I post this under the ''accuracy''category only because there isn't any ''innacuracy''section.The gun is a Pedersoli High Wall in 38-55.The gun is brand new.At first,I only had bullets of 265gr from my RCBS mould.I beagled it and they come out at .378''.I'd shoot them topping 19 and 20 gr of 4198.At 50,1 out of 3 would keyhole and at 100,out of 5,3 would be out of the target.

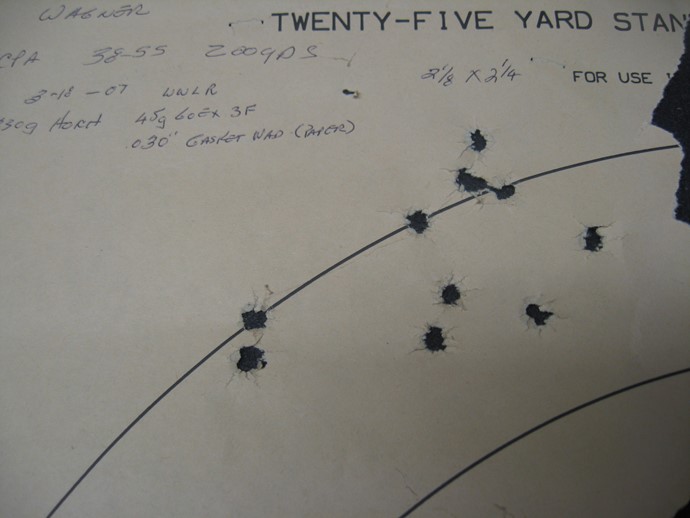

I got me an Accurate mould that casts 330gr .380 bullets(38-270cb with one band added).Either with 17gr 4759(yes,I got a few pounds stashed away)or with 20gr,21 and 22gr 4198 loads,I get the same result.The pattern is, from a cold barrel,the first 2 or 3 rds print good rounded holes and as the barrel warms up,it starts keyholing so that after 8 or 10 rds,the bullets miss the target,and this even at 50 yds.I slugged the bore,.378.So my bullets at .380 are ok.I checked the twist;as advertised,1:12.I don't size and apply 2 coats of LLA.

The puzzling thing is that it does that only when the barrel warms up.I removed the forearm and it bears evenly on the barrel.

Coming home,I dabbed the inner part of the barrel with Ben'd Red;I intend to bring it back onto the bare metal and start over with regular 50/50 Alox/beeswax lube.

Anybody has any idea what is causing this?

.jpg?width=50&crop=0,0,50,50)