Two breechseaters, Russ Weber and Ken Meyer, which work well are what I have. Currently shooting 25:1 alloy, but going to 20:1 before the next match. I have experimented with 20:1, this alloy is about as hard as you can easily breech-seat.

Working with two CPA Stevens (one likes AA 4100 and the other likes #9), the chambers are close enough that either breech-seater will work in either rifle. I use the CPA plugged case after lightly seating with the the Meyer to assure uniform seating. I am not handy enough to toss a bullet into the chamber and then use only the plugged case.

With the passing of Russ Weber, I looked at the tool for manufacture. it is complicated and I do not know how he made it so cheaply considering time investment and tooling. However, if there is a way to investment cast the main body with tooling points to drill and ream the central bore, this could lower the cost considerably. The locking lug into the action dimension could be cast the longest common dimension and then be trimmed to the needed length for each action series. The other feature that could be changed for ease of manufacture is eliminate the screw threads that hold the case and use a tight slip fit.

There is an article in the latest ASSRA Journal on breech-seater tools and their history.

Farm boy from Illinois, living in the magical Pacific Northwest

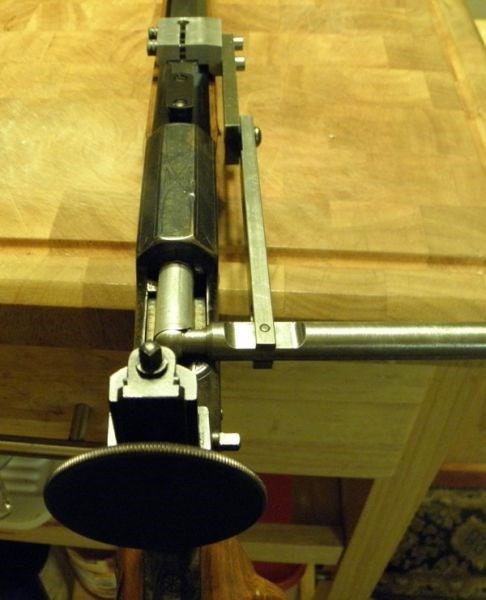

a seater attachment for RB that is also a scope mount

a seater attachment for RB that is also a scope mount