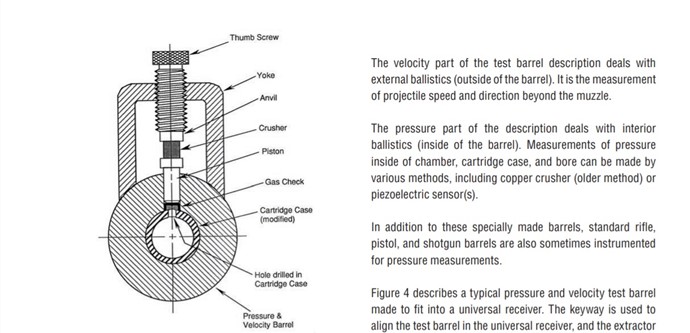

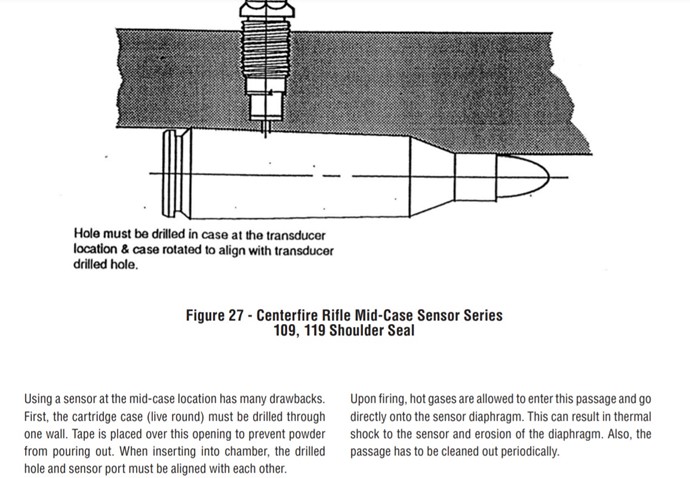

Yes, it is true there is an “offset” with strain gauge measurements. There is also an offset with every other type of pressure measurement systems for measuring chambering pressure. Those offsets account for the pressure required to expand the case, to register any measurement on any device. Why? Because we do not measure the pressure directly. There is no measurement system that measures inside the cartridge. We measure the pressure through secondary means just as we do many other things, the speedometer on your vehicle for instance.

As I stated previously, “A cast bullet, even a "hard" cast bullet, is much softer than a jacketed bullet. The pressure needed to swage down and engrave the lands into the bullet is much less. That swaging down and land engraving happens very early, at the beginning, of the pressure rise. It seemingly, so far at least, has little if any measurable effect in the pressure or pressure curve with normally sized cast bullets that are not larger than the chambers throat.”

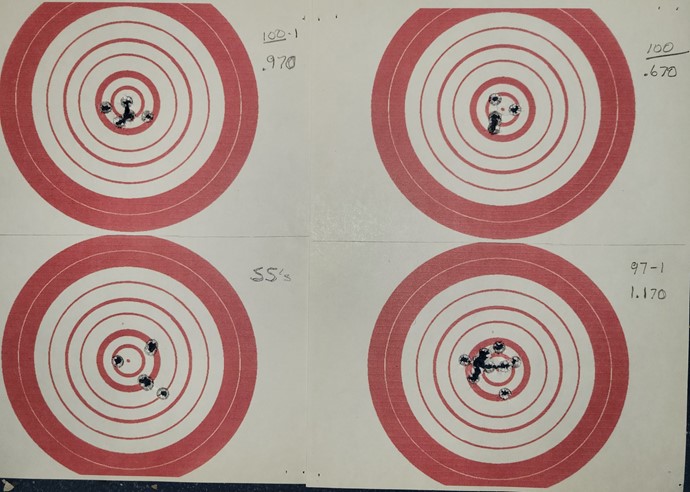

If there was a measurable increase in pressure it would manifest itself in the rise to peak pressure or the time/pressure curve (trace) and the time in milliseconds of that rise to peak pressure. So far, again as previously stated, there has been no indication of that with cast bullets when seated off the leade or into the leade. However, gearnasher states; “The pressure curve will be advanced very slightly and peak pressure increased a few hundred to a couple thousand pounds by a hard jam into the lands,”. There is no indication in all of my pressure measurements (thousands of different test loads of multiple cartridges) that such occurs. It did not occur when specifically tested for such.

Now to give gearnasher his due, it is well documented that a pressure increase can very well occur with jacketed bullets because a jacketed bullet does, in fact, require considerably mor pressure to engrave into the rifling than does any cast bullet. That has, indeed, been demonstrated, tested and measured by many ballisticians. I have measured that effect on pressure also.

Gearnasher’s statement of “this has been well documented by ballisticians throughout history. 5.56x45 NATO fired in a .223 winchester chamber, anyone? Is misleading at best and incorrect at face value. There is no 223 winchester. I’ll assume he meant 223 Remington(?) to correct the incorrect part.

Where his statement is misleading is the half truth. One can shoot all the M193 equivalent military ammunition in .223 Remington chambers with no adverse increase in chamber pressure from firing in that chamber. M193 will probably give a higher pressure simply because it was loaded to give that higher pressure. That has “been well documented by ballisticians throughout history”, at least throughout the history of the 223/5.56 cartridge. However, if one fire SS109 or M855 (Green Tip) in a standard SAAMI spec 223 Remington chamber the bullet may jam into the leade and a subsequent increase in the intended chamber pressure can result. It does not always occur but sometimes it does. The Army’s manual states one can fire M855 in older M16A1 chambers, with the only adverse effect being a lack of accuracy due to the 12” twist barrel. No increase in pressure just poor or non existent accuracy.

My conclusion of, ‘It seemingly, so far at least, has little if any measurable effect in the pressure or pressure curve with normally sized cast bullets that are not larger than the chambers throat.” Is neither myopic nor false. My conclusion is based on factual testing, not internet suppositions.

LMG

Concealment is not cover.........

.jpg?width=50&crop=0,0,50,50)