April 2019 update!

April 2019 update!

So I took this "Designated Cast Bullet AR15" to shoot squirrels a couple of weeks ago. I had already turned the barrel down to .600" straight contour in front of the .750" gas port to the muzzle and re-parkerized it. I had not replaced the round floating forearm since building the rifle and also had the carbine adjustable stock on it. I wasn't happy with feel of the rifle and frankly the round floating forearm wasn't very stable so I ended up shooting my Browning A-bolt the entire week of squirrel shooting.

I ended up shooting about 1200 rounds for the week and figure about 50% hits out to 300+ yards. 100% at 50; 80% at 100; 50% at 150-200; and about 20% at over 200 yards. Average was about 50%. This gives me a kill rate at about 600 squirrels in 5 days of shooting. 2 days were raining and overcast...no squirrels to speak of...

When I got home I ordered and A1A2 solid stock and a streamlined light weight forearm with a flat base that is only 1.5" diameter. (removed the 2.0" round one...it's for sale). Because the A1/A2 stock tube is longer than the carbine length stock tube I decided to use an stock carbine length spring and the weightless carbine buffer I used before. They worked flawlessly with 100% reliability, extraction and bolt hold open on the last round. The lightweight streamlined gas port is adjusted fully open without enlarging the gas hole in the custom pistol ported 7.5" ported, 20" McGowan bbl.

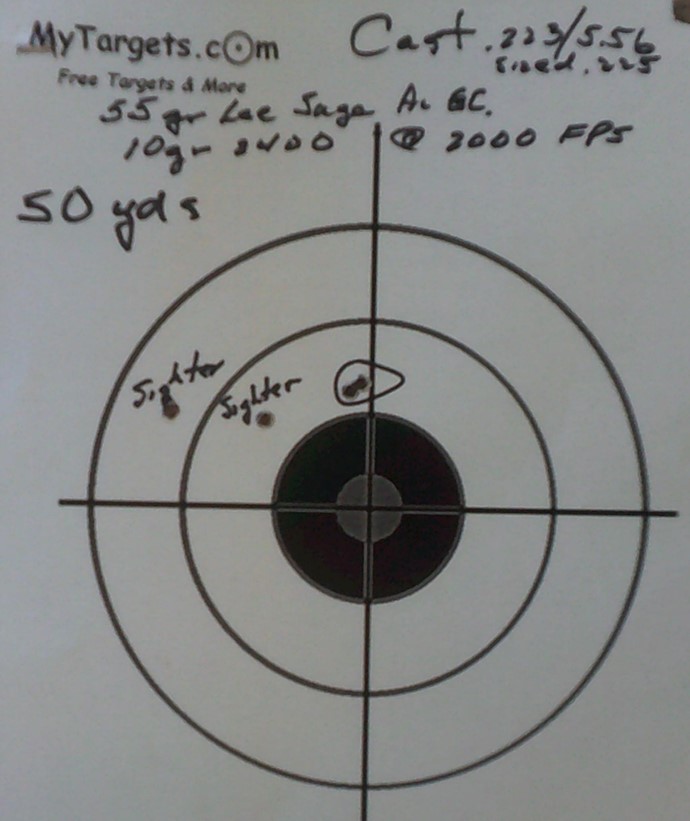

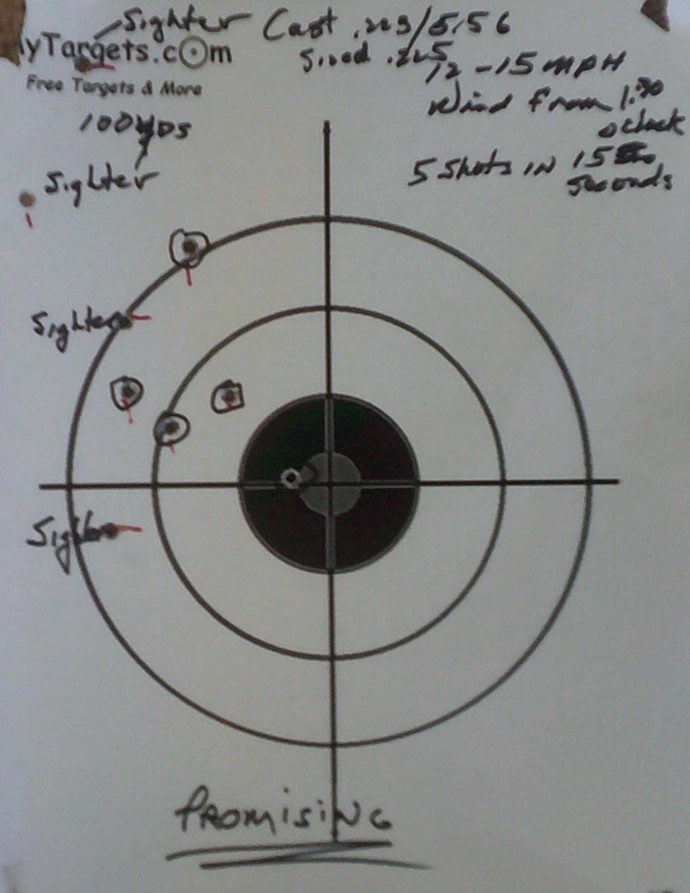

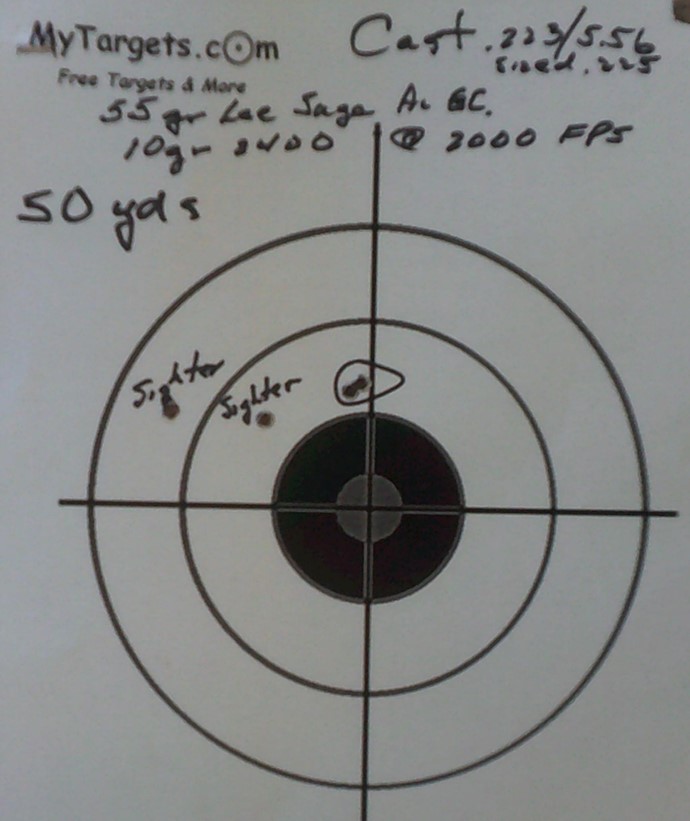

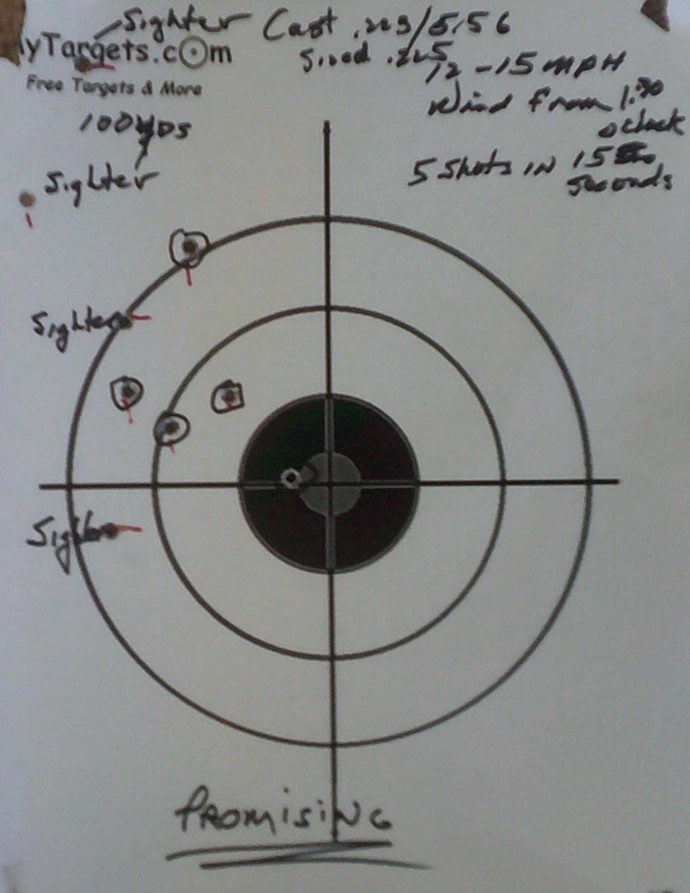

Today, I went out to my BLM private range to test and sight in a bit more. Wind was gusting at 12-15 mph from about 1:00 o'clock. Not prime shooting! I'm extremely excited about the potential of the rifle now. I will post a pic of the rifle and 2 targets I shot today. 50 yards and 100 yards. Not stellar because of the wind but the potential is there. The rifle is much more stable and comfortable now. I do see me shooting more rounds than my bolt guns with reloads after 20-30 rounds instead of every 4 rounds or between each shot.

I'll be using this AR when I go back on my next squirrel shoot in late June after the first alfalfa cutting/baling. I figure to clean the carbon fouling after every 100 rounds or as needed when accuracy falls off. That's what I do with my bolt rifles. No leading in any of them.

Now to get back to casting, sizing/lubing, brass prep and loading. Thank God I'm using a LEE Pro1000.

April 2019 update!

April 2019 update!