Any efficiency professionals out there? How do you arrange your cast equipment? What's your work station set-up? I'm thinking ergonomics.

With me, I have my pot in front, then I turn to the left and knock off the sprue, then shift left again and open the mold onto a towel lined flat.

I use a Lee bottom pour pot. I'm thinking of adding something to rest the mold on under the spout when I open the valve to pour.

Just wondering if anyone has any tips or ideas to share.

Usually, my casting stuff stays in a bucket and I cobble up a work station in the garage out of stools and such. I'd like to make a small, dedicated work station that I could leave outside on the patio under the eaves of the house. Something I could cover up like the old roll top desks. But something that would be compact-ish and weather proof. I even thought about converting an old bbq grill. You see people putting them out on the curb. Those are made to stand out in the weather.

IDK. I'm brainstorming and asking for ideas. Thanks in advance.

Work station set-up

- 920 Views

- Last Post 01 November 2022

- Topic Is Solved

Attached Files

Wow. Nice. I recently picked up a Lee single stage press and Lee powder measure from a friend. I've mounted both to separate boards. I clamp them to a table in the basement, in front of the tv so I can process cases while watching a movie.

Attached Files

Well for the rest of my reloading- casting room. This bench is to the right around the corner from the casting bench.

I had just received a new Redding Big Boss which got mounted to the right of the other Redding. Had a RCBS Rock Chucker Supreme in the second position but wanted the same operating press. The RCBS press was great but just different enough to bother me.

The work bench is 3” gluelam beam on top of two roll around shop work bench’s with good drawer slides. The little mini tables in between the presses, are on dowels and can slide out and move to other locations at the bench.

a better picture of the removable mini tables. Also I used 1/2” steel plates which were threaded for 3/8” bolts for each different press. Just crank the bolts out and mount a different press.. Now that I have more space they are not needed.

This riser idea for the powder dispenser was originally from Ben on another Forum. When I saw a picture of his setup I just had to duplicate it. It allows the use of any dispenser with a 7/8” thread. I can quickly change from the Little Dandy to the UniFlo or my Lyman 55. Actually I had extra RCBS powder stands so each powder dispenser has its own stand which are changed out by two wing nuts. also in the first picture the bench mounted powder stand with the Lyman 55 has 1/4” wing nuts so any dispenser can be used there as well when using the single stage presses.

Moving further to the right is some book and ammo storage.

the door is a solid oak fire door surplus from a remodeled school. The trim around the jam is 1/8 steel flat strap to make a solid reinforced door that is hard to defeat.

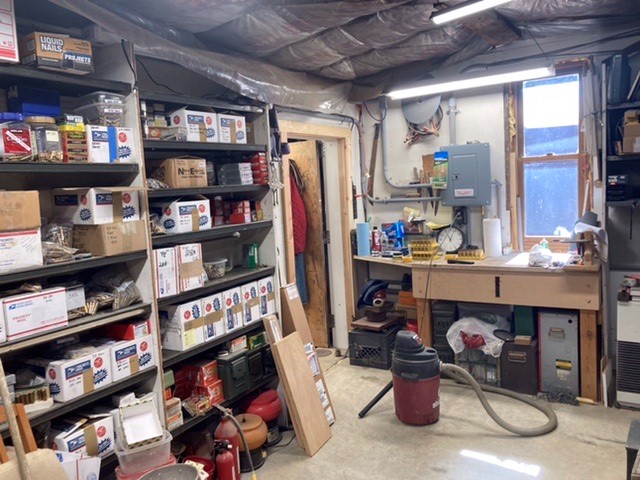

Outside in the garage for a cleaning work bench and more storage. I have a fan assembly that goes in the window for when I’m smelting lead into ingots. The shelves on the left is mainly brass storage.

Attached Files

Since I've been powder coating, the lubrisizer hasn't seen any use. May be getting rid of it. Also, I've developed a "proprietary" method of processing backstop metal. Those ingots and the boolits are made from metal that came from behind my club's pin table.

Attached Files

Yeah Max that looks good, manage the stuff up front.

I’m not to organized, well a better way to put it is I’m seasonally organized. That means that it has gotten out of hand and I’m usually just able to group items. Having just moved onto my new room a couple of years ago nothing has gone in that’s not useful to current reloading/casting.

I’ll post some pictures of the rest of the room, which suits me well. All nonessential reload supplies and a gun cleaning work bench are in the main garage.

When I did the move into the new room I went through everything. Found many duplicates of components and tools that I sold off a couple of years ago which was nice because of the shortage’s I was able to recoup some of my unnecessary spending over the years.

I believe in the KISS principle although it’s hard to keep up with when work and the Arctic demands your attention.

Attached Files

Here's my semi-permanent casting station, moved indoors. It's on the back porch. Like the rest of my reloading activities, I have to keep it neat. I like it better that way. It is so easy to accumulate excess garbage.

Here's my semi-permanent casting station, moved indoors. It's on the back porch. Like the rest of my reloading activities, I have to keep it neat. I like it better that way. It is so easy to accumulate excess garbage.

I recently bought a Lee 6 cavity mold to feed the 38's and 9mm's. With this arrangement, and a little creativity, I am able to process backstop metal into satisfactory boolits. Lets me save my stash of good lead for bigger and better things.

Attached Files

I put together a little larger loading, casting room a few years ago. I’ve rearranged the casting bench 3 times and believe the current arrangement might just be the last. It flows pretty efficiently.

Mold storage

26” mid tool boxes stack nicely with great drawers.

40” black mid box I had laying around made a great drawer for sizers, expanders and other tools. 2 Lee 20# pots and one RCBS all 3 hooked to PIDs. 2 lighted range hoods for ventilation, toaster oven for powder coating, hot plate on shelf above RCBS pot. The side bench needs more bracing.

Attached Files

All of my reloading is done with a Lee handpress. The handpress, dies, and other tools live in a plastic storage box under my bed. I have another box full of molds and a third with my bullets. My Lee 10lb pot stays in the garage on the back of the workbench with half gallon ice cream buckets (they have lids) with my different alloys in them. I usually cast in the garage with the doors open and I reload at the kitchen table. Someday when my kids are all grown I may have a more permanent setup. That will be a while, my youngest is six...

Attached Files

Hello Buttersdad,

There is nothing wrong in casting outside. When the weather is good, I roll my portable bench out under a big shade tree. The only time I cast inside is if the weather is inclement. Keep up the good work and enjoy.

Mashburn

David a. Cogburn

Attached Files

I don't have a permanent set up for my melting and casting. I too have a Lee bottom pour that I use with my set up. I use our patio table, (sorry no pics) and I have everything that is not affected by weather in a PVC storage box out by our shed. The furnace and all else that is weather sensitive I keep in the gun/reloading room and bring out for melting/casting sessions. But judging from the pics in this thread my set up isn't as extensive as some of yalls.

Attached Files

David, would you be able to post a picture of the information plate that’s on the vent blower you’re using. And is that just standard clothes drier flex pipe you’re venting with? Thanks Bill.

A “Measured Response” is as effective as tongue lashing a stuck door.

Attached Files

It is a tight fit, but it works for me. I figured this will be my last time setting up, so I planned for weeks, making scale drawings to utilize every inch of space. I can't remember if I posted other photos before, but I will now showing the other end of my reloading bench. Those photos only show my casting side of the bench.

David Reiss - NRA Life Member & PSC Range Member Retired Police Firearms Instructor/Armorer

-Services: Wars Fought, Uprisings Quelled, Bars Emptied, Revolutions Started, Tigers Tamed, Assassinations Plotted, Women Seduced, Governments Run, Gun Appraisals, Lost Treasure Found.

- Also deal in: Land, Banjos, Nails, Firearms, Manure, Fly Swatters, Used Cars, Whisky, Racing Forms, Rare Antiquities, Lead, Used Keyboard Keys, Good Dogs, Pith Helmets & Zulu Headdresses. .

Attached Files

David

II looks like you are getting maximum use out of a very small highly organized space. Things have to be well organized and kept that way it such a space, and your workshop certainly appears to be so, good job.

From 1976-1993 I did my reloading in a big walk-in closet under a stair way. My reloading bench was on one wall (a very narrow bench I might add) and a rifle rack on the other wall. Needless to say, it had to be kept in very good order. If I had as much reloading equipment as I do now, I wouldn't have been able to do it. I built on to the house in 93 and built a large reloading room in the new addiition. After 5 years of use, I sold the house and bought another. But with the move, I now have two shops,It looks like you did a lot of planning or trial and error when you set your casting shed up. Good job.

Mashburn

David a. Cogburn

Attached Files

This is my current, outdoor set-up. Like I said, its mobile. It fits in the bucket.

I'm working on a permanent station on the back porch. Got the fan in the window. Pics to follow soon.

I cast, then swing left to knock off the sprue, then turn further left to drop the boolits.

Attached Files

Max503 posted "Something I could cover up like the old roll top desks. But something that would be compact-ish and weather proof. I even thought about converting an old bbq grill."

An old Weber Silver, the original hooded BBQ grill from early 2000s would be ideal.

John - New Zealand

Attached Files

I set my Lee pot on my steel weld table with a fume hood that is at a comfortable height to use while sitting down, but is tall enough to have a good view of the spout, and I do use a chunk of steel to support the weight of the mold under the spout; handy on those 6 cavity muscle wreckers. Under the lead pot is a cheap, large, sheet metal cookie sheet. I drop the sprues directly on the cookie sheet and have an 8x8 cake pan with old canvas shot bags in it to my left at about 10 o'clock that the bullets are dropped into. When the sprues pile up, they are scooped up off the cookie sheet and dropped back into the pot and by that time I'm ready for a break anyway. The cookie sheet keeps most of the "fines" and mess contained.

I like that cookie sheet idea.

Attached Files

Offering the following to provoke thought as the amuint of cast bullets shot each year by two of us requires a semi-production line approach. Added to this is using two meltng pots for two differnt alloys. Built a reloading shed that was too narrrow (seven by twelve) and now have built one that is too wide (eight by fourteen). The thought was to set up all the melting pots, lubri-sizers, presses,in a line to eliminate the all- consuming setup time. This has worked,

The first is seven feet wide and with benches on both sides, Alice and I were continually bumping into each other when reloading. The second is ten feet wide with benches on both sides. Alice and I now have plenty of room. However, I'll need special handling permits to haul it when I move.

Therefore, were I to build another, it woud be eight feet wide by twenty feet long with benches on one side and across the back plus shelves and racks for storage on the backsjde wall. Benches on each wall is good, but a longer shed with one bench and ready stoage on the wall behind is a better concept.

Farm boy from Illinois, living in the magical Pacific Northwest

Attached Files

I set my Lee pot on my steel weld table with a fume hood that is at a comfortable height to use while sitting down, but is tall enough to have a good view of the spout, and I do use a chunk of steel to support the weight of the mold under the spout; handy on those 6 cavity muscle wreckers. Under the lead pot is a cheap, large, sheet metal cookie sheet. I drop the sprues directly on the cookie sheet and have an 8x8 cake pan with old canvas shot bags in it to my left at about 10 o'clock that the bullets are dropped into. When the sprues pile up, they are scooped up off the cookie sheet and dropped back into the pot and by that time I'm ready for a break anyway. The cookie sheet keeps most of the "fines" and mess contained.

Attached Files

Here is my multi purpose play space. My combination welding, blacksmithing and bullet casting area. Soon to add baking of bullet powder coatings also. If I have a welding project on the table, I have a steel top cart on wheels I can roll under the 16' wide exhaust hood. This garage is at the bottom of my 1/4 mile long driveway, so no fumes in the house for the wife to complain about. Also, I like to keep as much flammables as possible away from stuff that can catch them on fire!

Wayne

Attached Files

First of all, I' don't resemble an efficiency expert. Here is my casting set up. I purchased one of the little roll around carts from the big boat store (harbor freight). The top of it hinges up and there is a storage area beneath the lid, it has four drawers and a big area underneath with a bottom for a large shelf. I cut a piece of 3/4 inch plywood that is wider and longer than the metal top. I bolted this plywood to the top of the cart. You can still lift the lid to the storage compartment below. When I cast, I set my hot plate (to warm my molds up) on the left side, my bottom pour pot in the center and lay my pad for the bullets to drop on, to the right, I have enough room to drop the cut off sprues right in front of to the right whatever is the most convenient, You have all of the drawers for storage of tools, molds and such, It has 4 sturdy castors, all of which can be locked. With these wheels I can roll it around to anyplace I prefer to cast. I normally raise an over- head door and roll the cart up to the edge of the slab, put a fan behind me and have fun.I keep a supply of cut off blocks (2x4 1/4 and such) to build a rest for my molds to set on while pouring. I set on a wood bar stool that I bought at Wal-Mart years ago and is just the right height. When the weather is nice, I sometimes roll this rig outside, beneath a big shade tree to do my casting. When not in use I can store the lead pot, hot plate and my toaster oven, that I use for powder coating on the large bottom shelf, It also makes a nice little roll around work bench. I also use it to set my vibratory case cleaner on when I'm cleaning cases. My problem is, when I need to get something out of the top storage compartment, I usually have stuff setting on the top and I have to clean it off before I can open it,

Mashburn

David a. Cogburn

Attached Files

Here's my set up. My PID is under the stand holding up the pot. This gets the pot up high enough for me to see what I am doing. I use a long leather apron to keep the lead of me. the sprue is cut on the left and bullets dropped onto soft an angled cloth so that the bullets roll out of the way for the next drop. It works great for me.

David Reiss - NRA Life Member & PSC Range Member Retired Police Firearms Instructor/Armorer

-Services: Wars Fought, Uprisings Quelled, Bars Emptied, Revolutions Started, Tigers Tamed, Assassinations Plotted, Women Seduced, Governments Run, Gun Appraisals, Lost Treasure Found.

- Also deal in: Land, Banjos, Nails, Firearms, Manure, Fly Swatters, Used Cars, Whisky, Racing Forms, Rare Antiquities, Lead, Used Keyboard Keys, Good Dogs, Pith Helmets & Zulu Headdresses. .

Attached Files

- Liked by

-

-

-

-

- and 1 others

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

jeff houck

20

jeff houck

20

-

Aaron

15

Aaron

15

-

Wilderness

14

Wilderness

14

-

Tom Acheson

14

Tom Acheson

14

-

John Carlson 13

-

sghart3578 10

-

Spindrift

5

Spindrift

5

-

alphabrass

5

alphabrass

5

-

SkinnerD 5

-

MP1886 3