Could anyone explain the pros and cons for the amount of bearing surface a bullet carries?

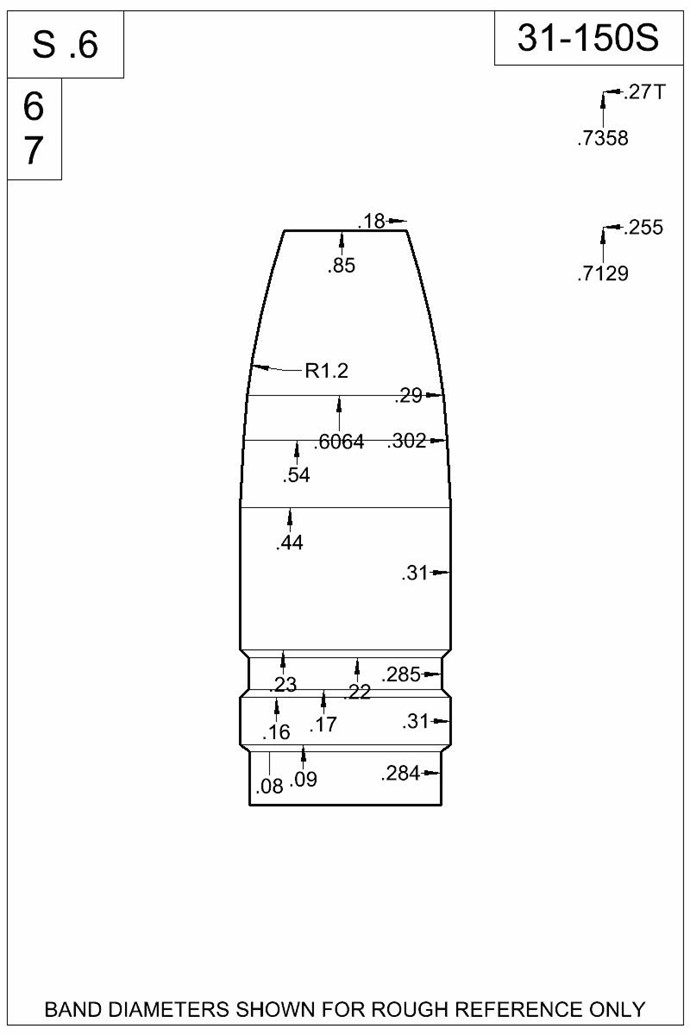

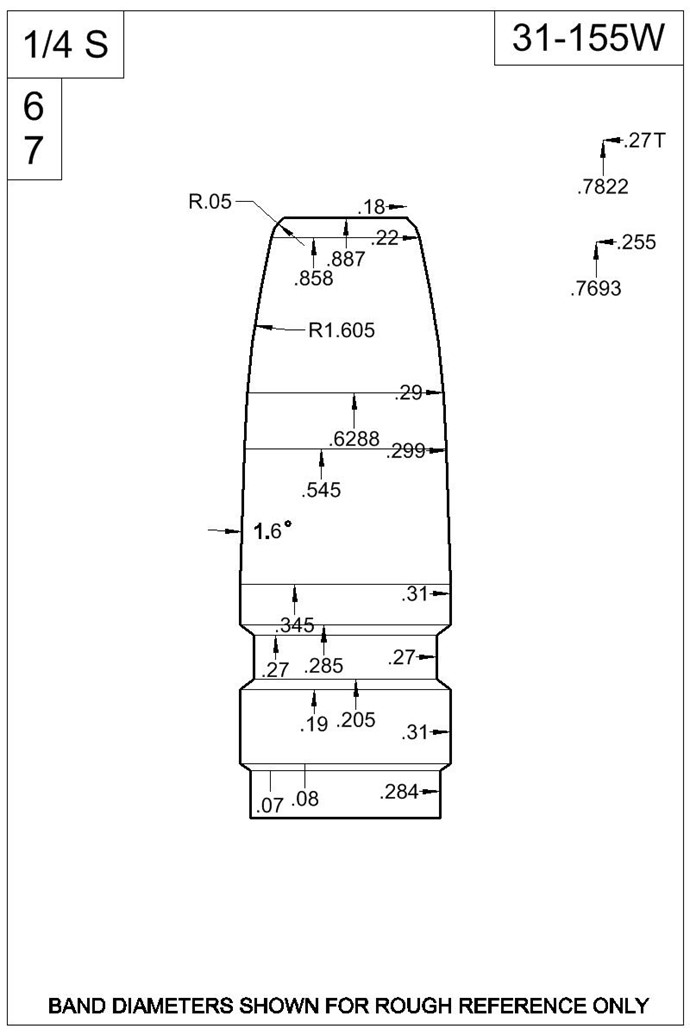

Below are two molds from Accurate. Unless I am reading this wrong )always the chance, I'm not the sharpest crayon in the box) the 31-150S has a bearing surface of about 55% of the bullets entire length. The 31-155W has a bearing surface of about 28%. The bearing surface includes the required gas check on the shank, lube band and the non tapered mose of the bullet. These numbers skip over the changes made by the sizing process.

So my question is how does the bearing surface effect bullet flight?

I'll add that the 155W has a 1.6 degree taper from .345 to .545" of its over all length where as the 15S has a straight body from .230 to .440. In addition the 150S has a bullet tip radius of 1.2 degrees and the 155W has a tip radius of 1.6 with a second approaching metplat radius of .05 degrees. Is the taper and radius differences fashion design or does it have a purpose.

Ihave a lot to learn about cast bullet accuracy. Thanks, Bill.

A “Measured Response” is as effective as tongue lashing a stuck door.