Paul Pollard

posted this

22 November 2021

John,

Thanks for starting this thread. In discussions with Bob Birmley, he said that a case would shoot well for a time, then stop shooting. He would discard that case and start a new one. Some of this is mentioned in FS 250 and 251, "On the Road to Records." I tried his method several years ago and could find nothing that worked as he said, so I gave up on trying to find the perfect cases.

There was a recent question on Benchrest Central about Creighton Audette's being a benchrest shooter. Speedy Gonzales posted an article from a 1986 Precision Shooting magazine by Audette. He showed targets shot a long range which were with cases with less than .002" wall thickness variation which were much better than the cases which were .004" wall thickness variation. His contention was that uneven wall thickness mattered. He also suggested that the thin part of the case should be oriented at one of the bolt lugs.

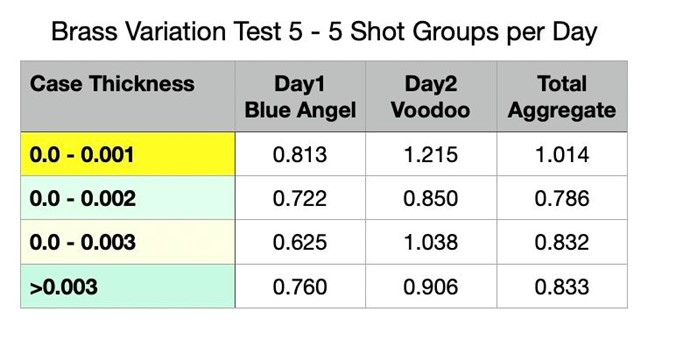

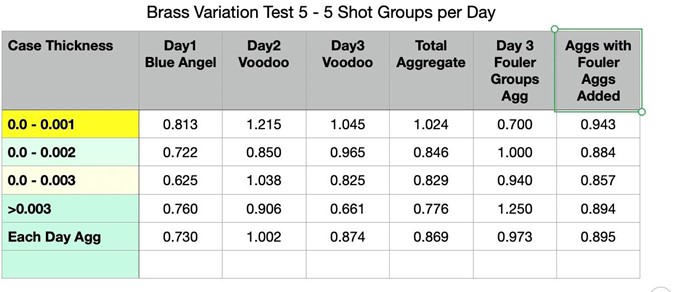

That made me wonder if it mattered in 100 and 200 yard cast bullet shooting. I made a fixture to measure case wall thickness. My 300 Lapua 220 Russian cases have been used since 2008 and have about 70 shots on each one. I ran these over my wall thickness gage and separated them into lots of .001, .002, .003 and over .003 thickness.

One other thing that floats around is that fireforming loads for jacketed bullets are somehow more accurate. I guess it's only anecdotal evidence. I fireformed 15 new cases and checked the case thickness. Most were within .001 on wall thickness. The necks on these all measured .014". If they would fit with a bullet seated, I wouldn't even turn these necks.

On measuring the often-shot cases, it felt like the internal probe was running on a gravel road. I borrowed an ultrasonic cleaner to clean the cases outside and inside, to try eliminating the gravel. No luck. They still felt rough and the over .003 variation persisted in these cases. The new cases did not feel rough when measuring.

That's as far as I've gotten so far. I'm pretty sure that John will accuse me of jousting with windmills, but I've done it before. Some people also say that orienting a case does nothing, but Mike Mohler did, and a few of his records still stand.

It may take some time to run this test and I'll report back.

.jpg?width=50&crop=0,0,50,50)