Disclaimer; I've been shooting cast for 30 years but it's only been in the past two years that I focused on cast accuracy. In short I'm not smart enough to eat at the big people table when it comes to cast accuracy. But to a degree I'm smart enough to listen to what they say and I do catch the occasional cuss word.

Two years ago I would have flunked the test for the definition of bore rider vs bearing surface. Even today there may be a dispute about where bore riders design ends and bearing surface begins. But I hope we can start out with the expectation that bore riders must make contact with the lands. between 20/1 and Linotype are a couple of variables that makes this a pointless to argue over.

Borerider accuracy: Pieces of the puzzle started to fall together when Covid hit and I started to spend a lot of time at the bench. After a through weeding out of my gun safe I wound up with a new Savage 10F in .308. That led to a second 10F in .308. That was the start of the rabbit hole that had me hooked on the number of variables that must be controlled for accuracy. Not many will argue that cast accuracy is significantly tougher to achieve than jacketed accuracy. And although I'm talking about bore riders I believe the majority of folks will agree that a properly fitted tapered design will be more accurate then a borerider.

From Ken

i have always thought that bore riders are a good way to get down to about 1 moa, but full groove diameters necessary to get much under that

But I hope to have this thread focus on boreriders because it is user friendly for a number of shooters. I think tapered design is better but there's a steep learning curve to understanding bullet to throat fit.

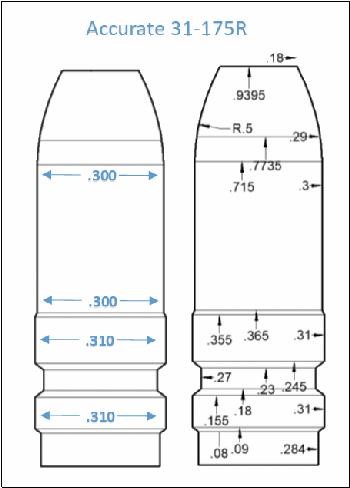

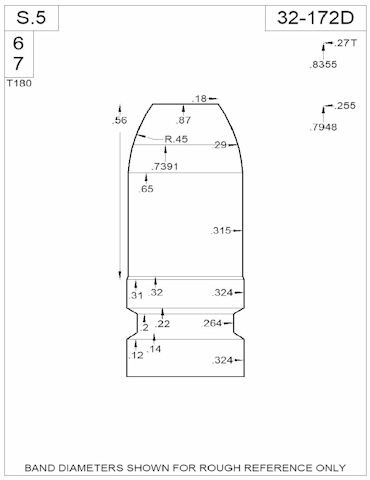

A couple years ago the only competitive mold I had was a Lyman 311299. This is a borerider design. I may be way off base but it strikes me that the freebore design is a good middle of the road choice for a production rifle. As long as the freebore can take .310 sized shanks you can get the gas check at the bottom of the neck and you should be reasonably accurate. I believe the freebore design started with the Springfield four groove barrel way back when but I'm not a historian, ballistics expert or a machinist so others know a lot more than me.

Unique to the .308 rig I'm working with is that the bore is oversized. As best I can tell the bore on this barrel is ~ .3014. I've tried to measure bore (tip to tip lands) every way come Sunday and its hard as heck for me to get an actual measurement on the bore. I've tried measuring, using a small bore gauge, pound cast, chamber side bullet tap and even reverse engineering guesstimate to see where the lands contact the nose (non bore riding bullet) but everything boiled down to an estimated ~ .3014 bore.

My two cavity Lyman 311299 drops similar bullets with a ~ .2985 to ~ .3004 nose. The dimensions differ through the length of the nose but you get the picture. With some support from someone on the forum I was hand fed the how to beagle a mold. I haven't received my certification yet on Beagling but I've come far enough that I can compare nose to lands tolerance as an independent variable to cast accuracy.

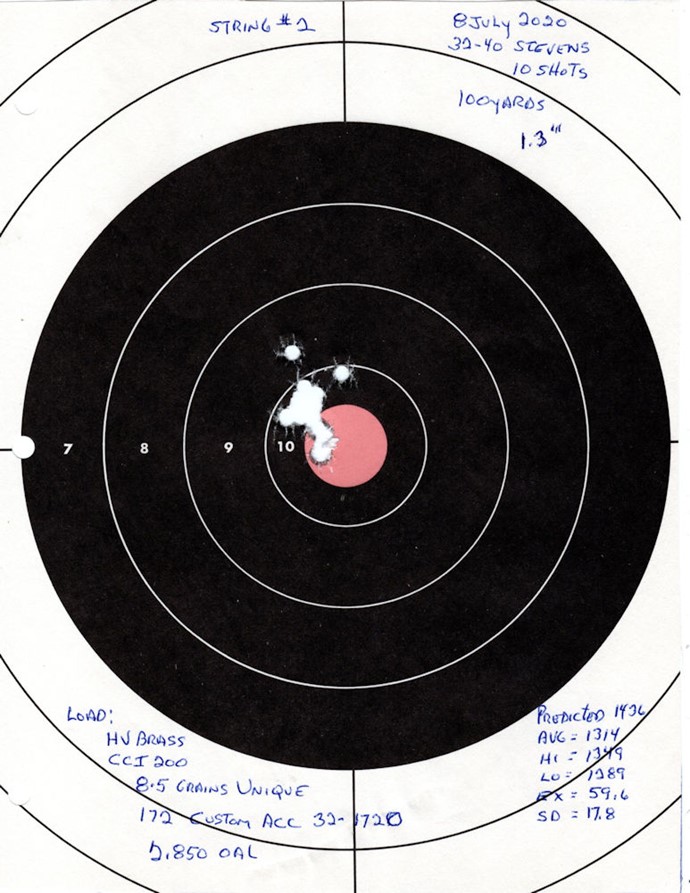

Results: Four five shot groups with a proven load were shot side by side. Lyman 311299 weighted to the .1 grain, #2 Lyman, 23.0g H4198 ~ 1760fps, Fed 210 primers, Can Bl lube, .335 bushing, sized .311.

- ~ .2985 to .3004 nose diameter aggregate 2.285" MOA

- ~ .3010 to .3014 nose diameter / aggregate of 1.453" MOA

I may be the last person on this forum to figure this out but I believe that bore rider tolerance is as critical to accuracy as olgive to lands is with jacketed bullets. Where jacketed accuracy is found by starting on jam (.001 to .002 of sticking on a new barrel) and then backing off in increments of .002/,003; optimum bore rider accuracy may be found with nose to land tolerance of +/- .00025. And although alloy (#2 Lyman vs Linotype) gives us a variable to work with, the alloy source is critical.

OU812's design for sizing the nose seems like a big step towards to finding that sweet spot. Beagling is another choice. There is always the alloy and of course you have Tom who can cut anything you need for bore dimensions. A custom mold and playing with the alloy can give you +/- .00025 to work with. Maybe the tolerance isn't as tight as I think. Maybe .0005 impression of the lands on the nose is good enough. Maybe .00075" is right. Then on top of that throw in the typical BS / SS (Barrel Specific / Shooter Specific) factor and you have an interesting puzzle.

Unique to my situation is that I have a tight freebore. Instead of the SAAMI .310 I had ~ .3085 on each barrel. My guess is that this bullet will never be competitive in the barrel I'm putting it through. That's why the bullets are seated down to the shoulder. Thanks, Bill.

Here is the difference between the .~.300 vs the ~.3014 nose on the bore of my rifle.

A “Measured Response” is as effective as tongue lashing a stuck door.