Hi out there. I’m looking for some help with a very specific question and I have a lot of background, so my question is going to be fairly lengthy. In summary, I’m looking for why my bullets seem to be keyholing, and what can I do about it. Now the background: The firearm I’m using is a Steyr-Mannlicher M1895. It is chambered in the original 8x50R and still has the original 30” barrel. The bore looks fairly good, although it does show some minor pitting. Nevertheless, the muzzle end seems ok since a vintage military bullet only goes in part way.

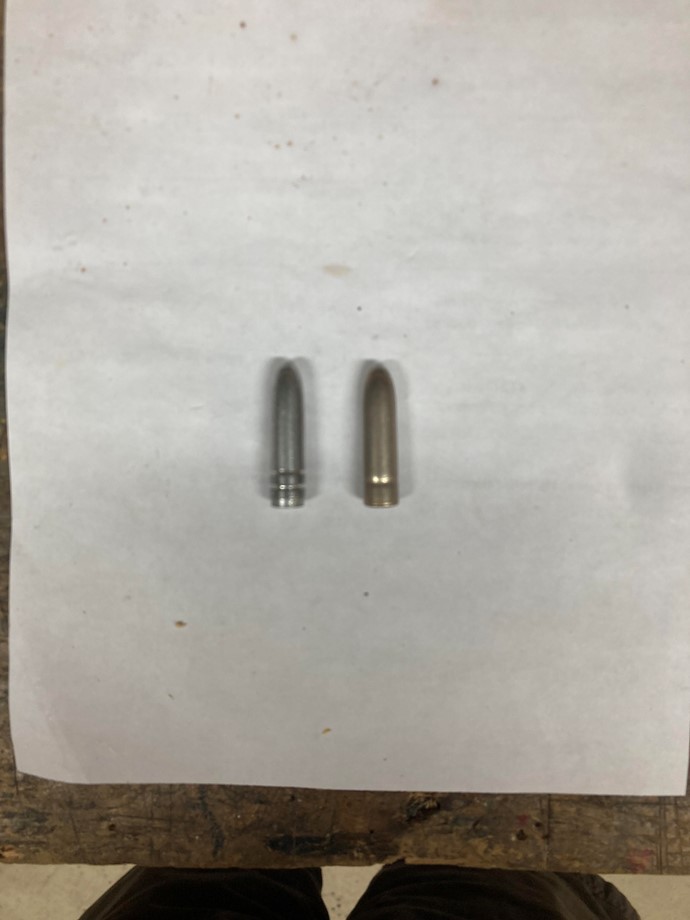

First, what ammo doesn’t keyhole? I have about 40 rounds of vintage military ammo for this rifle. The headstamp shows the Bulgarian lion and indicates that they’re from 1936. The bullet is a steel-jacketed round nose and weighs in at 244 grains. There’s a cannelure near the base of the bullet into which the case mouth is crimped. I don’t know what weight or type of powder is inside. I recently went to the range and shot a 4-5” group (5 shots) at 50 yards. The hits were about 12” above the point of aim, even though I had the rear sight set as low it could go (300 Schritt). No keyholing.

Second, I have other ammo that I purchased from Gad Custom Cartridges. These are reloads made from reformed PPU 8x56R cases and have what appears to be 205 gr spire point bullets. Once again, I don’t know the weight or type of powder used. These seem to print pretty close to the point of aim using the same rear sight setting. Similar group size but no keyholing.

I measured the diameter of both of these bullets (i.e., the vintage military and the reloads) and they both measure 0.323”.

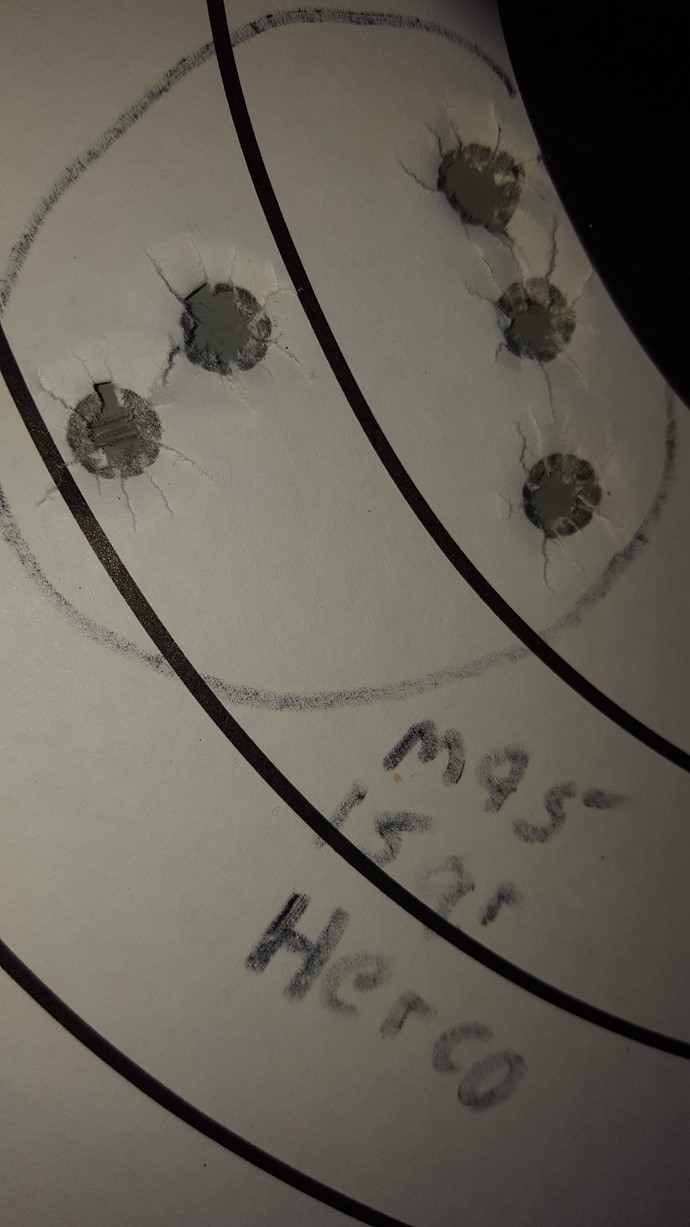

OK, now the problem. I made some reloads of my own. The cases are leftover vintage military (1936) that I decapped (Berdan) and reamed out the primer pockets to fit CCI 250 Magnum large rifle primers (I was not able to find any CCI 200 primers anywhere). The cases were full-length resized and I guessed at a charge of 45 grains of IMR-3031. The bullets are ones that I cast myself from a Lyman 323378 mould, using homemade #2 alloy (hardness measures 15) and 8mm gas checks. The bullets were sized to 0.323” (i.e., to match the other bullets that I described above). When I shot these at the range, I could barely find the holes until I saw a couple that were quite far away from the point of aim and totally keyholed.

OK, now, let’s talk about the diameter of the bullets, because this is a very common cause of keyholing. From what I’m able to read, the bore of these old M95 Mannlichers is 0.329 or 0.330”. I have read that even though the original 244 grain bullets measured 0.323” they were expected to obdurate during the firing process, thereby grabbing the grooves and stabilizing the trajectory. I have no way of knowing how much, if any, obduration either my vintage military or my Gad Custom reloads experienced. All I know is that for those two cartridge types, there was no keyholing. I haven’t yet had a chance to slug my bore.

So, even though a very common cause of keyholing is bullets that are too small for the bore, this didn’t happen with 0.323” bullets in the first two cases, only in my reloads.

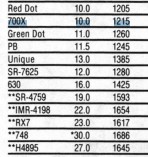

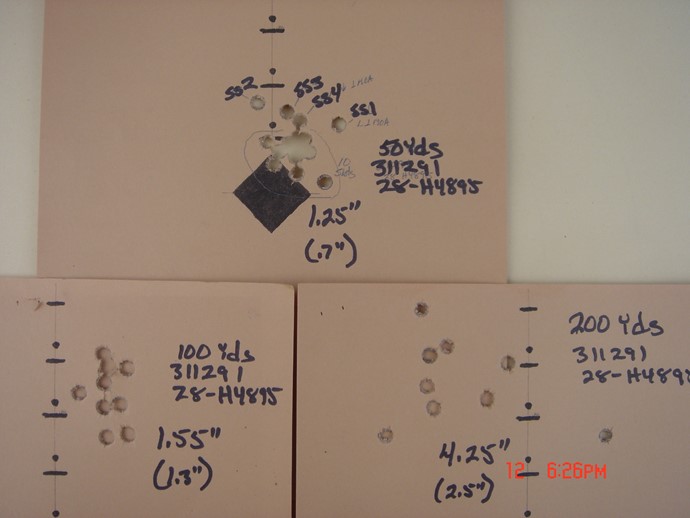

So, my next question, is it possible that my own reloads are overcharged and forcing the bullet down the bore too fast for it to obdurate and grab the grooves? Does anyone have any powder data for this cartridge with a 240 grain long round nose bullet?

.jpg?width=690&upscale=false)