Well, I'm back to square one.

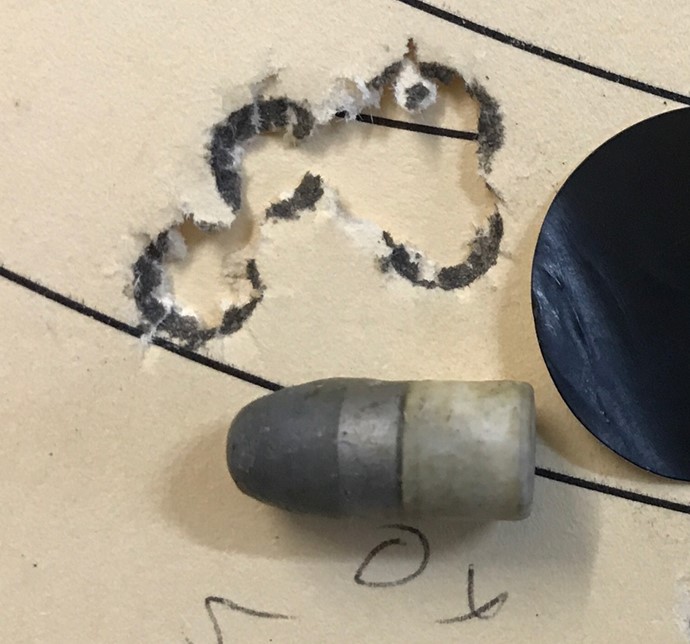

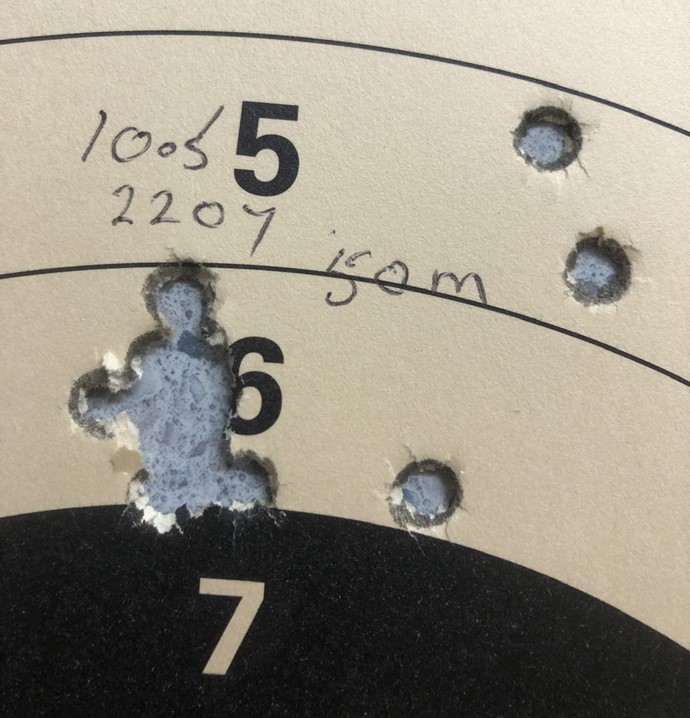

I spent a long time trying to get my .310 Cadet to shoot with smokeless powder and reformed .32-20 brass. Long story short, the neck thickness was insufficient and on firing the brass expanded and the massive blow by of gas caused leading and NIL accuracy. Using correct Bertram brass with neck thickness of 11-12 thou solved the issue and fired cases need no sizing as the heel of a CBE bullet is a snug fit for thumb seating. Instant accuracy.

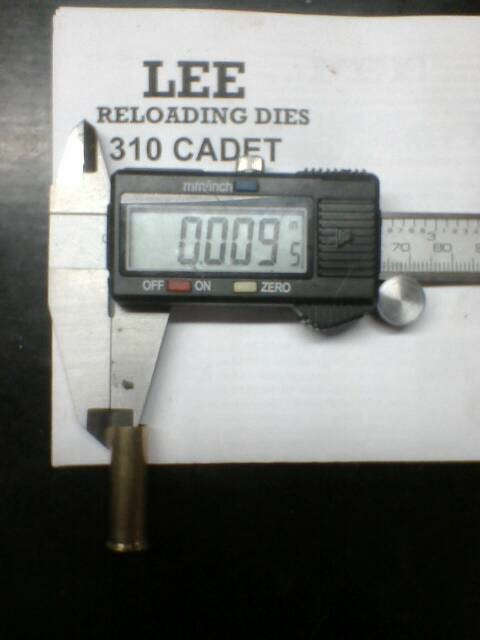

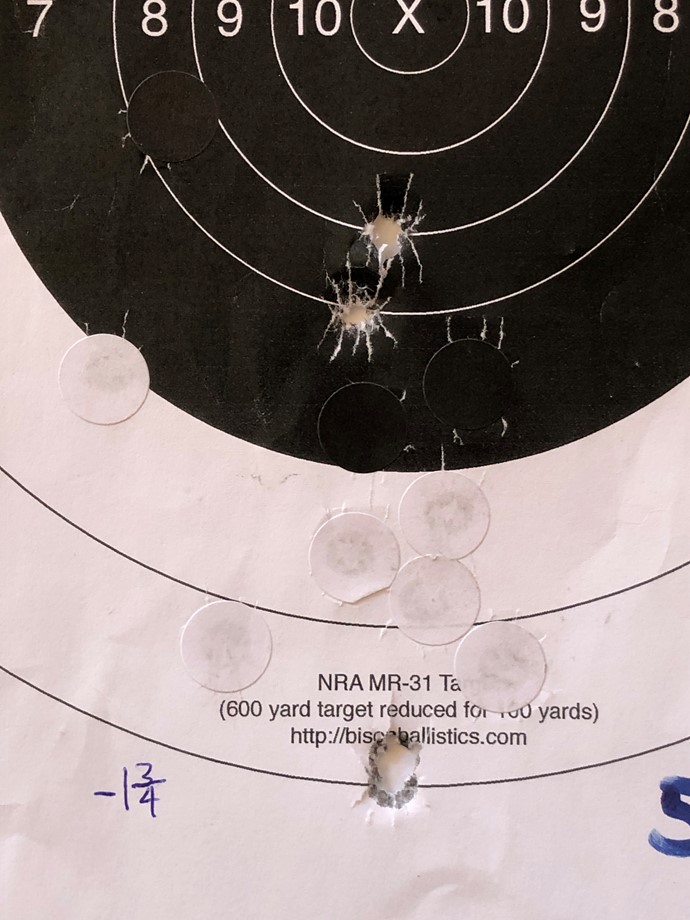

Of course being an idiot I only bought 20 of those cases and recently picked up another 50 to find the walls are thinner. ARGH. 9 thou instead of 11-12 thou. Doesn't sound much but using EXACTLY the same load at 50m the correct dimension old brass shoots 1 inch groups. The new brass is putting bullets sideways and not on A4 paper!

The solution will be to hone out the heel of the mould such that it drops bullets that are a snug thumb seating fit in the fired new brass. The heel will need to be .312 inch. Ideally I believe Cadet moulds should be hollow base as the original swaged bullet are and likewise .22RF with the hollow allowing the base to slug up to seal the bore quickly.

Cheers from New Zealand