I started the thread “Why all the lube grooves.” To see what is known about the need for multiple lube grooves so perhaps they could be eliminated. The thread has morphed into an interesting discussion about breech seat and especially breech seating with gas checks in bolt actions. Individually breech seating the bullet is an appealing idea. The known drawbacks are complicated devices and loading time at the bench. Nothing wrong with the fuss and I kinda like doing it myself but it is slow and complicated. I will be interested in the outcome of this experimentation being discussed on the Why all the lube grooves thread. However I am even more interested in doing breech seating or a close enough approximation to breech seating to get the good out of the principle but with fixed ammunition which would eliminates a lot of the fuss. It seems to me that John Ardito essentially accomplished that years ago with a system of bullet design, swaging, and fit to throat that shoots as well as the best breech seaters. Others have done it with different bullet designs and swaging bullets into a die cut with the same reamer as the throat. My interest is to find a bullet design that will approximate the benefits of BS in a factory chamber and without the swaging step or the custom chamber. What I have been shooting in competition is pretty close but limited by non-custom match grade barrels and throats, factory triggers, and my shortcomings. That is why I was trying to determine if those extra grooves were of any use. Although there are theories about what they might do that is useful as far as I know none of it has been proven. I think the main reason for them is that they were needed for black powder and now may just be customary. The only way to find out is with a bullet designed without them and with good fit at the time when only a short length bullet is in the case. It may take stepped case mouths and other tricks but progress in this direction would benefit competitive shooters in production or hunting rifle class and any of the military classes as well as anyone else wanting better accuracy in a factory rifle. How close are we coming to breech seating with fixed ammunition? And what is the best way to proceed? John

How close can we come to breech seating with fixe ammo?

- 12K Views

- Last Post 12 December 2014

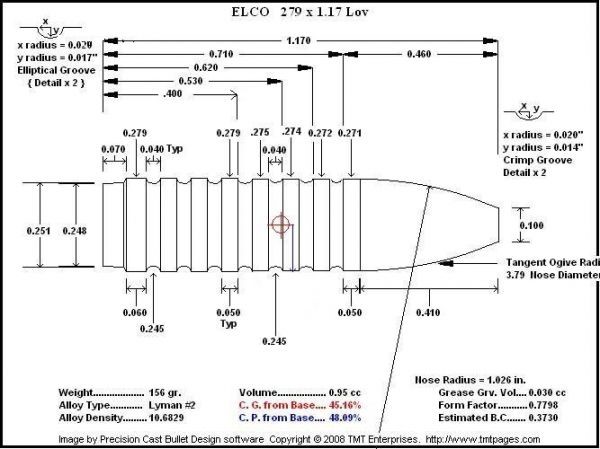

John,Your options are extremely limited if you can't throat the chamber. I believe production class does allow throating and the Hunter class doesn't, right? So, for Production, you can have a freebore that takes all the bullet, accept the GC. But, here you limit yourself to a paticular bullet design. For the Hunter class, all that you can do is to use a long bore rider and match the first band or multiple bands to the leade angle. Using the bolt to push the bullet with a steped mouth case, won't get you very much, at all with a bullet over 12 BNH. I designed a 270, loverin style bullet (160 gr) to do just that, using steped bands to match the taper of the leade. I only shot it once so, the jury is still out (2” group @ 100). The velocity was limited with that powder cavity (2.25 cc) to under 1700 fps with 4227 & 300MP in that test. I'll try a nearly full case of Varget, next time out. It's a machined case with a .272 hole back to the primer pocket and a .279, to match the base bands. It starts out jamed into the throat about .010, enough to engrave the bullet on all the throats area. For a long throated Production rifle, you can make a solid brass case and push the bullet in as far as the freebore will allow and adjust the freebore to get all but part of the GC in the throat. You could go shorter or longer with a adjustable, bullet size piston inside the case. You can, of course do the samething in the Heavy and Unrestricted classes. My 270 mold that matches the 270 Winchester throat. Frank

Attached Files

What caliber?

I lapped the RCBS 165 Sil mould to make bullet bands larger and bore ride section .0005-.001 larger and more round. I then “lapped the throat area of barrel LARGER to accept the new larger size bore rider bullet". This allowed for easier chambering and extraction of loaded rounds, but also kept bore ride tight during trip down barrel. I can load rounds that have a better/longer over all length (front band touches rifling when chambered). My rifle has a free bore length of .090.

7mm-08 brass is longer and can be formed to 308 and be trimmed to longer 2.030 length. Case will shorten to 2.025 when fired.

Lately I have had good results using my 308 with 22grs of 4759 powder (1900fps), Wolf LR primers, RCBS 165 Sil cast with linotype (water quench), Lyman Moly lube.

Attached Files

Things to consider:

Production rifles have up to .004 - .005 clearance between the chamber neck and cartridge neck.

When the powder gas expands the case, there is no way to keep the part of the bullet that occupied the neck, in alignment with the throat and barrel.

That same part of the bullet is free to expand itself (with enough pressure)to the limits of the expanded neck. It then has to conform back to the shape of the throat and barrel.

Remember that in front of the case mouth, there is a transition from the chamber neck to the throat or freebore. In most modern chambers that is 45 degrees and at can effect the size and transition back to the throat.

The hardness of the brass effects all the above, too so, two cases that have a different neck and shoulder hardness, can act differently.

BSing eleminates all the above and starts the bullet straight and concentric, into the bore.

Just thinking about it, I would say that the best bet for a Hunter chamber, would be to have a long bore rider with the base band, the width of the freebore and the GC (if used) next to base band.

Then put the grease groove and the front band in the taper of the angled leade. That band as large as it can be and still seat the bullet, say .304 in a .308 barrel and transition at the leade angle down to the bore ring nose. I would also start with the nose .002 over bore diameter to get as much purchace on the lands as possible.

Frank

Attached Files

The RCBS 165 Sil bullet has a short enough band area so that you can get most of it inside freebore for good support. Gripping just the base of bullet with case neck, some bore riders are short enough to fit magazine.

Bore riders are boring, but can be made to shoot just as well as tapered designs IMO.

Attached Files

The lapping, while being helpful, wouldn't comply with the rules in the Hunter class.

Frank

Attached Files

How close are we coming to breech seating with fixed ammunition? And what is the best way to proceed?

John

I have been thinking about breach seating my Remington 700. I have read that you can put Dacron inside case to prevent powder from spilling. You may have to design a special bullet with very short band surface.

Is their an advantage? All of bullet is tapped into Free bore and throat with wooden dowel (guided by dummy case with hole drilled larger at primer pocket). A short band surface may slip/skid on rifling when fired? A factory rifle with long free bore (longer band surface) would have advantage. My factory Remington has a free bore length of .150"...longer would help more.

Would this guarantee better accuracy over fixed ammo?

Attached Files

My friend Harry Williamson shot benchrest with a 30BR...he would bump the bullets ala Ardito and then turned the case neck, fire form and leave a donut inside the case...this shoulder was whatever distance he needed to force the bullet into the throat...seemingly breech seating with fixed ammo..the chamber was cut to fit his brass by one of the benchrest gunsmiths at the range I shoot at....Harry was a SEABEE in WWII, in the South Pacific and succumbed to cancer this year...look back in the fouling shot and his name appears

Attached Files

It's a good question, and I wouldn't use the word “guarantee” very much when dealing with cast bullet shooting. However, breech seating the bullet to full engraving will eliminate the launch from the case neck, when even a tight chamber will leave the bullet somewhat unsupported for a fraction of a second as it moves into the rifling.

Larry Gibson has done several tests using his Oehler 43 Personal Ballistics Lab, and on the graphic printout of the bullet's pressure curve there is a small “blip” that signifies a slightly lower pressure AFTER the bullet leaves the case neck but BEFORE it engraves in the rifling. Breech seating would ensure an absolutely straight launch of the bullet, and down the road we'll have Larry do some breech seating to see if this method results in a more even pressure curve.

As for John's original question about how close we can get to breech seating with fixed ammo, my personal observation would say “not close enough", unless we start loading bore riders with undersized noses, or possibly size down the noses of other types bullets (I have a nose sizer made to fit in a Lyman 4500), but this form of loading has never given me any appreciable increase in accuracy.

Oh BTW I don't think dacron is the optimal method to stop powder spillage. Frnkeore mentioned floral foam; I'll be trying that before anything else.How close are we coming to breech seating with fixed ammunition? And what is the best way to proceed?

John

I have been thinking about breach seating my Remington 700. I have read that you can put Dacron inside case to prevent powder from spilling. You may have to design a special bullet with very short band surface.

Is their an advantage? All of bullet is tapped into Free bore and throat with wooden dowel (guided by dummy case with hole drilled larger at primer pocket). A short band surface may slip/skid on rifling when fired? A factory rifle with long free bore (longer band surface) would have advantage. My factory Remington has a free bore length of .150"...longer would help more.

Would this guarantee better accuracy over fixed ammo?

Attached Files

Lot's of good comments. I have some comments on the comments.

Frank's comment in post#2 That for a factory chamber and throat a long bore rider is the best matches my efforts and it works fairly well if you can get the right dimensions. OU812 comments on the RCBS 165 SIL describe an example of approaching this with a commercial mold. Frank's “Things to consider” list sets out the problem as I too see it. As far as his proposed solutions the idea of a front band with tapered to match the leade sounds great but I have not been able to actually get that in a custom mold and have decided it is something I may be able to do without. It seems to me that the trick is to find that right dimensions for the bullet that will minimize the amount not supported when chambered but have enough driving band to avoid excessive skidding and still be able to chamber with reasonable force. I believe finding those dimensions will require being able to examine fired and undamaged bullets for one thing. Bjornb says: “my personal observation would say “not close enough", unless we start loading bore riders with undersized noses.” I believe you can get close enough to make it hot on other competitors using other approaches in the classes for factory chambers. I agree that a bore rider seems the only way to go for factory chambers and that's what I am trying to do except I am puzzled by the “undersized” description for the noses. The ideal size for noses would be big enough to get full length engraving and as deep engraving as possible without making chambering too difficult. Of course this depends on several things including alloy hardness. John

Attached Files

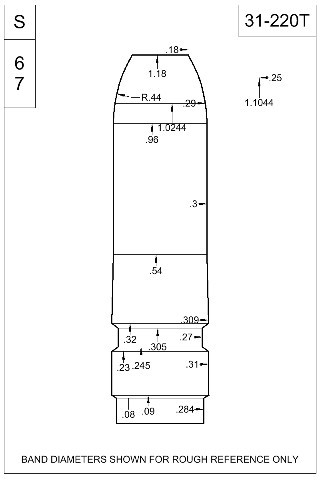

My attempt at breach seating. Here is a bullet that I had drawn up and had Tom at accurate Molds cut for me. 31-220-T. It turned out to be 220 gr.bullet bore riding shooter and is only held by the case just a little past the gas check. Seating depth past the neck is .110. Bullet cast from my mold .3005 on the nose and .310 on the driving band. I shoot the bullet in my Remington 700 SPS Varmint rifle in 308W. I made no changes to the throat and size the bullet .3095. The nose is supported in the bore and the tapered part of the bullet in front of the lube grove is seated into the lands when loaded. OAL is 3.095. If you look real close at the picture you can see the marks from the lands on the bullet. On the target the first shot went high out of the clean barrel. The 10 shot group discounting the first shot measures about .850 C/C. I load 27 grs. 3031. Mr. Bill2

mrbill2

Attached Files

Accurate Molds is a good, inexpensive source of molds, The only reason that I've not used him, is becauce he won't make spitzer noses. I think he would get between 1/4 and 1/3 more business if he would.

Frank

Attached Files

John Alexander wrote: Lot's of good comments. I have some comments on the comments.

Frank's comment in post#2 That for a factory chamber and throat a long bore rider is the best matches my efforts and it works fairly well if you can get the right dimensions.

OU812 comments on the RCBS 165 SIL describe an example of approaching this with a commercial mold.

Frank’s “Things to consider” list sets out the problem as I too see it. As far as his proposed solutions the idea of a front band with tapered to match the leade sounds great but I have not been able to actually get that in a custom mold and have decided it is something I may be able to do without. It seems to me that the trick is to find that right dimensions for the bullet that will minimize the amount not supported when chambered but have enough driving band to avoid excessive skidding and still be able to chamber with reasonable force. I believe finding those dimensions will require being able to examine fired and undamaged bullets for one thing.

Bjornb says: “my personal observation would say “not close enough", unless we start loading bore riders with undersized noses.” I believe you can get close enough to make it hot on other competitors using other approaches in the classes for factory chambers. I agree that a bore rider seems the only way to go for factory chambers and that’s what I am trying to do except I am puzzled by the “undersized” description for the noses. The ideal size for noses would be big enough to get full length engraving and as deep engraving as possible without making chambering too difficult. Of course this depends on several things including alloy hardness.

John

John,what I mean by “undersized noses” is actually what mrbill2 is showing in his post. He has a bore rider that is perfectly matched to his rifle, and then I cannot call it undersized. However, testing has shown us that bore riders are only accurate up to a certain velocity; past this we need more bearing surface for accuracy. Here's a picture illustrating what we are working with:

Attached Files

Obviously trying to breech seat this bullet with fixed ammo won't work; it will get pushed back into the case. So you would either need a bore rider bullet, or else use a Nose Sizer (I have one, made by Buckshot over on Cast Boolits). It uses Redding style neck sizing bushings and will size the bullet nose down to match your bore dimension.

Attached Files

If that bullet is the NOE 165, it's actually a re-sized tapered nose at tapers down to .299, It has bore riding aspects, you might call it a simi-bore rider, as it would be in the bore riding class until half way up the nose.

I'm not criticizing it, just classifing it. The nose is very simular to the RCBS 200 Sil.

Frank

Attached Files

Well, this bullet is currently outshooting every cast bullet I've ever tried, at all velocities and in a multitude of rifles, and it's the bullet that Tim specifically made his breech seater for. It starts engraving immediately past the ogive: (Never mind the flat nose from beating it out of the bore)

Attached Files

"I'm not criticizing it, just classifing it."

BSing is very design tolerant, as long as it doesn't take to much effort to get it in the barrel. I've always looked for higher BC's to help wind drift, too. Frank

Attached Files

I know you weren't criticizing it Frank, I just wanted to brag about the bullet. Al Nelson at NOE did a great job with Tim Malcolm's design.

Attached Files

Just a note: The cases I'm currently using are on the short side at around 2.005. I'm working on some longer cases made from 06 brass the will chamber in my rifle at 2.034, but need the make a mandrel to turn the necks. I should then be able to shorten the bullet by .020 from the rear and that along with the longer case move the bullet forward another .020. and still hold the bullet by just .110. I'm thinking that might improve performance just a bit. My velocity currently is 1800 fps.. All I'm doing is target shooting and that seem to work ok to punch holes.

mrbill2

Attached Files

My attempt at breach seating.

Here is a bullet that I had drawn up and had Tom at accurate Molds cut for me. 31-220-T. It turned out to be 220 gr.bullet bore riding shooter and is only held by the case just a little past the gas check. Seating depth past the neck is .110. Bullet cast from my mold .3005 on the nose and .310 on the driving band. I shoot the bullet in my Remington 700 SPS Varmint rifle in 308W. I made no changes to the throat and size the bullet .3095. The nose is supported in the bore and the tapered part of the bullet in front of the lube grove is seated into the lands when loaded. OAL is 3.095. If you look real close at the picture you can see the marks from the lands on the bullet.

On the target the first shot went high out of the clean barrel. The 10 shot group discounting the first shot measures about .850 C/C. I load 27 grs. 3031.

Mr. Bill2

Very good job of designing. Tom's lathe bored molds make very good round bullets. I like the two cavity aluminum version.

Attached Files

John,As to your original question about how close we can come to breech seating with fixed ammo: The bullet pictured below is the ACE Heavy 225-70. It allows me to seat all the way out to the gas check in my Mossberg Predator in 223 Rem. I have a number of these cast of Lino, sized .226 and lubed with Lars BAC, I'll be happy to send you some to try in your guns. I know you shoot 22 cal, so I figured I'd offer.

Attached Files

bjornb. Yes I would be very interested to have a few of your bullets. I would be more than happy to pay the freight. Or if you were interested I could send a batch of my new NOE22780SP in lino or WW sized to .226” and lubed with LBT Blue. I am traveling and won't be home for four days or so action on my end will be a little slow. John

Attached Files

No prob. Just PM me your address and I'll get them out. I'm mostly shooting 22 cal. cast in my .222 Rem., so I'm pretty much limited to bullets in the sub-50 grain range (1:14 twist). I'll also throw in a few other .22 cal bullets that are on the heavy side. Bjorn

Attached Files

before we give up on the mann-neidner system ... our modern chambers are not cut for that system.

the neidner system is a long bore rider front, with a single large base band ... the neidner throat has very little groove dia. freebore ...the nose is engraved immediately and 90 % of the bullet is located by the time the cartridge is fully seated.

a neidner bullet in a modern chamber with 50% length groove dia. ( plus 0.005 .. ) free bore is very poorly supported at lift-off. won't win cba matches.

full disclosure :: i am a fan of the neidner rifles and era.

also fwiw, i also suppose that the bore riding portion probably randomly slumps a bit upon ignition .

and yep a tapered bullet in it's tapered womb keeps popping up as the best bet. maybe. ( g ) .

in a modern factory chamber, perhaps the bullet should only be as long as the groove diameter is supported by the taper ?? i calculate about 1/4 degree per side for decent b.c. bullets ... does your remmy fall into that design ?

ken

Attached Files

My Rem 700 is a bone stock rifle, mid 60's manufacture with very few rounds down the pipe, so I would assume it has a very stock SAAMI chamber. I tried shooting heavier (longer) bullets in the rifle, but it clearly won't stabilize anything much over 55 grains. My bullet of choice is the NOE 226-45 RF2, cast from Lino and loaded over about 12 grains of RL-7.

Attached Files

As one who had considerable input to Tim and Al in the design of the NOE XCB bullet I can tell you it is not a “bore rider” or a “semi bore rider". The XCB Bullet is designed with the bearing surface being from the GC at the base of the 30 CXB neck (30-06 length neck) to the beginning of the leade. The ogive is then mated to the angle of the leade and tapers to the nose. No part of it rides the bore and was not designed to ride the bore in any way. There is 55% of the bullet as bearing surface to the beginning of the leade. An additional 13% of the bullets length is mated to the leade angle. That gives the bullet 68% of it's length supported as bearing surface. As mentioned the ogive tapers away from the top of the leade (bore diameter) to the nose and does not ride the bore what so ever.

As Bjorn mentions cast bullets are indeed accurate only to a certain level of velocity (RPM actually as the velocity level is dependent on the twist) that the XCB bullet exceeds in all twists. I have been testing extensively in 10, 12 and 14” twist barrels (all .308Ws) and the only other 2 cast bullet designs that approach the velocity with acceptable accuracy performance of the XCB bullet are the 311466 Loverin design and the LBT 30-160-SP which has similar design attributes to the XCB bullet.

LMG

Concealment is not cover.........

Attached Files

If you do decide to lap the land area just ahead of throat larger, make sure you have lapping compound on lead lap before pulling thru barrel. I made the mistake of pulling dry lap thru barrel without lapping compound and lap got stuck inside barrel. I had to remove barrel then heat in oven on self clean mode (1000 degrees) to melt out lead lap. This did not seem to harm barrel and Cerakote finish was not damaged, only a little black dusting of flat black coat.

If you do decide to lap your mould larger and more round, be sure to keep mould closed tight and not open during lapping. Any coarse compound between halves will cause bullet to be out of round. I drill a small hole in bullet base while clamped inside mold, then screw in small phillips head wood screw, apply small amount of lapping compound with tooth pick to cavity being sure not to get any outside of cavity and none around gas check and base area. Electric drill and Coarse 120 grit works faster. A small amount of oil helps cut faster also.

Attached Files

"No part of it rides the bore and was not designed to ride the bore in any way"

The diameter from the ogive to at least .303 are typical bore riding diameters. From that point on it could be termed a tapered band as to the way it actually works.

The nose is actually very simular, but shorter, to the age old RCBS 200 Sil.

Does it really matter what what it's called or do you want a brand new term for it?

Frank

Attached Files

It was designed specifically not to be a bore rider in any form for the reasons already mentioned. It is named the “30 XCB". That should be sufficient for this particular bullet. I see no reason it needs to be named something else or “redefined". It is not a bore rider. And it does matter as the max bearing surface, minimal but adequate lube grooves and no bore riding nose are what defines it and has made it exceptionally accurate.

Yes a “brand new term” is probably in order; how about the “XCB” design. That's the name those of us who designed it came up with. That should be sufficient, at least for the basic design concept as the basic design parameters and concepts that make it inherently accurate, especially at high velocity, are certainly adaptable to other cast bullet designs for other calibers.

LMG

Concealment is not cover.........

Attached Files

If a new term is to be used, because RCBS first used that design (at least modern day), I would say it should be a RCBS tapered nose design. Or weren't you aware that RCBS had already done that?

Frank

Attached Files

Apparently you've not looked closely at the 30 XCB and noted the distinct design differences between it and the RCBS 308-165-SIL bullet.

The RCBS bullet has a much shorter bearing surface designed for the .308W neck length, a true bore riding nose and a single large and deep lube groove. It is those very 3 design features that were eliminated with the 30 XCB. It is the elimination of those design features of the RCBS bullet, which are copied by numerous other designs by different mould makers and custom designers, that makes the 30 XCB distinctly different. The 30 XCB does not have any of those 3 design features. It is those very design features that are preventing that design from achieving the accuracy at higher velocity.

The 30 XCB did not “copy” or imitate any other bullet. The 30 XCB was designed from scratch to fit a specific cartridge and throat. The 30 XCB was designed with the attributes needed for success at high velocity. The 30 XCB is proving very successful for what it was designed.

The designers of the 30 XCB named it the 30 XCB. Ergo, regardless of your opinion, the 30 XCB is the name.

LMG

Concealment is not cover.........

Attached Files

Larry,As I told bjornb, I'm not puting down the design, at all and we where talking about the nose design, nothing else. If you will read my post more carefully, you'll find that I was not refering to the RCBS 165 Sil, I was talking about the RCBS 200 Sil. It does have a tapered nose that goes from .301 (depending on alloy) to .309, over a distance of ~.400. So the 30 XBC isn't the first tapered nose bullet. As far as it being the best HV bullet design, that remains to be seen but, I don't fault it. It's worth a try, for sure. Frank

Attached Files

Okay, let's talk about the nose design. Obviously you still fail to grasp the concept. Let me explain it to you again; the nose of the 30 XCB, regardless of what you may think, is not a bore rider nor a “tapered bore rider". It was specifically designed to avoid that feature. The ogive starts at the beginning of the leade and is tapered only to fit the angle of the leade. From the point where the leade ends and the bore on top of the land begins the ogive continues to the point of the bullet. The ogive begins at .310 and is angled to match/mate with the angle of the leade of the 30 XCB chamber and continues on in ogive to the bullet point. At no point does any part of the bullet in front of the leade ride the bore or “taper". It is the curve of the ogive that is in front of the leade, not a “taper” as is evident on the RCBS bullets and most all “modern bore rider” designs.

Thus we see (apparently everyone but you) the 30 XCB is not a bore rider nor does it have a “tapered nose” let alone is the nose any where similar to either the 168 or the 200 gr RCBS SIL bullets which are indeed modern bore riders. Anyone looking at both designs side by side will note the distinct difference and lack of a bore riding nose , tapered or not, of the 30 XCB as compared to either the 165 or the 200 gr RCBS SIL bullets. The other design changes are also readily apparent.

You might take note of the bore riding nose of the RCBS 200 gr SIL bullet and just where is sits when the bullet is chambered; the nose sits well into the bore past the leade and “rides” the bore. The nose of the 30 XCB does neither.

No need to have your usual type of argument here. If you want to simply argue then you win, call the 30 XCB whatever you want. Nobody cares.

LMG

Concealment is not cover.........

Attached Files

"call the 30 XCB whatever you want."

I will call it a tapered nose bullet :) After all, I seemed to have helped in this project, too :) :)

Or any bullet with a straight taper that starts at the nose or nose area.

If it has something besides a straight taper we could call it something else.

Not to mention that it will have all the draw backs of a bore rider in the first ~.003 of that taper. There is nothing you can do about that.

Geeez, you would have though that I had call that bullet a dirty name :(

Chill out, larry,

Frank

Attached Files

That's fine Frank, call it what you want.

LMG

Concealment is not cover.........

Attached Files

Today I had time to try a procedure for making fixed breach seating cartridges. I removed the seating stem from my junk box 30-06 seater and adjusted it to make a hard roll crimp on the 06 case mouth. I belled a case with my Lyman M die to take the whole gas check of the bullet into the case mouth. I set the bullet and case under the die and crimped the bullet to the case mouth. It worked like a champ and chambered in two different rifles with .312” throats. I used the Eagan US30 first because it is tapered from.298” to .312” It chambered fairly easily in the 03A3 and the model 70 target rifle. I next tried the Lyman 314291 and it was too big and got shoved into the case. Both of these bullets were cast of a moderately hard alloy a little softer than lyman no.2. I didn't load any with primers or powder. I just wanted to see if the process could work. They de-bulleted every time and I was able to measure bullets for size change and get a look at engraving. I didn't see much engraving on the fronts of the tapered bullet but got a nice scuff all around the back driving ring indicating a seal. The bullets were as cast with the hornady gas checks seated but not crimped. Crimping the case mouths also crimped the gas check.

Attached Files

In 1993 Mark Penrod finished putting the Douglas best barrel on a 12/15 Martini action and chambering it for 30-30 with a tight neck.This rifle uses step-necked cases, turned for a distance outside, fired with COW a few times and the step moves inside the neck. Annealing is involved. The bullet goes in and is stopped by the step. The bullet won't shake out of the case with reasonable shaking. Best bullets are 311299, 314299 and 31141. Among others, a Borton Darr PB and 308403 and 311291 don't shoot as well.31X299 and 31141 are lubed now with Lyman Super Moly and sized ~3095.The case making process, lengthy and fiddly, sets the inside neck step to push the bullet first band edge against the ball seat stop, for a seal. The case neck is AROUND the bullet, not behind it. This gun will shoot any of the 3 bullets into small groups all day long, with boring regularity.The range doesn't allow loading at the bench from a powder measure, so recently I've shot by breech seating the bullet with a plugged case-up to the stop-then putting in a charged case, 14.5/IMR4227 for example, and a plastic wad, the cases charged behind the line.So, it ain't breech seated as far in as the SS wizards, it's GC bullets sans GCs, and the case goes around the bullet base. But i<size=t shoots, and has since February of 1993.>

Attached Files

Joe, that's incredibly cool. I've never heard of such a setup. I'd love to see those cases some day.

Attached Files

Bob Fitzgerald had a rifle and bullet where he dropped the bullet in, pushed the case in, the case seated the bullet and he fired the gun. I had a Schoyen Ballard and bullet in 38-55 that did the same, breech seated with the case mouth. Breech seating effort/business is about the dimensions of the chamber and bullet. It's easier to change bullet dimensions than chamber dimensions. Less permanent too-we can always sell or throw away the mold. If breech seating, eliminating the bullet leap from case mouth to chamber, is one of the ways to increase accuracy; then we need to think about how we can do that. I suspect that reduced accuracy is partly caused by bullets being pushed back into cases on chambering, varying effective case volume. A step-necked case eliminates this, and Mike Barrett has done work on cases that push the bullet into the chamber. My method, probably not original, works because Mark made the chamber neck .326". We can try making ex .308 from 30-06 or 30-30 from 38-55 to get more meat in the neck wall, but these meet with varied success-at least for me. I did have luck forming 300 Win Mag from 300 H&H. Some better scheme is needed, maybe putting .223 cases in .308 cases? The ideal is to have the bullet held in the case mouth so it can't be pushed back and does push into the chamber and make a seal, and sits in the case mouth so it comes out with no resistance, straight.

Attached Files

I have never tried breach seating, and am a total newbee to this , but could you put a canalure or ridge of brass on the inside of the neck and use that to seat a bullet into the rifling from the magazine. ( I wish I could provide a illustration here, but it is beyond my technical ability.) To do so you would need a rather long neck and a bullet and chamber that are “mated” together, or at least constructed to fairly close tolerances.

Many straight sided pistol cartridges cartridges have something similar could this be applied to a rifle round. Brodie

B.E.Brickey

Attached Files

one reason that my so-far-fantasy ” 6mm super rook ” system works so good .. in my mind ...is that it is a heeled bullet, and can be pushed into it's tight throat by the case.

if you just drop the bullet into the chamber can't you just neck size a case down a bit and push the bullet in ? run a 30-06 neck into a 270 neck sizer die. i don't see a pressure problem with cast bullet loads. or put a brass rod into the 30-06 case and seat then put in the charged case.

or use a heeled bullet.

ken

Attached Files

one reason that my so-far-fantasy ” 6mm super rook ” system works so good .. in my mind ...is that it is a heeled bullet, and can be pushed into it's tight throat by the case.

if you just drop the bullet into the chamber can't you just neck size a case down a bit and push the bullet in ? run a 30-06 neck into a 270 neck sizer die. i don't see a pressure problem with cast bullet loads. or put a brass rod into the 30-06 case and seat then put in the charged case.

or use a heeled bullet.

kenSo the “how” to breech seat includes

Heeled bullet

case mouth push in

some kinds breech seater push in

Attached Files

Unless we define BS as requiring the WHOLE LENGTH of the bullet in the throat and rifling, before firing there is already a lot of BS going on in CBA competition. Breech seating is a matter of degree. The use of a bullet like 3xx299 or the RCBS SIL bullets has MOST of the bullet in contact with the throat and bore so with a less strict definition of BS they qualify.

I believe I BS with either my Mos bullet or the newer NOE 22780 (both designed for this approach). I try to get a fit by luck, sizing, lapping, or beagling so chambering the bullet in my factory chamber requires about all the force I can muster and results in most of the length of the bullet in the throat or bore and only the gas check in the case. I don't think I am the only one.

If we accept this less than strict definition of BS then we should add plain old neck tension to Joe's list of ways to achieve BS. If we don't accept this less strict definition of BS then BS can't be achieved by healed bullets, or stepped cases either because both fail to have the entire bullet in the throat and bore.

At least some of the current CBA shooters in Heavy, UNR, and UNP classes use a similar method, only usually with custom throating and swaging, to fire groups with fixed ammunition comparable to the best plain base (breech seating) shooters.

Maybe we need a definition of BS that defines how much of the bullet should be in contact with the throat and bore to be called BS. 85% anyone?

John

Attached Files

The actual definition of Breech Seating is to install the bullet ahead of the case so, it can not be used in any class but, PB, Unp and Unr, I believe. And one thing that should be noted about actual BSing, is that when done that way, throating plays very little to no part in the accuracy of a firearm. We in Schuetzen use any type throat and get good to excellent accuracy. Any type, includes 15, 22 1/2, 30 and 45 deg in front of the case and also, includes freebores with long leades. One of, if not the main reason that we can get accuracy with those type throats, is because when using the steep throat, we use a tapered bullet to reduce the force when BSing. The first band is usually about 1/2 the groove depth.

It's fairly easy to get accuracy BSed but, it seems that the more the bullet has contact with the case, the harder it gets, without freebores and shallow leades to obtain accuracy.

Since 1985,I've helped many people get accuracy with their rifles when getting started shooting BSed. In that time, I've only had 3 that I couldn't get to shoot. A Ruger #1 in 30/30, original Stevens 25/20 (it only had .002 deep rifling and washed out throat) and a 32/20 on a 44 Stevens. Pretty good odds for accuracy with BSing, I would say.

Throating is allowed in Production, so, what I would suggest is to pick a bullet and throat a rifles freebore until only the GC is in the case neck.

For the hunter class, it's a uphill road but, I would try having a bullet made that is a fairly tight bore rider (maybe put a lube groove in it) with driving band/bands that only occupy what freebore and leade that the factory chamber has and a long enough GC shank to get only the GC into the case mouth.

Food for thought,

Frank

Attached Files

The actual definition of Breech Seating is to install the bullet ahead of the case so, it can not be used in any class but, PB, Unp and Unr, I believe. And one thing that should be noted about actual BSing, is that when done that way, throating plays very little to no part in the accuracy of a firearm. We in Schuetzen use any type throat and get good to excellent accuracy. Any type, includes 15, 22 1/2, 30 and 45 deg in front of the case and also, includes freebores with long leades. One of, if not the main reason that we can get accuracy with those type throats, is because when using the steep throat, we use a tapered bullet to reduce the force when BSing. The first band is usually about 1/2 the groove depth.

It's fairly easy to get accuracy BSed but, it seems that the more the bullet has contact with the case, the harder it gets, without freebores and shallow leades to obtain accuracy.

Since 1985,I've helped many people get accuracy with their rifles when getting started shooting BSed. In that time, I've only had 3 that I couldn't get to shoot. A Ruger #1 in 30/30, original Stevens 25/20 (it only had .002 deep rifling and washed out throat) and a 32/20 on a 44 Stevens. Pretty good odds for accuracy with BSing, I would say.

Throating is allowed in Production, so, what I would suggest is to pick a bullet and throat a rifles freebore until only the GC is in the case neck.

For the hunter class, it's a uphill road but, I would try having a bullet made that is a fairly tight bore rider (maybe put a lube groove in it) with driving band/bands that only occupy what freebore and leade that the factory chamber has and a long enough GC shank to get only the GC into the case mouth.

Food for thought,

FrankThe actual definition of breech seating is whatever we agree it is. You ain't in charge of my language. The CBA requires the bullet to stay in the case when shooken for fixed, and a bullet in a step necked case can be shooken and not fall out. Arguing about term definitions don't help, the object is to leap the half inch hurdle. And, nobody = zero averages were below the hurdle in 2014. and, the SS guys ain't making much progress. Time to take a new path, maybe just a few steps. H. M. agrees, he told me so.

Attached Files

Throating is allowed in Production, so, what I would suggest is to pick a bullet and throat a rifles freebore until only the GC is in the case neck.

For the hunter class, it's a uphill road but, I would try having a bullet made that is a fairly tight bore rider (maybe put a lube groove in it) with driving band/bands that only occupy what freebore and leade that the factory chamber has and a long enough GC shank to get only the GC into the case mouth.

Food for thought,

Frank Frank, I believe that is good advice because that's what I've been doing since the early 1980s as I tried to say in my last post. The only difference is I haven't monkeyed with the throat and don't think that is necessary with the right bullet for the same reasons that you say you can use any throat if you seat the bullet ahead of the case. Take a look at NOE 22780sp. It comes pretty close to that in a SAAMI chamber. I have a bullet on order that I believe will come even closer.

I don't care whether we call it breech seating or something else. My original post starting the thread was to ask how close can we get to full breech seating with fixed ammunition. I think the discussion has shown that it is possible to get pretty close with the ways Joe lists and I think I am getting about as close with my approach which relies on neck tension. . I think with a benchrest quality chamber the effect of the case on accuracy would be nil but my interest is doing it in a practical factory hunting rifle and I don't expect to every shoot quite as well as the specialized, custom made benchrest guns which is OK. it's my windmill.

John

Attached Files

John, Do you have only the GC in the neck of the case? I didn't say it my post but, I always assume that the bands will fit the freebore with at least a size for size fit and the bore ride at a min of .001 interference fit.

Frank

Attached Files

John,

Do you have only the GC in the neck of the case?

I didn't say it my post but, I always assume that the bands will fit the freebore with at least a size for size fit and the bore ride at a min of .001 interference fit.

Frank Frank, Seating depth depends on which bullet and which rifle. With the new NOE bullet just a tad more than the gas check is in the case in my Tikka. I agree with your definition of a good fit except for hard bullets when .001” interference fit may be hard to seat. John

Attached Files

I find this thread very interesting since my favorite rifle and the loads for it have a lot in common with what is discussed here. It shoots best with designs similar to John Alexander's NOE 22780, but in .30 cal(311331, 311334, long nose/short body). I seat them with just a little more than the GC in the case. The throat is similar to what frnkeore suggests above, but to the extreme. It has very little freebore(.05"), but the leade is cut .6” long on purpose by the arsenal to safely chamber and shoot .311” bullets in a .308” bore. The cases don't have enough meat to make a stepped case as joeb33050 described in this chamber(I considered it though); so I only size the top half of the neck and expand with an M die to create the step. I may test putting a cannelure in some necks instead of sizing and expanding to create the step, or alter a Lee collet die to put the band there. Loaded this way the bands seal against the throat while the nose engraves just enough length to guide it, but not so much it is hard to chamber with a slightly oversize nose and/or hard alloy. I have considered testing BS vs. this method since it would be relatively easy in this rifle.

Attached Files

I'd like to add that I do nothing special to my cases. Neck size with a lee NS die only. No neck flare at all. Just seat the bullet after priming and adding powder. Just last evening I took 5 loaded rounds that I had loaded, measured the oal, then chambered each and remeasured them afterwards. None of my bullets were set back in the case after being chambered. All of the bullets showed marks from the lands. I guess I'm just lucky that my bullet fits so well. That said, I also shoot this bullet in 2 more rifles both 308 with factory chambers. One a Savage I rebarreled and the other a Howa 1500 with good results. Just my $.02

mrbill2

Attached Files

one reason that my so-far-fantasy ” 6mm super rook ” system works so good .. in my mind ...is that it is a heeled bullet, and can be pushed into it's tight throat by the case.

if you just drop the bullet into the chamber can't you just neck size a case down a bit and push the bullet in ? run a 30-06 neck into a 270 neck sizer die. i don't see a pressure problem with cast bullet loads. or put a brass rod into the 30-06 case and seat then put in the charged case.

or use a heeled bullet.

kenKen;I can't “just neck size a case down a bit and push the bullet in ? run a 30-06 neck into a 270 neck sizer die.” because of blow by. I bell the case mouth for every shot, that stops the blow by. The handle end of the Lyman #2 or pope re-de bells just enough. When I forget, if there's blow by, the result is visible on the target. Brass rod or wood dowel works fine for me with a plugged case.joe b.

Attached Files

joe ...by blow-back do you mean blow-back that turns the case necks black ?

or blow forward that gas cuts the cast bullet ? i thought that is what breech seating does for us ::: seals the grooves ... ( and of course doesn't leave the bullet floundering in mid air trying to find it's way into the barrel . ) .

wouldn't the same bullet that seals when seated in the case also seal when breech seated even further in when pushed by a case neck ?

thanks ken

Attached Files

joe ...by blow-back do you mean blow-back that turns the case necks black ?

or blow forward that gas cuts the cast bullet ? i thought that is what breech seating does for us ::: seals the grooves ... ( and of course doesn't leave the bullet floundering in mid air trying to find it's way into the barrel . ) .

wouldn't the same bullet that seals when seated in the case also seal when breech seated even further in when pushed by a case neck ?

thanks kenI MEANT THE GAS THAT GOES AROUND THE CASE MOUTH AND MAKES THE NECK BLACK, SOMETIMES DENTED.? Caps lock comes on by itself, is someone out there doing that?

Attached Files

joe --ok, i gotta work y learn ... the only breech seating i have done was on a stevens-pope, 32-40 ... used just an unsized case with a card wad ... don't remember black necks, even with mild loads of #80 . hey, maybe #80 is the answer !!

i do get black necks with even case seated bullets if the load is very mild ...

ken

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

John Carlson 22

-

linoww

17

linoww

17

-

Bud Hyett

15

Bud Hyett

15

-

drone 9

-

MP1886 7

-

beltfed 6

-

Lucky1 6

-

RicinYakima

5

RicinYakima

5

-

Eutectic

5

Eutectic

5

-

mashburn 4