Hi guys! I thought I'd just throw out a couple of things for general discussion, valueing your opinions as much as I do... I just was lucky enough to have picked up a Taylors & Co. Uberti Cattleman, chambered in 32-20, 7 1/2 " barrel. MINT, from the collection of a deceased CBA member. Came along with 500 cases and an old Ideal 31357 mould. I've had a hankering to play with a SAA (clone) for years, but never had one present itself until now. So.. First round out with this slick-as-snot sixgun, I found that bullets sized .314, powder coated, then run back through the .314 sizer again would push through the cylinder ball-seat with just a bit of resistance. I loaded up 50 on top of 3.2 gr. of TiteGroup, which Lyman says should make around 850 fps. 25 yard groups were in the vicinity of 2.5".. I was happy, for a "start low and safe.... somewhere!" first outing. Cleaning afterwards, I found a bit of forcing cone and first 1/4 " rifling leading, which somewhat surprised me with the good cylinder fit and powder coat. Anyhow, any experience out there and advice with powders slower than TiteGroup in a 7 1/2" barrel in 32-20? And here's the silly question: Y'all have any tricks for scrubbing lead out of a forcing cone? I mean, run a rod down the barrel, keeping clear of the crown, screw a tight brush on the rod with a few Chore Boy strands on it and pull it back into the cone and twist? It's a tough place to scrub on a revolver! Thanks for your thoughts, and sorry for the rambling post. I have high hopes for this 1873 Varmint handgun!

32-20's & forcing cone lead stupid questions.

- 800 Views

- Last Post 17 June 2022

Attached Files

Duane,

Thanks for the tip, that is a very good price!

Attached Files

Users of the Lead Remover kits will probably find that the screens wear out and need to be replaced. many times you can find a correct diameter bronze pipe filter screen such as below. You will need to make the center hole which is a minor task.

Attached Files

Have you slugged that barrel? Some run .311” or smaller in groove diameter.

I have owned an earlier Uberti SAA in 32-20 that was imported by Navy Arms many years ago. I was told by Val Forgett himself that every one of these in 32-20 that the sold was specially hand tuned in house by the Navy Arms gunsmith including the use of new Wolff springs. This is roughly equivalent to the current Taylor version called “Taylor Tuned” which they make available in all calibers they sell. I know these can be unbelievably slick, even they are “just” Italian copies of the original,

Attached Files

I too load for the .32 WCF. I also have found TightGroup to be the most accurate powder. I am shooting a Colt Bisley 71/2" circa. 1905. I am not getting a particle of lead in forcing cone or bore...only a very light lead smear in some of the cyl. throats which is removed with a few passes of bronze brush. If it were mine, before I did anything drastic, I would try some soft-cast bullet with a soft lube. My alloy is range scrap mixed with soft lead..easily marked with fingernail and a soft beeswax based home brewed lube.

Attached Files

Before doing any carving on the gun metal, you may wish to try smoothing things out with about 50 jacketed bullets at full power. After that I would suggest a Lyman #2 alloy with good bullet lube sized to cylinder mouth size. See what develops.

It seems as though you may be making these decisions based on only one load experience with this revolver. It may handle other loads just fine. Also remember that sometimes we need to press the accelerator down to prevent leading - not ease it up.

I offer this not knowing your experience level so discard this post if I have stated the obvious for you. ![]()

Enjoy that revolver! The 32-20 is a sweet cartridge.

With rifle in hand, I confidently go forth into the darkness.

Attached Files

"Y'all have any tricks for scrubbing lead out of a forcing cone? "

My "trick" is to use a properly lubed bullet............![]()

Concealment is not cover.........

Attached Files

Rather than trying to ream the cylinder throats yourself, and renting a reamer, I highly recommend sending your cylinder to Doug Phillips, aka Doug Guy on Cast Boolits. He does a precision job using a Sunnen hone for an affordable price with fast turnaround. He's done several of my revolvers and also honed sizing dies to match the corrected cylinders.

73 de KE4SKY In Home Mix We Trust From the Home of Ed's Red in "Almost Heaven" West Virginia

Attached Files

I have a Lewis Lead Remover - somewhere. Yes, it worked but it is a royal pain compared to the Choir Boy method.

Get a copper scrubbing pad at the grocery store. Carefully unwrap the pad, don't cut it unless you want copper confetti everywhere. Take an old undersize bore brush and wrap the copper strands on it until it a little larger than the bore.

To do the forcing cone make a larger diameter plug, Put the bore brush into the back of the barrel and attach the cleaning rod down the barrel. Pull and rotate.

This will cut out the lead fast and will not damage the bore. It is cheap and you can make it any size you need.

Several hundred rounds will smooth the barrel and the problem will probably go away.

Steve

Attached Files

Just one more thing. I have heard that on occasion the cylinder ball seats would be too tight, to loose, or a mixture of sizes. I'm wondering if a hand reamer of the correct size can be rented to get the ball seats one and the same size for all chambers? Can this be done at home? Can a reamer be rented by the individual to do this? What company wouod rent hand reamers for this purpose?

Thank you!

GregT

Attached Files

Thanks everybody for the info. on the Lewis Lead remover system. Of course, I've heard of them for years, but never tried one out. Brownells lists a .32 caliber kit, but of course the .32 version is out of stock.. And lotech, will definately give the "double tuff" brushes a whirl. The leading I have is not too severe, so that will probably do the trick.

Attached Files

Mr. Hopper, yes, it's a beautiful handgun. I don' t know if Taylors & Co. gives the Ubertis any special treatment, but if not, hats off to Uberti! The same lady who parted with this revolver also has a S&W 1905 4th change, and a BSA Martini #12 Commonwealth, both chambered in 32-20 (the Martini obviously re-chambered) I have my eyes on both of them! The forcing cone in the Uberti doesn't seem rough. I will run a few hundred rounds through it, with some conventionally lubed bullets and see what develops. After I de-lead of course! Thanks for the suggestion on the Lewis system...

Attached Files

Next best to the Lewis tool is the Brownells "double tuff" bronze brushes; very stiff and will remove leading far better than a regular brush. A .30 caliber will probably work fine for a .32-20. These brushes are so stiff that one even slightly larger might not work.

Attached Files

Hello,

I have a Uberti Model P jr in 32-20 with a 32 H&R mag conversion cylinder. They are nice revolvers.

I use the Lewis Lead Remover tool on all my revolvers. They work very well. Unfortunately, it looks like the .32 caliber version is sold out on Brownell's Website.

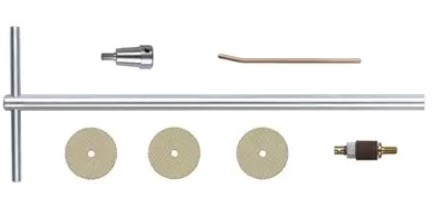

The kit comes with a cone shape head that you put the brass screen on and revolve it in the forcing cone with the t-handle. It also has the rubber tipped tool that you can bump up with the knurled screw to fit your barrel tightly with the brass screen on them and then pull it through the barrel.

I have used steel wool, brass wool and copper chore boy in the past. They all work well, I just find the Lewis tool to work easily and quickly to accomplish the task.

Attached Files

Lewis lead remover if they make one that size. If it were mine, I would put a thin coat of 45-45-10 on the bullets to see if that helped. This may just be a new gun that is not smoothed up yet. Is the forcing cone rough? This can be fixed by a smith that knows what he is doing. I do not recommend an 18 degree forcing cone unless that is what it is now. It sounds like a really nice pistol in a great caliber. I have a S&W Hand Ejector, but have been too busy sighting in rifles this spring to try it out.

Dale M. Lock

Attached Files

Two of the best buys when I started reloading was an impact bullet puller and a Lewis Lead Remover. They are always handy, never know when the need will come.

Recently bought a mix of once-fired and loaded .32-20 brass and pulled the bullets to save the primers. Expand the cases to .32-20 CPA and shoot the factory primers to fireform the cases.

Farm boy from Illinois, living in the magical Pacific Northwest

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

jeff houck

20

jeff houck

20

-

Aaron

17

Aaron

17

-

Wilderness

14

Wilderness

14

-

Tom Acheson

14

Tom Acheson

14

-

John Carlson 13

-

sghart3578 10

-

Spindrift

5

Spindrift

5

-

alphabrass

5

alphabrass

5

-

SkinnerD 5

-

cfp4570

5

cfp4570

5