John Ardito wrote about long throat length not seeming to matter in the recent TFS. Somewhere, I think on this forum, I read the same comment from another trustworthy source.

Does anyone know who/where that other comment is?

Thanks;

joe b.

John Ardito wrote about long throat length not seeming to matter in the recent TFS. Somewhere, I think on this forum, I read the same comment from another trustworthy source.

Does anyone know who/where that other comment is?

Thanks;

joe b.

Attached Files

Everything matters in the bullet fit equation. One can achieve accuracy with a long throat as long as the bullet is supported and aligned properly before the burning charge starts to move it forward. If you've got that situation under control, half the battle is won. Next, all you need to worry about is alloy, pressure curve and lubrication (assuming your barrel straight and smooth)... which is not exactly a cake walk.

800F

Attached Files

John's match guns use a long, gradual forcing cone of shallow angle, about 1 to 1-1/2 degrees included angle, without a cylindrical ball seat. This is the form used in the CIP for the 7mm and 8mm Mauser, 7.62x54R, etc. In a .30 cal. the major diameter of the forcing cone entrance ahead of the case mouth is typically .311” and the length of the forcing cone is about 0.7” to where the reamer reaches the tops of the lands.

I agree with John that when using the Euro style shallow angle forcing cone (not a “throat") in that the length of the forcing cone does not matter within reason. That has NOT been my experience in typical US design cartridges such as the .308 Winchester which use a cylindrical ball seat which is often larger than the recommended maximum bullet diameter down in the recommended industry manufacturing practices.

For clarification of the nomenclature refer to Mil-Std-1267, Dimensioning of Barrel Chambers for Small Arms Weapons, portions of which were reprinted in FS #76 pgs. 15-16.

73 de KE4SKY In Home Mix We Trust From the Home of Ed's Red in "Almost Heaven" West Virginia

Attached Files

...That has NOT been my experience in typical US design cartridges such as the .308 Winchester which use a cylindrical ball seat which is often larger than the recommended maximum bullet diameter...

Absolutely... and the '06 is a worse offender than the 308; the former typically requiring a .311” boolit with a .15-.16” leading band (to fill the ball seat)... assuming you're looking for 1MOA, that is.

800

Attached Files

Hello, Speaking of long throats & accuracy..When I was working with the 1895 Winchester-Lee .236 Navy straight-pull sporter, that throat was long...a 100gr. Ideal 245498 seated with only G.C. in case mouth still wouldn't reach rifling. Whats worse...the smallest dia. in there was .0005” UNDER groove dia. I had to size 1st. band .001” under G.D. just to be able to chamber. Bullet sized to G.D. & G.C. spring sealed bore ok. Accuracy with the open buckhorn rear & silver blade front was 3/4” at 50yd. 1 1/4” at 100.

Attached Files

I wonder how the Ardito bullets shoot well in a long throat. His bullets are tapered from nose to base and in a long throat would be unsupported until they hit the throat.

Seems to me that they would “wobble” slightly before engaging the throat.

This is when the bullets are “tapered” in the Ardito bump die.

Attached Files

Ardito bump die is cut with same throating reamer used to cut chamber forcing cone. Bullet can't wobble because both tapers match and the bullet is supported by being in contact with the forcing cone. There is no jump.

The long gradual forcing cone angle is ALSO forgiving of free bullet travel because there is less bullet deformation. The lands gradually increase in depth as the taper extends forward. .38 AMU being a good example, having fooled with this form extensively in .357 Magnum single-shot rifles, ordinary .38 Special wadcutters shoot splendidly, despite the long jump in the longer .357 Magnum chamber.

73 de KE4SKY In Home Mix We Trust From the Home of Ed's Red in "Almost Heaven" West Virginia

Attached Files

The Ardito article alluded to having a 6 inch freebore on some of the chambers. That would result in a tapered bullet travelling 6 inches before it hit the tapered throat. Seems to me it could wobble. Ardito's article said there was no effect on accuracy.

Attached Files

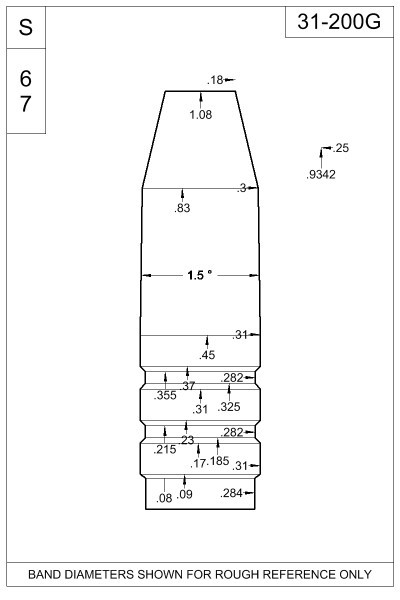

The Ardito article is in the Sep-Oct 2010 TFS, 207-16. Yes, John went from the .3125” to .308” tapered throat forward with a .308” reamer for 6". As I understand it, there was a 1 degree tapered throat .3125” to .308", then the long .308” cylindrical no-lands section for 6". If I understand it. I think the bullet swages down to .308", slides through the .308” dia. section, then sees the lands and starts turning. I think. Someone else, here?, wrote about ~ the same thing. My Competitor .30BR pistol has a throat length such that 314299 GC only seated in the case, is ?1/2” from touching anything. I'm looking for that other cite. Thanks; joe b.

Attached Files

I studied the Ardito throat back in the 90's and as I remember, if it hasn't changed the dimension went like this,

.001 larger than groove depth and .001 below the land heigth in .750. In .004 deep rifling, that equals 27'30” of a deg or .458 deg. It is very similar to the 8mm throat angle of 27' 26” of a deg.

As you can see, the angle can change with the rifling depth. But, I doubt that that was a consideration and considered .004 standard for his work.

The 6” free bore, I doubt that I would ever try.

I've stadardized all my reamers at between 1 deg per side and .750 deg with a .100 - .120 free bore.

Frank

Attached Files

"I've stadardized all my reamers at between 1 deg per side and .750 deg with a .100 - .120 free bore."

Frank,

I think that is about as good as we can get right now, unless some other “breakthrough” comes in the next ten years or so. With a free bore that is 0.001” over groove diameter, I would be thrilled!!!

Ric

Attached Files

The Ardito throat is 1/2 degree per side (1degree total angle). At case mouth .310 to .3125 ( I use .311)tapering at the above angle until clearing the lands. Bullet has the exact same taper and is loaded with just the gas check in the case mouth. On Bolt closing A little resistance is felt as the bullet is firmly seated into its matching tapered throat. Just like a Morse taper chuck fits the Morse taper hole on the tail stock of a lathe. I know John Ardito and got this straight from him many years ago. This will work for fixed ammo if the bullet has parallel sides base to case neck then the taper starts. This allows seating the bullet in the case to a normal seating depth. Lee Wiggins

Attached Files

The Ardito throat is 1/2 degree per side (1degree total angle). At case mouth .310 to .3125 ( I use .311)tapering at the above angle until clearing the lands. Bullet has the exact same taper and is loaded with just the gas check in the case mouth. On Bolt closing A little resistance is felt as the bullet is firmly seated into its matching tapered throat. Just like a Morse taper chuck fits the Morse taper hole on the tail stock of a lathe. I know John Ardito and got this straight from him many years ago. This will work for fixed ammo if the bullet has parallel sides base to case neck then the taper starts. This allows seating the bullet in the case to a normal seating depth. Lee Wiggins

if i'm understanding this correctly, it's exactly what i was planning...except

- shouldn't “if the bullet has parallel sides base to case neck” be case mouth? - i wasn't planning any free bore. other than a few fps it seems to me it's just another variable and variables are EVILLLL. am i missing something?

thanx, bob

Attached Files

rsoper, Yes case mouth. You can have a bullet seated in the case neck to get an OAL of loaded round for magazine feed. That bullet would have a cylinder section in the case neck then the taper at case mouth starts. But the tapered forward part of the bullet needs to be in firm contact with its matching angle throat. There is a down side to this , opening the bolt with a loaded round chambered almost always pulls the bullet spilling powder etc. Ever tried to pull a Morse taper out of its matching hole? Lee Wiggins

Attached Files

The Ardito throat is 1/2 degree per side (1degree total angle).

Thanks for the clarification, Lee.

.

The Ardito article in #207 says “I used a 1 degree tapered reamer,” but he didn't specify whether it was “per side” or “included angle.” Apparently he meant included angle.

John also states “since then I have played with different degree tapers but it did not make much difference.” Hmmm.

I found it interesting that John used an unpiloted chucking reamer for his freebore experiment: 'a standard .308” chucking reamer.' Note that the cutting edges of a chucking reamer are about 45 degrees per side.

John said “I did this in one inch increments up to six inches. It still did not make much difference in accuracy.” Though unfortunately he seemed to be recalling an experiment he did some time ago and did not list any specific loads, velocities, or groups. :( Not that I doubt John's veracity or his proven track record, still, I find the results hard to swallow.

In conclusion, if the leade angle doesn't make much difference, and if the freebore or lack thereof doesn't make much difference, and using a piloted reamer doesn't make much difference, then what does make a difference? Why do some guns shoot better than others if none of those things make much difference?

I also found it interesting that John built a rifle with an action at both ends of the barrel -- why didn't I think of that! :cool:

John concludes by saying “I know I am a nut for doing these things but this is how I learn what works and doesn't work with lead bullets. I love to try things other people haven't done.” Amen. :dude:

It would not be that difficult for me to repeat John's freebore experiment. I have an '06 takeoff barrel that would be a good candidate. If ever I can find time ......

Attached Files

Looking back at match results the “Ardito taper” design AND good fitting concentric “bore riding” designs both do well. I have seen one match where the RCBS 165 Sil won match over one certain Ardito taper design. I recently cut my .308 Sillen barrel throat using a .310 diameter x .75 degree per side cutter and used a matching Accurate mold bullet seated long into throat. The few groups that I shot (as cast and sized) showed an immediate improvement over all my bore riders. So far I am very happy my new Ardito taper design bullet. I may recut my Model 94 Winchester to shoot this .308 bullet also.

Attached Files

Here is the 308 Winchester Uni-Throater (.310 x 3/4) with snug fitting pilot bearing attached. To recut the 30-30 throat I will need slimmer sleeve to stop at shoulder of chamber. Cut a little shallow to allow room for erosion and to clean up throat later using throater.

Attached Files

jeff houck

20

jeff houck

20

Wilderness

14

Wilderness

14

Aaron

13

Aaron

13

Tom Acheson

13

Tom Acheson

13

Spindrift

5

Spindrift

5

alphabrass

5

alphabrass

5