gp: if you send me a sketch of what gadget you think will work i will be glad to turn one out for you... even if it needs an immediate improvement, maybe it will be a start on something . supposed to get above freezing in my shop next week.

i have been making fully threaded 7/8-14 sizer bodies but now am playing with the great idea from ou of using the lee $17 case belling die body ... it occurred to me that you also wind up with a bonus case belling die ... ha ... duh !! my goal is to keep tinker costs under $40 for a simple body and nose sizer . an unknown right now is :: is simple good enough ?? ... gadgets are neat but they also should do something useful .

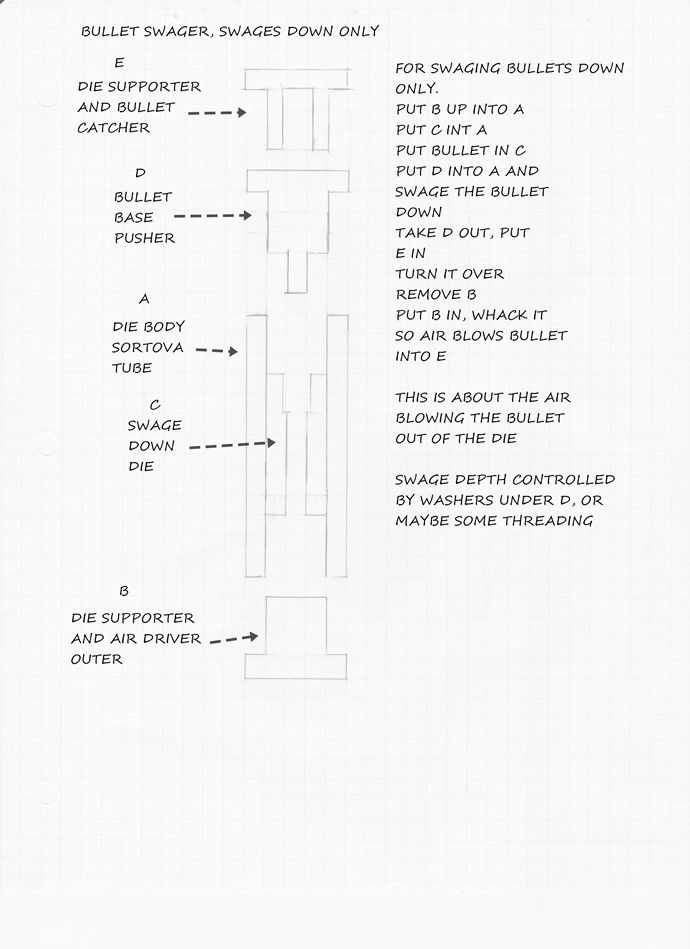

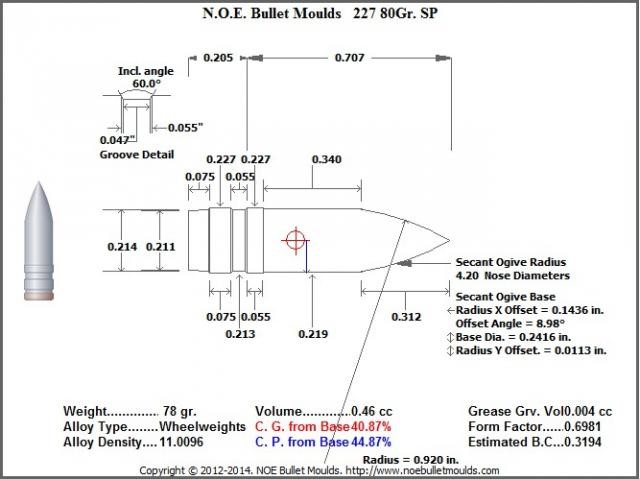

here is my philosophy of a simple die: first, the ultimate would be a fully forming swaging die ... this is not quite that .. because of complexities of controlling the nose shape and lead bleed-by .... so to keep this simple, the first goal is of sizing the groove dia. bands, square the base, and size the nose ..... all diameters a straight cylinder . thus leaving the nose ogive pretty much as cast, errors and all . what might save us is that errors in the nose might not be too important ... at least at the 1.5 moa ” i ” would be very happy with ... as a start .

everybodies' input is welcome ... the goal is that anybody with a hobby lathe could make a simple workable sizing system . it is sorting out except the design of the nose/knockout punch ( as usual ) . i think of this as a joint project and anybody please comment freely ... especially those who can point out all the shortcomings that i have failed to recognize . ( g ) .

here is some interesting things about the die housing :: it has a captive chamber about 5/8 in id diameter with a internal length of 1.4 inches . so the sizing insert if fully enclosed can slide in that space. the die has a 3/8 od threaded adjust screw that stops the upward travel of the sliding insert.

ken