firing on all cylinders so you won't hurt my feelings if you check my math and point out any errors. :D :D :D

Attached Files

I'm sorry that I'm late (again) with getting the info to you, that I wanted you to see. In E.H.H. other info on testing, he states that you need a ball of at least 1/2” diameter, in this one, he says that 1” is best. My 5/8's ball was the closest I had on hand.

I don't know if you've heard of the Meyer Hardness test (I hadn't) but, it seems to have some relavance.

<url=http://www.digplanet.com/wiki/Meyer_hardness_test>http://www.digplanet.com/wiki/Meyer_hardness_test</url>

I hope this info many be helpful in your testing. I've enjoyed your results very, very much.

Frank

Attached Files

Thanks for the good info, frnkeore. :)

I interpret E.H.H. as saying a large indenter is better because big indentations are easier to measure than little indentations ???

Dennis Marshall sometimes used the Meyers test. If I remember correctly, Dennis stated that you could convert Meyers to BHN simply by subtracting 1, but your link suggests that the relationship is non-linear.

Attached Files

I wanted to try the pencil method just to say that I tried it. :D

The name brand pencils that were recommended:

Attached Files

There is a trick to the pencil test, an artist friend pointed out to me. The shape and condition of the point of the pencil lead is IMPORTANT. A sanded flat point then scribbled on paper to smooth the flat and round the sharp off the edge works best. If you have a sharp edge or a sharp point that catches, the test will be erratic and inaccurate. You have to decide if the pencil will only write on the test sample or if it will scratch the sample.

The test works as well as you do it and I was happy with the method after I played for a while. I believe it is a useful test method. The pencil set I got cost me $10 at OfficeMax.

Gary

Attached Files

Very interesting. This scratch approach is the same tactic geologists use to measure mineral hardness. The “scratchers” are ten known minerals ranging from talc to diamond if I am correctly remembering my geology class from 60 years ago.

I gotta have a set of those pencils.

There is no end to the stuff to learn. John

Attached Files

Very interesting. This scratch approach is the same tactic geologists use to measure mineral hardness. The “scratchers” are ten known minerals ranging from talc to diamond if I am correctly remembering my geology class from 60 years ago.

I gotta have a set of those pencils.

There is no end to the stuff to learn. John EXACTLY John! I remember Earth Science Lab in high school learning how to preform the Mohs Hardness Test with mineral samples. It takes a good skilled hand to do that well, but is a good test.

Gary

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

Aaron

25

Aaron

25

-

jeff houck

20

jeff houck

20

-

Tom Acheson

17

Tom Acheson

17

-

Wilderness

14

Wilderness

14

-

John Carlson 13

-

sghart3578 10

-

MarkinEllensburg

10

MarkinEllensburg

10

-

Spindrift

5

Spindrift

5

-

alphabrass

5

alphabrass

5

-

SkinnerD 5