onondaga

posted this

22 April 2017

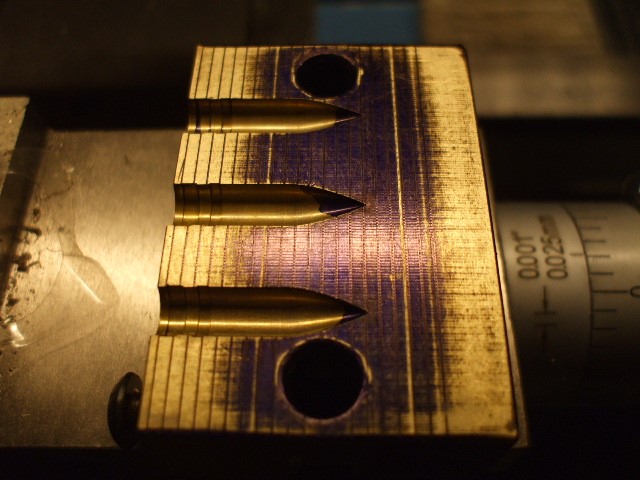

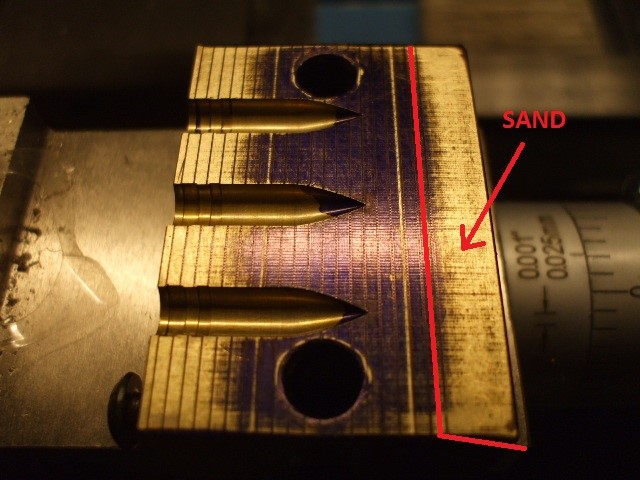

OU812

Your method is so different than mine and your ink marks aren't as conclusive because you use so much ink and it looks like you did it wet with ink. Try it like I do.

1) clean all ink off.

2) put mold block handles back on blocks.

3) open handles and put ink lightly on one block face and allow to dry.

4) While squeezing handles with light hand pressure tap the handle extension bar in the mold blocks lightly with a plastic or leather mallet.

5) open handles and look to see how the ink has been disturbed with optical magnification 6-10x

6) the pre-contacting areas will be indicated by disturbed ink

7) reduce the indicated areas

8) Clean off ink and repeat steps 3-7 until you get even full surface contact of the mold halves. Cleaning each time before applying new ink is necessary for true readings.

It is a very methodical thing to do. If you have a friend that is an old machinist, ask him to demonstrate “spotting in with indicator ink” He has done it thousands of times.

There is a number of machinists on this forum, I hope one will chime in too.

You have a very small amount of metal to remove, likely .001 and it is delicate. If you don't have the hands for this send it back to the maker with YOUR handles and ink marks.

Gary