Could you add anything to the conversation about gas checks effect on accuracy? Would the Pat Marlin gas check maker come into the conversation? Aluminum versus brass? Crimped vs not crimped? Do you seat the gas check prior to size and lube?

This is a carry over from the thread on the question asking if anyone did anything unique to uniform their bullet bases before lube and gas check. The conversation was last left as it drifted into the impact gas checks had on accuracy and small groups.

I'm neck deep sorting out bullet to bore fit on borerider bullets so I need another variable like gas checks and their willingness to say on the bullet in a square uniform manner. Before I lubed, sized and checked a hundred bullets from a new mold this weekend I first uniformed the bullet bases. They already looked perfect to me but some toddled a bit. After the sizing, lube, checking process I found some were back to wobbling again. That led to the subject of gas checks.

I need another variable to work with on cast accuracy like I need another hole in my head but my instincts tell me that if the base is not square with the bullet it isn't going to help me put all 5 shots through the same hole. So this morning I took the three gas checks styles I had on the shelf and used one of each onto the base of these same bullets from the new mold using the Lyman gas check seater sans lube and sizing.

The Sage had a rounded base, the Hornady was pretty good and the old Lyman (not crimped, before outsourcing from Hornady) sat the flattest. One snapshot like that means nothing but its like an itch I can't reach to scratch. Before I shoot this week I think I'll re-seat what I already have sized and lubed from the new mold using the Lyman gas check seater to bump and visually look at squareness.

There's no magic bullet to shooting cast accurately that hasn't been discovered by others decades ago. Everything I've stumbled across these past two years had been found and exposed many years ago. But a rookie has to wade in and get your hands dirty or you'll never appreciate the sanctification of shooting small groups.

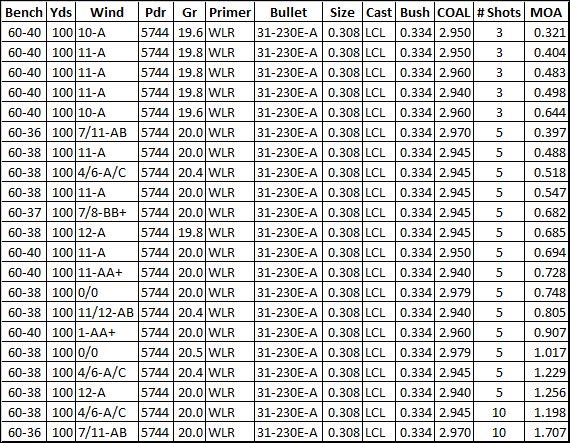

I'm pretty vocal about the shooter having to have solid bench equipment, bench practices and wind reading skills before you can get around to wringing another .200 out of an agg. I believe I have the platform. I believe if I can agg under .6 in load development I hope to be able to stay below 1 MOA in competition. This is with a production class Savage F10, all powder charges, all COAL's.

If the thread has any traction I'll post some of what others contributed on the previous thread. Thanks, Bill Cook.

A “Measured Response” is as effective as tongue lashing a stuck door.