When do Bullet Defects Make a Difference?

In the thread “Casting with Lyman Molds” Joe Brennan recently mentioned that he had 40-50 rejects in casting a batch of bullets and that he didn’t know why. Joe says he sorts under magnification so that started me wondering how bad those bullets were and if they would have shot just as well as his “perfect” bullets.

When I started casting I used to get a lot of less than perfect bullets and on some days I still do. Being a depression baby, I don’t like to throw things way and when I got curious and shot the “rejects” against my “perfect bullets” they seemed to shoot just as well. I reported on one such experiment with badly wrinkled bullets in TFS #213 in which the wrinkled bullet’s 5-shot groups averaged .78 MOA and the good bullets averaged .82 MOA. I have tried similar tests several times and haven't found a difference as long as I don't shoot the really gross defects -- parts of a band missing etc.

Joe rejected only about ten percent and throwing away ten percent isn't too painful even for me, so maybe this issue doesn't make much difference to experienced casters. But for beginners that rejection rate may include most of their bullets if they believe that any little wrinkle or slight rounding of sharp edges, or bump on the bottom must be remelted. And that’s what we usually tell them because we don't know ourselves. That may be one of the reasons that beginning casters get discouraged and quit. Early success is important in sticking with a new hobby. If we want more CB shooters we should avoid discouraging them unnecessarily.

What do we know about the importance of defects? I think not much. I hope others, out of curiosity, will compare how their rejects shoot compared to their “perfect” bullets and share their results. We have been at this business for several hundred years and really should know more about the importance of defects by now.

John

How Perfect Should a CB be?

- 15K Views

- Last Post 24 January 2021

Attached Files

What difference do bullet defects make? Not much if the range is short and/or the velocity is low. if you are shooting at longer ranges (100+ yards) and the velocity/RPM is higher bullet defects can make a huge difference in accuracy.

LMG

Concealment is not cover.........

Attached Files

If the bullets are equally “flawed” around the whole bullet, and the diameter is correct, and the base is uniform, the effects could be minimal. Bullet weight does impact longer range trajectory though, and could cause erratic points of impact. I totally disagree with Mike Venturino that flaws are immaterial and that you can shoot anything you get out of the mould. He's primarily speaking about handgun bullets I believe, but I think his performance standards for most bullets are far below my own. In the same issues of whichever magazine he's working for, you can see him get really fussy over his black powder rifle casting, so I know he knows the difference.

My standards are the same for any bullet I make. They need to be of the highest quality I can produce.

Attached Files

My standards are the same for any bullet I make. They need to be of the highest quality I can produce.

We are on the same page, pride of workmanship has a lot to do with what I keep and what goes back in the pot.

Guys that love to chronograph, keep saying the small SD's make smaller groups, yet I have never seen that on the target. Some do, but some don't make smaller groups. Same idea, what you think affects your outcome.

Attached Files

I inspect under a 3X magnifier that has a quarter-sized 6x magnifier in it. With bright light. On a towel I put a bunch of bullets, and push each, point down, along with my finger, so the bullet rolls 360 degrees, as I inspect it. There are NO perfect bullets under 3X magnification. Some are clearly rejects. As the defect size diminishes, the likelihood that I'll reject it goes down. Yet every bullet has some flaw, no matter how tiny. I find it helps me to consider the whole area of the bullet, visible, at the flaw place. A teeny flaw represents a teeny percentage of the area. Like John, I've shot a lot of rejects into small groups. I just finished putting gas checks on a batch of rejects that I'll use as foulers. I find that I need to shoot at least 10 careful shots before going to the record target, and use these foulers to get settled. So, I don't know if defects matter, or how big the defect has to be to matter. Or how to express the size of the defect in what units. Maybe we need a unit of measure of defect. Since I find it easy to cast defective bullets, we could call the unit the joeb. Any bullet with a defect greater than 1 joeb shoots less accurately than those with a lesser defect. As the moving language has given us: “Just saying”

Attached Files

What difference do bullet defects make? Not much if the range is short and/or the velocity is low. if you are shooting at longer ranges (100+ yards) and the velocity/RPM is higher bullet defects can make a huge difference in accuracy.

LMG

LMG

I suspect your first sentence is right. Any way it matches my test results.

Do you have any numbers to go with your statement that defects make more trouble at at longer distances? A certain size wrinkle or a certain radius rounding of the sharp edges will make a bullet hit about ___ inches or feet from the group center in at 600 yards? What rotation speed will start to cause trouble? The bullets in my test reported in TFS #213 were rotating at 126,000 rpm so it must be higher than that.

Does anyone know of any testing that answers the above questions or even indicates that long distance and/or high RPMs magnifies the effects of defects? i would really like to see it since I have heard both stated as fact for a long time. I have tried to find where these facts are established and haven't yet.

John

Attached Files

John, I look at a lot of these statements that should be prefaced by “well, it only makes sense” or “well, everybody knows that that's the way it is.” And, I admit that many times, it only makes sense, or, in fact that IS the way it is. After all, a bumblebee can't fly, and, if God wanted man to fly, He'd have given us wings. Which he did, for Icarus, who, if you recall, came to a rather sticky ending.

I've loaded bullets that I figured would make foulers, and, when fired these defective bullets went right where they were pointed, I've loaded beautiful stuff, that just didn't shoot well; in a shooting session a few days before, they shot well. Same powder, identical in every respect that I could check. I still don't know why this stuff did/didn't shoot well.

And, as I sit here writing this, I still can't pinpoint the reasons for good/bad. And, if Joe, who has a tighter statistical hold on this subject than anyone else I've ever seen, well, if Joe can't quantify it, I'm not too sure it can be done. At least in Dr. Mann's lifetime and probably mine also.

But, I still don't intend to quit trying. It's too much fun!

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

Jacketed rifle bullets are more accurate in my 308 NATO chambered Remington, even with it's loose .311 diameter free bore and long jump to rifling. Is it because the jacketed bullets are more perfect and deform less when fired?

Attached Files

Opinion: nope because they are about 15,000% harder than lead.

Attached Files

Joe, I like the idea of using joeb as the unit to indicate the degree of a defect. Figuring out how to measure joebs would be tough, maybe impossible because there are different types of defects and I can't imagine how to quantify a wrinkle.

I discussed that problem in my article and proposed using photos to show levels of defects. The defects in my photos are wrinkles (we would also need at least a rounded edges and base bumps as two other categories.) My tested “reject” bullets had pretty hairy wrinkles yet shot slightly better than the good bullets so they would have to be less than 1 joeb -- maybe we could call them .8 joeb grade.

Even the results of that one test could be used to offer useful advice to a new shooter having trouble eliminating wrinkles. I think showing my wrinkled bullet pictures and advising him that if the wrinkles don't look worse than these pictures they will shoot OK might be useful information.

Or we could give advice by description. Rounded edges -- gas checked bullets will probably shoot OK unless the bands aren't full diameter (good if smoothed by the sizing die) and unsized gas checks don't fall off. I'm not sure that this statement is true but we could test and find out.

These proposed ideas may sound strange but I think some such approach would be better than telling a beginning CB shooter that the bullets should look perfect which is what happens now. That statement probably isn't true but it could discouraging to a new shooters learning to cast.

John

Attached Files

On the fence on this one. Not so much the testing of the good, the bad and the ugly at long distances. But more of an inconsistency at the bench when we experience the “this load shot good a few days ago but today it stinks” conclusion. We need to look beyond the so called inconsistency of the quality of the bullets and look in the mirror and convince ourselves that our bench technique is repeatable day after day. Failing that bullet quality takes a way down the list second seat.

Tom

Attached Files

Life is too short to compete with imperfect bullets. The easiest variable to eliminate, particularly in the PB class. If the base is good, the bands square, and no wrinkles, they go into my score box sorted into 1 gr weights. I'd rather spend my time doping wind and mirage than wondering if that “marginal” bullet cost me that 10 or X. C'mon, a glance will tell the tale, if it is not good in your heart of hearts toss it back into the reject can.

Attached Files

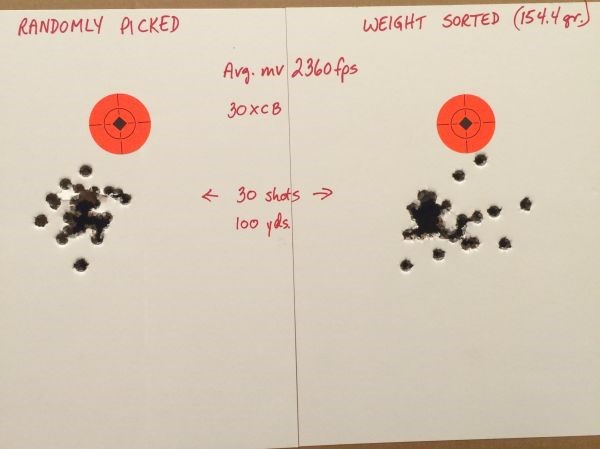

Well from the jacketed world, try a bag of 147 grain M80 pulled from 7.62x51 NATO cartridges. A few blemishes but not too bad, weights however vary by +/- 2 grains. Load them randomly and they have about 4 MOA at 100 yards from a M1903 A3 with iron sights, shot prone with a sling. Sort them into weight groups and you can maybe get to 2 MOA. The control would be to not know what I was shooting (If I know their better maybe I shoot better?). The same rifle in the same conditions shoots well sorted cast, fitted to the throat about 2 MOA at 100. A factory modern rifle, with a scope and bench rested might make everything tighten up but I believe the trends would continue.

I am with Ric, if you make them, make them as good as you can and you will have better accuracy.

Dave

Attached Files

Well said Tom. Folks go to great lengths to place the blame on small defects or this powder, that primer etc. All to get around the obvious, they have poor technique! No amount of fastidiousness in bullet prep. will overcome personal inabilities. That being a big part of why I shoot plates, gongs, and beer cans instead of benchrest targets. lol Gp

Attached Files

Early in my association with the CBA I read some posts on this subject so decided to try my own test.

After a few of my first casting sessions I weighed several hundred bullets. I was able to assemble two sixty bullet test batches. Each batch had 30 bullets in the middle of the weight range, 15 of the heaviest bullets, and 15 of the lightest bullets, slightly less than 4 gn spread from heaviest to lightest. I shot five shot groups at 100 yards alternating between groups with the “perfect” bullets and groups with either two heavy/three light or three heavy/two light. In the end the “perfect” bullets averaged 1/4” tighter groups (1.24” vs 1.52").

Coincidentally, my first win was in an informal match shooting groups at 300 yards. The margin of victory was 1/4".

Of course as always there's “the rest of the story".

As anyone should be able to tell you (though many can't) for the results of any experiment to be valid they have to be repeatable. Through the summer the second batch of test bullets sat in a box while I prepared for matches and learned more about casting techniques, shooting techniques, etc etc etc. Finally on a reasonably nice December day I headed for the range with the second batch of bullets. I have no idea why but this time I could barely muster groups around three inches and the most charitable way I can put it is that I was unable to validate my earlier experiment.

In the meantime I have learned to cast more uniform bullets, use more uniform pressure when sizing, work with seating depth, etc etc etc. Even so, as the winter gets longer and colder, when some of those “honeydo's” come along, I may find it useful to have a large batch of bullets that really need to be sorted..>

John Carlson. CBA Director of Military Competition.

Attached Files

I'm in the camp with Tom, gpidaho and John C. The human factor is rarely added to the mix and in my opinion should always be at the top of the list of why thing go right and then go wrong the next time out when everything else is the same. I have since quit worrying about bullets, powder charges, loading procedure etc, etc, etc,---. Any more I concentrate and continually struggle with consistant bench technique and the fundamentals of marksmanship. Over time, I have learned how my rifles shoot with the loads I use. That is the constant. My application of technique and the fundamentals are not, on any given day. And as far as casting bullets go. I figure that as long as I am going to spend several hours and maybe days making bullets, they might just as well be as good as I can cast them and then let it go at that. Because I have also learned that the one great variable in all of this is me.

Attached Files

Now I remember. The memory is the second thing to go. 3.5 damaged bullets - See attached file below.

Attached Files

What difference do bullet defects make? Not much if the range is short and/or the velocity is low. if you are shooting at longer ranges (100+ yards) and the velocity/RPM is higher bullet defects can make a huge difference in accuracy.

LMG

LMG

I suspect your first sentence is right. Any way it matches my test results.

Do you have any numbers to go with your statement that defects make more trouble at at longer distances? A certain size wrinkle or a certain radius rounding of the sharp edges will make a bullet hit about ___ inches or feet from the group center in at 600 yards?

What rotation speed will start to cause trouble? The bullets in my test reported in TFS #213 were rotating at 126,000 rpm so it must be higher than that.

John

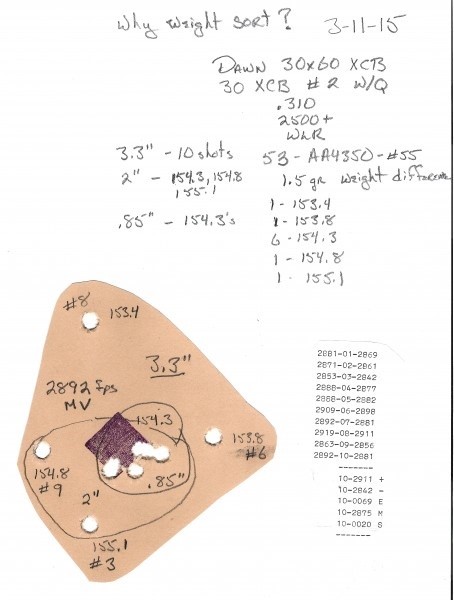

There is indeed and RPM Threshold where accuracy goes south due to adverse affect increased RPM has on the imbalances (what defects in the bullet cause). With the ternary alloys we commonly use and the usual fast to medium burning powders the RPM Threshold will generally fall between 120,000 and 140,000 RPM. The things that push the RPM Threshold up are better bullet designs that fit the throat, better balance of antimony and tin in the alloy, less defects in the bullets (consistent bullet weight and shape), consistent loading techniques, a proper lube, a slower burning powder to lengthen the time/pressure curve and numerous others. If you do everything right you can push the RPM Threshold above 140,000 but at some point (the faster the barrel twist the sooner) you will cross the RPM threshold and accuracy will go south very quickly, especially at longer ranges as non-linear group dispersion occurs.

Does anyone know of any testing that answers the above questions or even indicates that long distance and/or high RPMs magnifies the effects of defects? i would really like to see it since I have heard both stated as fact for a long time. I have tried to find where these facts are established and haven't yet.

There are several threads on the CBF and the NOE forum answering that very question(s). Considerable work has been done pushing cast bullets of .30 caliber to higher velocities by pushing the RPM Threshold above 140,000 RPM. This has been done with 10 and 12” twist barrels using the .308W and 30 XCB Cartridges. The .308W and 30 XCB cartridges with 14” twist barrels has also been used very successfully pushing the Lyman 311466 and the NOE 30 XCB bullet to 2600 fps while maintain 1 - 2 moa accuracy to 300 yards with 10 shot groups.

A couple of us have pushed the ternary alloyed bullets to 3000 - 3100 fps with some success. However with my 30x60 XCB cartridge in a 16” twist barrel I can consistently hold 1 - 2 moa through 300 yards. I recently shot a 20 shot group at 300 yards that stayed very close to 2 moa with a velocity of 2900 fps. The first five shots were in 1 moa and the first ten shots were in 1 1/2 moa. A 20 shot test string is admittedly difficult at 100 yards let along 300 yards. I am currently still experimenting to improve accuracy.

Given the fact that most “defects” in different bullets from the same casting will not be identical in shape, weight or location on the bullet the centrifugal force will act on them differently. Therefore it is impossible to say they will hit “X” distance at 600 yards from the center of the group. However, there are formulas in several ballistics books that you can compute the effect a consistent defect in your bullets would have.

However, I don't find I can cast consistent defects so I don't bother with such mental strain. I cull the defects as best I can by visual inspection (pretty much the same as joeb does with a magnifier) and by weight sorting.

LMG

Concealment is not cover.........

Attached Files

I fall into the group that says, “why shoot bullets that don't look or weight well, in matches"

I shoot PB bullets at 200 yards and while I can repeat good results, I can't repeat them every time. Wind drift is the highest at the velocity range for PB (14 - 1500 fps) and I chock it up to that and me missing a condition.

I keep some imperfect bullets to use as foulers and they will almost always shoot into the same group, after the barrel is fouled BUT, I can't bring myself to shoot them into a record, match target.

It maybe interesting that they can do that but, why do we care?

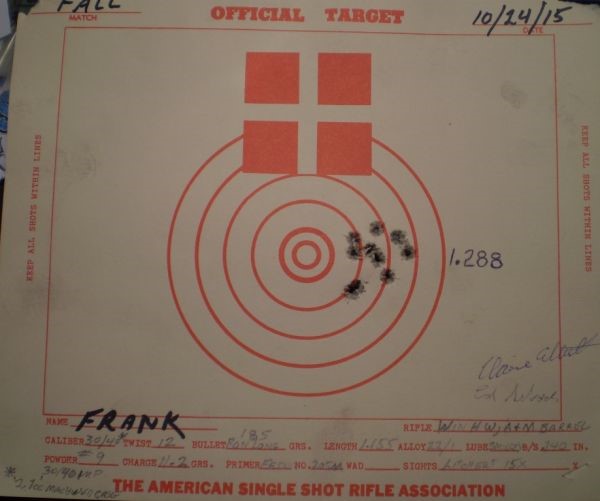

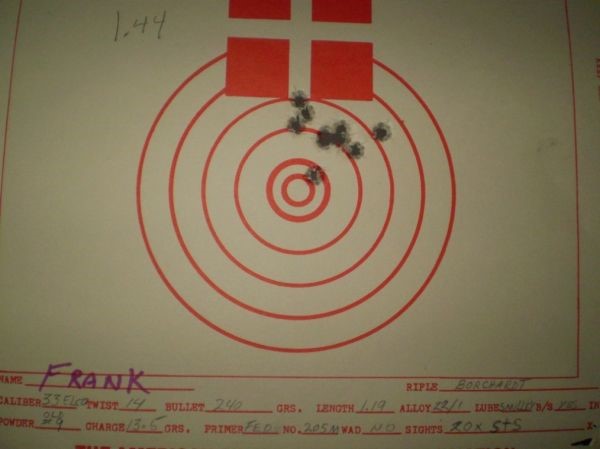

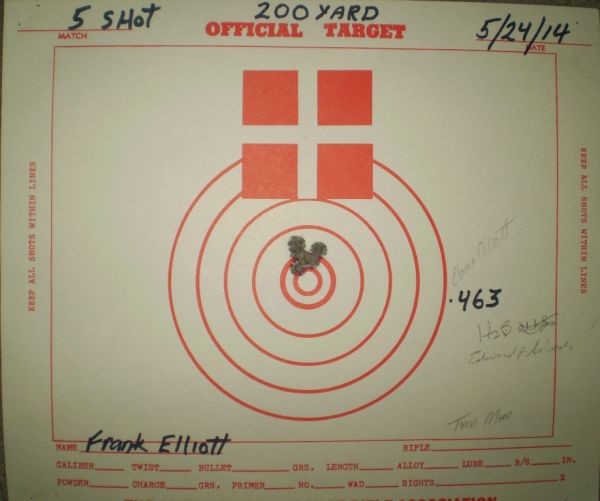

Frank

Attached Files

"1 - 2 moa accuracy to 300 yards with 10 shot groups."

I don't think that the above is really considered accuracy if measured against CBA, ISSA or ASSRA match shooting.

You gotta do better than that to have any relevance.

Mel Harris (Roseburg, OR) gets groups of 1/3 to 1/6 that at 158K rpm, with a 212 gr bullet.

Frank

Attached Files

Wineman and Carison,Thanks for contributing results of actual shooting tests. We need more such data. It is interesting that the max wt. variation was about 4 grains for both bunches of bullets yet weighing reduced group size by a spectacular 50% in one case and only 16% in the other?

Joe,Thanks for all the data. I tried to struggle through it and if I understood at least one part of it indicated that filing .2 is not likely to hurt accuracy enough to pick up in the number of groups a rational person would be willing to shoot.

Tom,I agree with you and the others that the most important action is at the bench but that doesn't mean we shouldn't try to understand what counts and what is just a waste of time in making the ammo. The whole picture is what makes it interesting.

John

Attached Files

NO! He said “bullet RPM". No,now I said “bullet RPM"

There is another reason that craftmanship is its own reward. When you show newer casters your work, and it inspires them to try just a little bit harder for better quality. They seem to appreciate their progress just a little more when they make their breakthroughs.

Attached Files

I fall into the group that says, “why shoot bullets that don't look or weight well, in matches"

I shoot PB bullets at 200 yards and while I can repeat good results, I can't repeat them every time. Wind drift is the highest at the velocity range for PB (14 - 1500 fps) and I chock it up to that and me missing a condition.

I keep some imperfect bullets to use as foulers and they will almost always shoot into the same group, after the barrel is fouled BUT, I can't bring myself to shoot them into a record, match target.

It maybe interesting that they can do that but, why do we care?

FrankFrank, I care first because I am curious and second because I think we drive off potential CB shooters by telling them they should examine their bullets under magnification and sort them to .1 grain lots. Us fussy CB shooters like to do that sort of thing but a new shooter trying to get below a 2” group average shouldn't bother his head with such minutia because it won't help him and other things are so much more important. If later he wants to spend his time sorting bullets and taking pride in his finely sorted bullets fine. In order to ask CBA members NOT to load extra unless work on beginners we need the facts.

I know that most competitors can't bear to shoot record shots with bullets they haven't sorted by weight. Great, it's a hobby after all and we should do it the way we like. Personally I am afflicted with an engineering (or maybe depression baby) personality that makes it hard for me to waste time and effort doing things that I know won't improve my scores just because I can or ought to. I weigh sorted bullets for many years until I ran tests and saw that it was a waste of time. I haven't weigh sorted bullets for twenty years. I believe my time is better spent as Tom suggests. Different strokes etc. etc.

John

Attached Files

John, if they really want to learn CB benchrest shooting, it is 5 ten shot groups every week. After a few months of casting and shooting they will be good to go. They just have to learn two skills; making bullets and shooting them. If they just want to plink, they can start shooting with the first bullet they cast! Ric

Attached Files

Greetings, joeb33050, thank you for the data and in a presentation and format easily understood. I, for one, find the data very interesting.

TK

Attached Files

Once again, Joe has nailed it with systematic experimentation, a lucid explanation of what happened, and a numbered analysis to show how much. Quantitative-qualitative. Thanks. Interesting substance for those of us trying to improve our CB groups, and scores. I suggest that, while technique may very well enter into group sizes, technique won't explain 3” to 4” groups, when the same shooter/rifle can put jb's into

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

My last sentence was cut short. I wanted to say that most of us can probably put jb's into <3/4 minutes. Dunno what happened. Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

i'll have some of what mel is having ...

ken

Attached Files

Frank 1 - 2 moa at 300 yards holds “relevance” in hunting and it also holds the X and 10 ring on the 300/600 NRA NMC target which is “match shooting".

I have researched all the CBA records and find no records of anyone shooting 1/3 to 1/16 that at 300 yards at HV with 10 shot groups. Actually I find no matches of any sort held by CBA at 300 yards. We have been through this before Frank so I'll take a moment and refresh your memory; the goal was to achieve 2800 - 2900+ fps with a naked ternary cast bullets holding 2 moa or under with 10 shot groups while maintaining linear group expansion to 300 yards. That is not the goal of CBA, ISSA or ASSRA so I see no relevance in the comparison. That is the goal of what I and several others are doing. Is it stated somewhere that all cast bullet shooting discussed here must adhere to CBA, ISSA or ASSRA match records"? However, let us consider the NRA does shoot matches at 300 yards with 20 shot strings. So far I have shot a “clean” (200 points with 20 tens) on the 300/600 yard NMC target with the 30 CXB bullet at 2900 fps . As I mentioned in my previous post I am now working on improving accuracy to shoot master level or better scores on the 300 yard “F Class” target. F Class is also a very popular NRA match. That's where the “relevance” is as that's the match accuracy consideration I am using for high velocity cast loads.

So let me ask Frank, what moa have you shot with 10 shots, let alone the 20 shot strings required for the relevant NRA NMC and F Class matches, at 300 yards at 2800 - 2900 fps? Have you “cleaned” the 300/600 with 20 shots? Has Mr. Harris of Roseburg with that 158K load? Doesn't the “relevance” come only when apples are compared to apples and not oranges?

BTW; if you read the NOE forum on my HV testing in 10 and 12” twists you will see I also demonstrated how you can push the RPM Threshold up. I shot numerous 5 shot groups into sub moa over 140,000 RPM; 145 - 171,000 RPM actually. However, none of those were at 2800 - 2900+ fps. Excellent accuracy is quite possible at over 140,000, especially at 100 yards, I consistently demonstrate that. The same can also be done at 200 yards but it is much more difficult, especially if you consider the 20 shot strings required for the NMC and F Class matches. So Frank, please,when you can shoot 10 shots, let alone 20 shots, consistently into 1 - 3” at 300 yards (that's what your claimed “of 1/3 - 1/6 that” really is) at above 140,000 RPM would you please come back and show us how it's done. I for one would really be interested to know.

LMG

Concealment is not cover.........

Attached Files

i'll have some of what mel is having ...

ken Mel is exceptional. He is recovering from colon cancer and is a little off his game, right now. He shot 199's, in his last two matches. He was second in Nov. and won the match in Dec. The Dec. match was at Roseburg and he also put the match on. Frank

Attached Files

"I care first because I am curious and second because I think we drive off potential CB shooters by telling them they should examine their bullets under magnification and sort them to .1 grain lots. Us fussy CB shooters like to do that sort of thing but a new shooter trying to get below a 2” group average shouldn't bother his head with such minutia because it won't help him and other things are so much more important. If later he wants to spend his time sorting bullets and taking pride in his finely sorted bullets fine. In order to ask CBA members NOT to load extra unless work on beginners we need the facts."

John, please don't get me wrong, I agree 100% with what you said (quote). Yes I do get “fussy” and into the “minutia” as it is necessary. It is necessary when pushing cast bullets to high RPM and for the utmost in accuracy. However for most cast bullet shooters who shoot at close range (100 yards and under) the requirement to weight sort and anally inspect the bullets is necessary at all.

For most of my casual handgun loads I have shot many a wrinkled bullet down range. They shoot just fine, Usually the only thing I cull such a handgun bullet out is when the base is not completely filled. On rifle bullets small wrinkles don't bother me at all and I shoot a lot of them. Actually I shoot most of the “culls” from my match bullet sorting in other rifles at more sedate velocities at targets such as gongs, racks and dirt clods.

Even in some match shooting such as cowboy action (SASS) the steel targets are large and at close range (10 yds and under for pistol and seldom over 25 yards for rifle) so wrinkled bullets do just as well. Even with my Trapdoor 45-70s which I use for longer range shooting I don't weigh the bullets. I just give them a cursory visual inspection when casting. Those with wrinkles, not filled out or other defect are usually put back into the pot.

You are right though, a lot of cast bullet shooters are turned off on this forum because some members here want every one to adhere to strictly their own style of match shooting and accuracy standards. That certainly turns a lot of probable members off.

LMG

Concealment is not cover.........

Attached Files

heh, yep i used to converse a bit about the exploits of your area successful cast shooters .. with my friend and national record holder lloyd de vore . one of the few shooting books i hang onto is a copy of _single shot actions ...their design ... _ autographed by both de haas and publisher lloyd de vore .

haven't heard from loyd for a few years ... hoping he is still around .

ken

-

Attached Files

OK Larry, I encourged you to shoot matches with the CBA, back when you still lived in WA but, you wouldn't do that. You have a group of High Power shooters where you live now. Have you shot any matches with them, if so, where are the published match results from that? It's nice that you can shoot 3000 fps w/o leading but, please don't tell us that it's even close to match accuracy. BTW, velocity has never won a match that I know of! You are now talking to match shooters, we have our results published in in national publications for all to see and to be varified. We don't put targets up at some un-witnessed and un-varified distance and shoot at them and score them ourselfs. I could put targets up at 50 yards and shoot 50 shots into them and tell everyone it was shot at 300 yard target but, I choose to compete in matches. Although I don't hold any national records, I do hold all but, one of our club records, all shot at 200 yards. These 3 targets that I will post are between .097 and .030 off the ASSRA national, match records, shot in matches and published in the American Single Shot Journal. I will also post the target you said was shot at 300 yards and I assume it's the single best CB target you've ever shot at that range but, I really want to see your published match results, I know the Hi Pwr boys will let you shoot CB with them. Personally, I don't care about velocity or RPM, what I do care about is that you tell people that as RPM goes up, accuracy will go down, and that it has crossed some “threshhold", the word threshold means that you've crossed something and it's different on the other side. If someone proves you wrong, you just say that they have pushed “your” threshold up, not that your wrong about it. CBA results prove that match (not casual, unvarified) accuracy is good to around 160,000+ RPM. I believe you need to rethink what you tell everyone. Mel Harris: Single, 10 shot, 200 yard, group records: UnR, .886 UnP, 1.009 10 shot Agg. group records: UrR, 1.0225 UrP, 1.267 100 & 200 yard, (combined) MOA, 10 shot group record: UrP, .645 MOA Those are just a few of his more than 12 different CBA records. Frank

Attached Files

How Perfect Should a CB be? That would probably depend on how hard an alloy is. Softer 12 bhn bullets could probably get away with more defects than harder alloys. Bullet fit is way more important.

Now what is the best design? A good fitting bore rider that works well in a good tight chamber designed for jacketed. Or a taper bumped bullet that is subject to throat erosion over a period of time and not fitting well later on. What about the original LBT designs that require a longer leade no larger in diameter than .0005-.001 over groove diameter.

Attached Files

Frank, give us a break. I am talking about accuracy at HV, not just accuracy. I have told you that time and again. You invite me to just shoot for accuracy which is not what my intent is. I have invited you, since you are critical of what I am doing, to attempt what I am doing; accuracy at HV. You won't, yet you still post targets that are just for accuracy, you won't attempt what I am doing yet you still criticize what I am doing. Maybe you should “walk the walk” before you criticize.

How many groups did you shoot that day? How many groups did you shoot before you figured out what it takes at 200 yards? You show us the best you have done. I showed you the first and only target I've done at 300 yards with a 20 shot string and stated load development was still in order.

So let's see, on the target of mine you posted it is the 1st target I shot for score at 300 yards and if you'll notice there are 20 shots there, not 5 shots at 200....not 10 10 shots at 200.....but 20 shots at 300 yards. That target is the 300/600 NRA target for the NMC. It is the “standard” for accuracy and competition matches which I shoot. I've since switched to the 300 yard F Class target on which the 10 ring is the same size as the X ring on the NMC target. The X ring is half that size. That is the measure of “accuracy” I'll be using at 300 yards.

What measure of accuracy are you using at 300 yards with HV cast bullet loads? Oh, I forgot, you're shooting cast bullets at 1400 fps at 200 yards. Why don't you double that velocity and add another 100 yards to the range. Then come show me what you can do. You also continually post records. How many times are those record size groups shot? Did the record holders fire that group as the first group they fired with that load at that range? What was the worst group the record holder ever fired with that load? What was the average? Has the record holder ever fired a cast bullet load at 2900 fps at 300 yards? Yes I do still shoot local unregistered prone matches. We shoot once a month. Everyone else (usually 8 - 12 shooters) shoots F Class. I am the only one shooting NRA NMC Match Rifle. All shooting is done prone at 300 yards. The others use the 300 yard F Class target. Since I shoot prone with only a sling support and with iron (match) sights instead of a 20 - 35X scope I use the NRA 300/600 reduced target. We shot yesterday as a matter of fact. I switched from a 69 gr MK to the Hornady 75 gr Match bullet so my zero wasn't any good. Took my 2 sighters and 6 more shots to center up (targets are not pulled and marked so I had to spot the shots which is very hard to see .22 cal holes at 300 yards even with a 25X spotting scope). Thus my fist string was a 189-6X. The next, now having a good zero was 197- 8X and the third string was a 198 - 8X. The last two strings were my usual High Master level scores. If that doesn't suit your idea of accuracy or ability to shoot it's just too bad Frank. LMG

Concealment is not cover.........

Attached Files

Larry, i hate to say this but, how do we know that target was even posted at 300 yards? How do we know that Mel's targets and my targets are posted at 200 yards?

We have all seen people post targets over on the boolit site :)

It's much easier to shoot in registered matches, you only have to pull the trigger, others do the rest.

The people on this site, have no doubt as to a person or a rifles accuracy when they shoot in matches.

"How many groups did you shoot that day? How many groups did you shoot before you figured out what it takes at 200 yards? You show us the best you have done. I showed you the first I've done."

I've shot singles shots, since 1985 and I'm still learning and improving.

As far as the first you've done, you've post a huge amount of targets that would place you at the bottom of CB matches, so to date, I'd say that although not match quality, it's is your best.

Want everyone to believe you about what you exspouse about shooting, get with those Hi Pwr guy and prove it, there will be no doubt if we see it published!

That's all I ask and it should be easy for you to do.

As for me shooting at any other velocity than I choose, that is for me to decide, not you. If you would like a challenge, try shooting competive single shot groups at 1400 fps. Most bolt actions have a lock time advantage so, it should be easier for you to do with a bolt gun.

Again, it's nice that you can shoot at HV w/o leading :)

Frank

Attached Files

"Yes I do still shoot local unregistered prone matches. We shoot once a month. Everyone else (usually 8 - 12 shooters) shoots F Class. I am the only one shooting NRA NMC Match Rifle. All shooting is done prone at 300 yards. The others use the 300 yard F Class target. Since I shoot prone with only a sling support and with iron (match) sights instead of a 20 - 35X scope I use the NRA 300/600 reduced target. We shot yesterday as a matter of fact. I switched from a 69 gr MK to the Hornady 75 gr Match bullet so my zero wasn't any good. Took my 2 sighters and 6 more shots to center up (targets are not pulled and marked so I had to spot the shots which is very hard to see .22 cal holes at 300 yards even with a 25X spotting scope). Thus my fist string was a 189-6X. The next, now having a good zero was 197- 8X and the third string was a 198 - 8X. The last two strings were my usual High Master level scores. If that doesn't suit your idea of accuracy or ability to shoot it's just too bad Frank. LMG” It's a High Power match, where might we find the published results? Can you give us a link to it? Why not shoot CB's in that match? Frank PS I forgot to post my 600 yard target, it wasn't shot in a match though

Attached Files

I do not, nor will I ever, understand why it has to be this way. I built the rifle Larry used to shoot the targets he has posted. I built it for the pleasure of seeing what could be done, and the objectives were clearly stated as being tailored towards HV shooting where very few cast bullet shooters have successfully achieved any level of predictable accuracy. I had hoped to get help from people who have made it their business to achieve accuracy in any circumstance and any set of rules, but the entire project was met with resistance from the very beginning from those who only accept results if they fit they're style of shooting.

At no time were targets posted that were shot with jacketed bullets or at lower velocity, or at closer range just to prove the point that people can lie about their targets and there is no way to prove otherwise. We would not stoop that low. LMG's results were personally witnessed and reproduced on his range with his rifle by another shooter.

It was extremely difficult and took significant expense by myself and others in order to make what progress we have achieved a reality, but there are those who would give their last dollar to make sure that our efforts are buried and forgotten forever because they care more about an adolescent vendetta than they do about the science that is being pulled up by it's bootstraps.

I don't understand this. I will NEVER understand this. This sport used to be pure, and now it's corrupted by those who reduce the sport to a convenient size and shape that fits perfectly in a box of their own design, at which point the lid is slammed shut and anything that is hanging over the edge gets cut off and thrown in the garbage. Why would I want to be a part of that?

Attached Files

Frank, Your classless attempt to smear Larry Gibson is duly noted. I have shot with Larry and to me and many others there are few shooters out there who are held in a higher esteem than Larry, especially when it comes to personal integrity.

Let me assure you that targets were indeed posted at the correct distances.

Attached Files

Each of the various marksmanship disciplines has it's own set of standards. Comparing the results one achieves with a Rem 700 sporting a match grade barrel with those someone else achieves with a Garand is meaningless. No one discipline is superior to any other, they're just different, and that's supposed to be OK. BTW is one checks the Military Match Records you will find that the CBA does indeed sponsor 300 yard matches.

John Carlson. CBA Director of Military Competition.

Attached Files

Calm down guys, your on a competitive web site, all I'm asking that you post results, shot in matches. There are CBA matches, held, all over the USA. Is that really to much to ask? I shoot in matches, at least 15 times a year. The ISSA & ASSRA matches that I shoot in are restricted to non-bolt action rifles but, I also shoot in the Roseburg, CBA matches in the PB class. My results there, aren't posted on this site because, I'm not CBA member.

Match shooting is fun and can certainly hone your skills, especially if you ask questions of the fellow competitors.

About two years ago, on the boolit site Larry, questioned the CBA, equipmemt lists, indicating that the info, from match results, that I posted from there is suspect because, it didn't adhere to his “threshold” so, I'm not sure what his motive is, posting here. Trust goes both ways.

I'm only interested in accuracy, if it's not there, it just isn't of interest. HV with low BC bullets is counter productive when it comes to accuracy, also. For accuracy, we fight wind drift more than any other thing and low BC bullets have more wind drift.

Frank

Attached Files

There ARE NO MATCHES for our type of shooting. We are doing something NEW. For us, targets posted is as good as it gets because this is not a mainstream discipline. You sit on a high horse because you chose the path more followed and thumb your nose at my hard work and that of anyone else? Brilliant. Accuracy is all any of us really care about but for a man who is disciplined in one in one form of shooting to call BS on the hard work of a man shooting in another because he is unable to demonstrate the same level of accuracy is just plain absurd and carries an impressive deficit of class or courtesy. That's not competitive spirit, that's acting like a thug with a target rifle. Bad form! You are comparing 200 yard groups to three hundred yard groups and wagging your head. You are comparing groups shot with lead at less than 2000FPS to groups shot with similar bullets at 1000FPS faster. What we are doing is inherently more difficult and more challenging in every way and cannot be compared flippantly to normal cast bullet shooting. We do not have the benefit of hundreds of years of real competitors shoulders to stand on. We've only been at this for about 2 years and who knows how accuracy will improve once we learn how to refine the process over the next hundred years or so.

Attached Files

John Carlson

I checked into those also. Problem is I'm not shooting a military rifle. Nor am I shooting a single shot. I also am not shooting just for accuracy but for high velocity and accuracy. I see a lot of familiar names on the scores posted. I used to belong to Paul Bunyon and shot in many of Mitch's military matches (not cast bullet matches) there.

Let's take a look at just accuracy anyway. Noting the match wining 20 shot agg was 3.086” at 300 yards in the modified/scope class I knew I still had a bit of work to do as I mentioned. Noting the 20 shot for score (agg of 2 ten shot strings) was 200 - 12X score I may still have been “in the running” so to speak. The match results do not mention the target used at 300 yards though and I'm unable to find it in the rules.

What I didn't claim with the target Frank posted here in the original thread on the CBF it was posted in was that it was the bestest and greatest. I simply was posting the results of continued testing.

Now the difference between those CBA Military rifle match results and my results are this: I was also pushing the cast bullet at 2900 fps. The competitors in that match were pushing their bullets at about (+/-) 1000 fps less. That is a difference, a very big difference.

Do you know what target was used at 300 yards in those matches?

LMG

Concealment is not cover.........

Attached Files

Can't someone put a stop to this meaningless bickering? The very same reason I never go to that “other” forum.Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

Frank

Do we belong to two different Cast Bullet Associations? Oops, I see you're not a member of this CBA. I ask because apparently you have the mistaken impression this is just a “competitive web site". Well if you were a member perhaps you would have read the CBA Bylaws, particularly this;

The Cast Bullet Association Inc. Nature and Purpose

The Cast Bullet Association is an organization of shooters who enjoy shooting cast lead bullets in rifles and handguns for competition, hunting, or informal target shooting. The Association's central purpose is to help shooters enjoy cast bullet shooting by:

Stimulating and encouraging experiments in casting and handloading cast bullets that will improve the design, accuracy and effectiveness of the ammunition and increase the satisfaction and enjoyment of shooters.

So, in line with the Bylaws of this Association of which I am a member I shall perceiver to endeavor at casting bullets that improve upon the design, accuracy and effectiveness AT HIGH VELOCITY and there by increase my satisfaction and enjoyment in doing so. I shall also post the results here and in other forums regardless of your inane objections.

And BTW; regarding your “blowing smoke” 600 yard target......there is an old saying that “1st liar doesn't stand a chance"....that target of mine was actually shot at 1000 yards.....I only said 300 yards because I didn't want to embarrass you.........:wnk:

LMG

Concealment is not cover.........

Attached Files

Bill, there is a solution to the “bickering". Just take what the man says at face value. If you chose not to believe him do so, but don't attack him at least that is the most polite way of handling it that I can see. Frank has been after these guys on at least two forums. It is analogous to calling them liars because they can do something that he or you or whomever can not. There must be a lot of liars in his world. Brodie

B.E.Brickey

Attached Files

Sorry, I vowed to stay off the forum today to get ready for a trip and I guess I picked the wrong day. I didn't know things had gone off the track. I apologize. I will delete any further posts that are uncivil.

Several times on this forum I have asked that we all be tolerant and respectful of each others interest whether it is plinking, hunting, experimenting, or one or another of the competitive games. The CBA need all kinds of CB shooters. No one variety is any more virtuous than any other. This is a hobby for crying out loud. Aside from the interests of the CBA it is stupid and uncivilized to do otherwise.

That does NOT mean that we shouldn't disagree with and challenge one another's theories and opinions in a respectful manner. Without such honesty there is little use for a forum and we will never learn from each other. Since honest and civil disagreement is necessary we also should't always be looking for offense in every sentence either. I'm sure many fewer of these ugly outbreaks would happen if we were talking to each other face to face. We all have to be extra careful with the written word or misunderstanding happen.

Your cooperation would be appreciated in the future.

John

Attached Files

Larry Tim and Bjorn: Thank you guys for your contribution to the Cast Bullet hobby that I enjoy, Reading of your work with HV cast holds a particular interest with me. I'm not interested in organized match shooting but that doesn't mean I don't appreciate an accurate load, especially Hv loads. Keep up the quest Guys. Gp

Attached Files

New caster. Never done rifle only handgun. Really intrigued at the thought of a 3k fps boolits. If only because a friend of mine is all gaga over the new Hornady ELDX bullet and I know 300 yards is about his ethical limit even with a rifle and scope that costs more than I'll ever spend on a hunting rifle. The thought of doing it with a home grown lead bullet warms my heart.

Glad I suffered through the other stuff to see that tidbit.

Keep the HV stuff up.

Attached Files

Jeff, if you want to hunt at long range with HV cast bullets, the trick is to use a slow twist barrel, and a 30 caliber bullet. I actually think a 7mm would be better, but getting slow twist barrels in 7mm pretty much limits you to the top end custom barrel makers. If you go with 30 caliber, you can get a 1-17 twist barrel from Shilen for $200 that will put you right in the drivers seat for 3000FPS. Have it chambered in 30-06 (if you would like, I can do it and use the 30XCB chamber reamer so you get a tight .337 neck which helps a little). Then you go and buy the bullet I designed (with the help of LMG) that is for sale at NOE bullet molds. Use Hornady checks, White Label 2700+ lube and load good concentric ammo, and you can shoot deer at 300 yards no problemo. My personal recommendation for alloy is to use either Lyman #2 or cut Lyman #2 50/50 with pure lead. I have built quite a few of these rifles at this point, and I guarantee it works like a charm (of course, that's not a literal guarantee unless I personally build the rifle, but you get the point). It really is just that simple. Even if you screw everything up and use the wrong alloy, powder, lube, and stuff the bullets in crooked. If you are using a slow twist barrel, you'll probably still be able to make decent hunting groups at 2700 FPF. However, if you want to really roast the atmosphere at 2900FPS or faster and keep your groups less than 1.5MOA, you're going to have to pay a lot of attention to.........drum roll.......BULLET QUALITY. The closer you come to 3000FPS, the more bullet quality (or lack thereof) will start to bite you in the beehind. If you've never shot cast bullets faster than 2400FPS, then all this agonizing over bullet quality really doesn't mean much, but if you want to shoot Copenhagen can sized ten shot groups at 300 yards and in excess of 2900, you find out real quick that you begin shooting an excellent group at the casting bench. That's why there's some who claim bullet scrutiny is a worthless waste of time, while others make it their life's mission. It just depends what your objectives are.

Attached Files

I loaded 5, 5.5 and 6 grains of Titegroup with 60 gr. 225646 gc, lla bullets in 223, looking for a load of titegroup.

Enough for 5,5 shot groups each.

Also loaded 50 reject bullets for foulers, 5/titegroup.

I'll shoot later this week and see how the rejects do next to good bullets.

Attached Files

Joe: FWIW, TiteGroup out of my 223 Handi 24” 1 in 9 twist. Lee 55gr. Bator Gas checked and powder coated. 5.5gr Av 1927 fps Sd 19, 6gr. Av 1999 fps Sd 10, 6.5gr Av 2119 Sd10 and 7gr. 2261 Sd17. I've been looking over a few 22cal. moulds since loosing my fear of the small pellets. Makes a pot of lead go a long way. Gp

Attached Files

Joe: FWIW, TiteGroup out of my 223 Handi 24” 1 in 9 twist. Lee 55gr. Bator Gas checked and powder coated. 5.5gr Av 1927 fps Sd 19, 6gr. Av 1999 fps Sd 10, 6.5gr Av 2119 Sd10 and 7gr. 2261 Sd17. I've been looking over a few 22cal. moulds since loosing my fear of the small pellets. Makes a pot of lead go a long way. Gp

Today I spent 2 casting hours with the 4 cavity NOE 227-80. Inspection found 4 good, 50 bad-I melted them all. I surrender, I clearly don't know how to cast with aluminum molds. You can have the mold, for 100 good bullets cast in it. Or for nothing. John A. says it will stabilize in a 9” twist, it did in my Savage.

If you want the mold, PM me your address. I'm done trying.

joe b.

Attached Files

Joe, I would like to give that mold a try. I am really curious. And if I can't make it work I will send 100 bullets from my mold. Mine has cavities lapped to different nose sizes so I might have one that works in your guns. John

Attached Files

I find aluminum molds require lots of care to make perfect bullets. Give me a brass mold any day (from an excellent maker) and I'll have it behaving in no time. Iron would be great if anybody made one that had a smooth interior instead of machining marks that make the surface of the bullet look like it was threaded with a 100 TPI pitch. Yes, I know there are higher quality Iron molds to be had, but I have to step over brass molds in order to get them and I see no reason to do that.

Attached Files

Joe, Upon rereading your post I see that you were offering your mold to gpidaho. Sorry to butt in. John

Attached Files

No foul John, I always think of you as a gentleman and a friend here at the CBA. We've all had those frustrating casting sessions and maybe Joe will give it another try before passing it along to anyone, that's fine with me also. Thanks to all here for your help and kindness. Merry Christmas. Gp

Attached Files

The mold is off to GP in Idaho this morning. Maybe he'll let John and Ft. L. give it a try. I'd like bullets to try, but that's not important. The 225646 modified is working well-I cast 182 good ones after the 227 80 failure. joe b.

Attached Files

Good steel, Whilst I am happy to plink away,I would still like to shoot gc's at serious velocities,even of only now and then.I am not sure that at my age,73 YO, it is important,but I would still like to be able to do it.You suggest a 1/17 twist barrel,could I ask what cast bullet would handle that twist.Or more specific would say a 311041 or a RCBS 180 flat nose,work if the velocity was down around 2,000 feet/per/second.Today I shot with a 1/14 twist barrel in a Omark,using RCBS 150 SP GC ,and 45 grains of 2213 SC, Regretably, I an not able to post pictures,but with 20 shots on one target at 100 yards,the spread was 57.20mm vertical and 57.00 horizontal,but 15 shots were 25 mm vertical and 35 mm horizontal..This gave me a lot of confidence as we have a lot of gusty winds here as well as a lot of mirage and I had no wind flags.Plus the bullets were not weighed.Keep up the good work,the HV threads you and Larry put up are of great interest to me.Cast bullet shooting is a recreation for me,from serious competitive shooting,and I am past worrying about the perfect bullet.Today I felt that the bean cans were in danger.Just realized that I didn't mention that I am using a .308 Winchester calibre.Mike.

Attached Files

just as there are evil children, i suspect that the infamous 225-80 mold that haunted joeb will be passed on from caster to caster like a grinning zombie doll ....a year from now it will be advertised here monthly, and the previous owner will need to find unsuspecting new members ... probably have to include a couple twenties to boot to get somebody to pour hot lead into it's soul and reap the consequences ...

.....may have to try casting silver alloy ...

be aware ...

ken

Attached Files

Now you'll find goodsteel and I agree on a whole lot of things but the one thing we disagree on is about aluminum vs brass moulds. I'll take the aluminum any day. I've a lot of moulds of iron (Ideal, Lyman, RCBS, SAECO), aluminum (Lee, NOE, Rapine, TC, BRP) and brass moulds (MP). I also have a couple Iron moulds of unknown origin. Additionally, over the years I have used numerous iron, aluminum and brass moulds of various makes.

I have absolutely no problems with any of the iron, brass or aluminum moulds casting quality bullets. In 30 cal I use primarily two moulds for my high velocity loads; an iron Lyman 4 cavity 311466U and a 4 cavity NOE aluminum 310-1650FN XCB. Both cast very uniform and smooth bullets as proven out during the visual inspection and weight sorting. The rejection rate is very similar for both moulds. In .22 cal I use a 2 cavity Lyman 225462 mould. It also drops very uniform bullets.

I have one MP brass mould that drops excellent bullets of #2 and linotype alloy....that is after you beat them out of the blocks. The mould is supposed to drop bullets at ,311 but it drops thos alloys in the .313 - .314 range. Obviously if was cut for the COWW/lead at 50/50 alloy of which the designer is very happy. However, with that alloy the bullets are of varying dimensions bullet to bullet measured in the same place and many of the noses are slightly out of round. The visual culling for defects results in a large % of rejects. Weight sorting shows a tremendous variation. This is the only mould out of the 90+ moulds I have that does not cast quality bullets for their intended purpose.

My 4 cavity brass MP 227-60 mould on the other hand casts excellent bullets w/o problems.

As I have mentioned before and goodsteel also mentions the quality of the alloy is a must for casting truly uniform quality bullets for high velocity use or where the RPM Threshold is being pushed. I prefer COWWs + 2% tin and #2 alloys for this purpose. They should be HT'd or WQ'd to increase the strength of the bullet to resist deformation.

I've found cleaning the mould is of paramount importance also when casting quality bullets, especially the smaller calibers of .30 and under. Some here would have an absolute conniption if I told the simple yet effective way I clean all my moulds prior to casting. I used to live in high humidity areas and rust was a real problem if the moulds were not oiled after every use. That always caused a problem with bullet quality when using them again. I developed the method I used based on the advise of a metallurgy engineer who worked for Boeing. It is easy and fast and quality bullets come easy as soon as the mould of aluminum, brass or iron comes up to proper casting temperature. I have helped many others over the years with this method on moulds they could not get to cast good bullets with.

I fully understand that there are defective moulds from all makers. I am not referencing any defective moulds above. I believe the problem with the 30 cal Brass mould is bullet design related and not mould related.

For all around use I have no preference over the material the mould is made of as I find all 3 materials can produce the same quality of bullets all other things being equal. However, I do find the lesser weight of the aluminum moulds to be a benefit (as I grow older) during a long casting session.

LMG

Concealment is not cover.........

Attached Files

FM LMG >>>Some here would have an absolute conniption if I told the simple yet effective way I clean all my moulds prior to casting. I promise no conniption. What is it?

Attached Files

I am easily offended so probably will have a conniption or two or even a hissy fit, but I would like to know as well. Why the mystery? John

Attached Files

Me too. After all, a good conniption not and then never really hurt anybody.

John Carlson. CBA Director of Military Competition.

Attached Files

Don't tell me you wash them thoroughly in Makers Mark after filtering it carefully through your kidneys.Whether you do or not, nobody should be shocked after that mental image. LOL! :wow:

Attached Files

Okay......

With the mold blocks on the handles with sprue plate attached I spray with carburetor or break cleaner and scrub with an old but still stiff (no Viagra jokes please)used tooth brush. This may take a couple sprays of the cleaner as it evaporates quickly. I scrub the block faces parallel to the vent lines and in the cavities. The top and bottom of the sprue plate is equally scrubbed.

Then rinse again thoroughly with the cleaner and let dry for a few minutes. The warmer the ambient temp is the quicker cleaner will dry. I do this outside over a 5 gallon bucket as the fumes can be obnoxious. Although in the winter I have done it in my garage over the bucket. Also do not do this anywhere near an open flame or while smoking. This doesn't take long, probably less time on a fours cavity mould than I've taken to type it.

Now here's the conniption part; use a hand held propane torch with the flame adjusted to a little over medium strength to play over the surface of the mould. I usually do the block faces and cavities first, the sprue plate next and then the outside. Apply just enough heat so you sea the “moisture” come to the surface and evaporate.......it is not necessary to apply any more flame/heat to the surface after the “moisture” has evaporated. If the “moisture” bubbles and boils off you are applying too much heat. You want the “moisture” to just come to the surface and then disappear. Go slow with the flame/heat so you can see the “moisture".

Let the mould cool and then swipe out each cavity with a q-Tip. Then apply what ever mould prep you use and the mould is ready to bring to temp and cast.

This whole procedure goes fast as I mentioned. It takes less time to do than to type or read this post. I usually set the cleaned and prepped mould over the top of my Lyman Mag 20 to heat up while the alloy is melting. It then takes very few casts, usually 2 -3, and perfect bullets begin dropping out. Many times perfect bullets drop out of those first 2 -3 casts and many times I use them too.

I also will corner dip the mould in the brought to temp and fluxed alloy to pre heat the mould with other types of furnaces. I've never used a warming plate.

Once the above is done on aluminum or brass moulds there is no need to oil them after use. I will usually dry brush the block faces with a clean dry tooth brush and Q-Tip the cavities before additional uses. The iron handles, if used on those blocks should be oiled but won't need to be cleaned before re-use.

With iron blocks in humid climates, or if not to be used again soon, the mould blocks and handles should be oiled after every use to prevent rust. I favor Kroil for this as it cleans off very quickly with this procedure.

So that's my procedure. It's easy, quick and I have yet to find a mould of iron, brass or aluminum it did not work on. It is the “moisture” that does not get cleaned off with the boiling and scrubbing methods that causes one to cast a seemingly endless amount of bullets before getting any good ones. This is especially true with smaller caliber cast bullets such as the .224s of this thread. They do not hold much heat as larger caliber/heavier bullets against the same size mould blocks used for each. Thus it take a lot longer for the smaller bullets to burn off that “moisture", even with aluminum blocks.

LMG

Concealment is not cover.........

Attached Files

lg:: my system of pre-casting prep starts out the same ::

i use crc brake cleaner and a toothbrush ... then spray again with the brake cleaner .

i don't use a torch tp pre-heat; but dp lay it on the pot ...if aluminum i usually dip a cprner in the hot hot hot melt.

if the cavities are a large volume compared to the blocks it takes less heat soaking and fewer reject castings to achieve good ones.

and here in humid iowa i oil iron molds after use. leaving castings in the last throw isn't good enough. but then it might be 3 years before i use that mold again ....

oh i recommended crc brake cleaner to john a. to clean after honing out a mold... apparently it just de-greased the grit and left it in the cavities ... so perhaps universal truths aren't so universal ...

ken

and for long term storage i like FLUID FILM ... get it at napa ...

Attached Files

I squirt Dawn Dishwashing detergent all over the mold and scrub with a toothbrush till the water will not break on the surface. This means there is no oil of any kind on the mold, but there may be other contaminates, so I then mount the mold blocks on the handles, fill an appropriate sized cup with alcohol, and submerge the mold in the liquid while the pot is heating up. After about a 10 minute soak, I scrub with a new brush (which soaked in the cup with the mold). I scrub, then swish about 2-3 times then blast the mold clean with an air hose. The only problem with my method is that the mold is now “chemically clean” on a molecular level, which is the perfect scenario if you want to solder something. In order to prevent the lead from trying to stick to the mold, it is necessary to heat cycle it a few times on a hot plate so the mold will form an oxide layer that the lead will NOT stick to. This sounds really involved, but it only takes about an hour. Still, I think I may try LMG's method next time. He's accomplishing the same objective.

Attached Files

ONce I have initially tuned, cleaned and then cast with a mold, after use, brought into the house while still HOT. Let cool until blocks are still warm. Remove blocks from handles, and immediately place the blocks into a (good sealing) GIammo can in which there is also VPI paper. I have stored my mold blocks this way for 60 yrs. NO Rust, AND NO oil etc to remove prior to next use. The molds are ready to go out of the ammo can. Prewarm and go for it beltfed/arnie

Attached Files

Warning the moulds to just under casting temp. on a solid top hot plate after cleaning gets “the good ones” dropping by the third try for me. Best way I've found to warm the moulds. Gp

Attached Files

When casting with a bottom pour pot, spout “flow rate” is very important. There is a sweat spot. On my RCBS I leave the locknut loose and turn adjustment screw by hand until I find it. Lead level in pot will change flow rate also.

Attached Files

When casting with a bottom pour pot, spout “flow rate” is very important. There is a sweat spot. On my RCBS I leave the locknut loose and turn adjustment screw by hand until I find it. Lead level in pot will change flow rate also.

Spot on. I do the same with my Lyman Mag 20.

Adding alloy to the pot keeping at a +/- where the flow rate remains constant is also one of the ways I do the same.

LMG

Concealment is not cover.........

Attached Files

Mike H

The 17” twist is the slowest that adequately stabilizes the 30 XCB bullet (NOE) at HV. It will not stabilize the bullets you mention at those lower velocities. Your 14” twist will do just fine for those. I do get very good accuracy at 2500 fps +/- with the 311041 in my 16” twist 3060 XCB.

Good to hear of your success.

LMG

Concealment is not cover.........

Attached Files

A whole lot of interesting postings here--thought I'd throw mine in.

I also use the warming shelf while the Lyman BP is coming up to temp. Than, I take the mold and heat it with a hot air gun I used for model airplane's. The warning on it says “350 degrees” and it's hot enough you don't want to touch the business end. I spend most of the 2 minutes or so on the cavities, and the sprue plate. Usually, after I've used this on the mould, it's ready to go, and the first castings are good. (Or at least as good as I can get.)

Another large benefit: In the winter, I “help” the Lyman sizer warm up by playing this hot draft over the die area, as well as the reservoir. Big help in getting the lube to flow.

Bill

In theory, there's no difference between theory and practice. In practice, there is. My fate is not entirely in Gods hands, if I have a weapon in mine.

Attached Files

LMG, Thanks for your reply,I was starting to think that I may have caused some confusion by asking about 2,000 fps loads when the emphasis was on higher velocity ,but you have worked it out for me.I would like to shoot at higher velocities,but not all the time,so a very slow twist barrel would not handle the heavier bullets I have at medium to slower velocities.I will work with the 1-14 twist for the moment,as I see it,the main consideration is to get the chambering and throating matched to the bullet. When I think of the tribulations I have had over the years trying to get accuracy with a bit of speed and failed,the developments you have been working on are an eye opener.Merry Christmas to you and all the the Cast Bullet Forum people.Mike.

Attached Files

Mike H

Can you get NOE Moulds? The 30 XCB and the 311466 are the best bets for top end velocities in the 14” twist .308W. I've been testing my own 14” twist .308W with 27.6” barrel for several years before I had goodsteel barrel a very nice VZ24 with a 16” twist Broughton barrel and chamber it in 30x60. I still shoot the Palma rifle though as it is easy to load HV for.

The first thing I learned in this HV quest though, which is the crux of this thread, is that the bullets must be the best we can cast. Even though I had been casting some excellent bullets for years that shot really good at the usual 1500 - 1900 fps range it took a bit of learning to re-learn how to cast really excellent bullets and how to properly inspect and weight sort them I'm still learning.

I just this last week cast about 500 30 XCBs. My visual inspection and weight sorting have rejected about 30+ % of them for HV use. The majority of those rejected bullets would shoot 1 1/2 - 2 moa in my .308Ws and 30-06s with 10” twist in the usual 1500 - 1900 fps range but they just don't cut it for HV. There isn't a single one of those rejected bullets I wouldn't have found suitable and used not too many years ago. Yes, I am still learning what HV with cast bullets really takes. One thing for sure that joeb is right about; it takes the best bullet we can cast.

LMG

Concealment is not cover.........

Attached Files

LMG, I could get NOE moulds here,just haven't done it.It appears that my casting and inspecting will need more scrutiny,I have been pretty relaxed about it,throw the really bad ones out and when seating the gc's,put the visually best in one pile and the others to what I call,semi rejects,into another.The fact that about 75% of the loads!whether 30 or 22 cal,go into a reasonable core should be telling me something.Mike H.

Attached Files

The fact that about 75% of the loads!whether 30 or 22 cal,go into a reasonable core should be telling me something.Mike H.

I would be very careful about concluding that because 75% of your bullets go into a “reasonable core” that it is telling you that the other 25% are on the outside because of small defects in the bullets. The finest jacketed bullets which are far more uniform and defect free than our CBs usually have similar patterns. That is just the nature of a group. Some have to be on the outside.

This idea is just a variation on the false idea that the worst shot in a five shot group is usually caused by a bullet defect. This is possible but actually defective bullets cause a small minority of the fliers we see -- no matter how tempting it is to suspect that it is a defective bullet.

To find out, make up a bunch of 15 of your most perfect bullets plus 5 of your “semi rejects” and shoot three of the perfect then one of the SR. Repeat until you have a 20 round group while keeping track of where each type landed. I think you will find that the majority outside the “core” are more likely to be your “perfect” bullets. The idea that defective bullets are the cause of most fliers is one of our favorite CB theories that can be fairly easily tested to see if there is anything to it.

John

Attached Files

John, When it cools down a bit,I will try your idea.

Attached Files

But if it isn't the bullets, and it isn't the equipment, then.......................................:doooah:

John Carlson. CBA Director of Military Competition.

Attached Files

But if it isn't the bullets, and it isn't the equipment, then.......................................:doooah:

There are a huge number of factors that prevent bullets from going through one hole. Rifle and shooters quality perhaps provide the most and wind and mirage are alleged to sometimes cause less than perfect results.

Cast bullet quality is only one of the many candidates but for some reason many shooters immediately assume that the fault for a “flier” is the bullet. There are no decent test reports that I have ever seen that offers the slightest bit of evidence that small defects or small weight variations are the usual culprit for having one or more shots outside the “core” group.

Aside from physical causes once you agree that all shots won't go into a single hole we are talking groups. Groups come with some shots at the edge. One shot by definition has to be the worst It is very rare to have a group that one of the shots didn't make bigger. That's the nature of groups no matter how perfect the bullets, rifle, and shooter.

It is truly amazing to me that with all the possibilities so many shooters think that “fliers” are caused by bullet quality without a shred of evidence that that is the reason. John

Attached Files

But if it isn't the bullets, and it isn't the equipment, then.......................................:doooah:

It IS the bullets and it IS the equipment and it IS the conditions and it IS the shooter. So we try Lapua cases and weigh powder and inspect bullets and buy $350 bench rests and develop precise barrel cleaning regimens and switch powders and change primers and trim cases and de-burr flash holes and orient bullets.

And with a rifle that averages 1.5” for 5, five shot groups-not one of these “accuracy tricks” has been shown to reliably reduce average group size. Use all the tricks? Yes, accuracy improves some, sometimes-but an unmeasurable amount for each trick.

Big accuracy changes come when big changes are made-new gun or new barrel or new scope or new caliber or new mold or ...

Attached Files

It certainly is a question or problem,depending on how you look at it,if the same rifle and the same shooter over a reasonable time or number of shots,is able to shoot groups with match quality jacketed bullets that are far more uniform and smaller,than cast bullets,we are left with either the inability of the operator to find a load for cast bullets,but can do it with jacketed,or that there is a problem with cast bullet uniformity.All I am trying to do is have fun and with the interest in higher velocities for cast gas check bullets,I would like to speed things up.Mike.

Attached Files

In my humble opinion, the #1 thing that makes small groups at any velocity possible is barrel quality, and cast bullets show barrel quality better (or worse as the case may be) than jacketed bullets. There are no punches pulled with cast bullets. If something is not quite right, you'll see it on the target, and it gets worse (much worse) as you shoot faster and faster. If you are shooting faster than 2700FPS with a match grade rifle built to exacting standards, and a good shooter is behind the rifle, and the brass has been prepped with the normal match grade tricks, and a good load has been established, you certainly will see a difference in bullet quality! In fact, bullet quality becomes the main thing you war against to maintain consistent groups.

On the other hand, if you're shooting a store bought Savage, and you're just trying to make something happen at 1900 FPS that looks like a group, there is so much static in the system with the quality and design of the bore, chamber, action, stock, trigger, rings, mounts, brass, and alloy bullet quality is like trying to listen for a tick in the engine of your pickup truck when you're rolling along at 70 MPH with mudgrip tires and a bed full of beer cans. Put the same tick in a new Cadillac coup, and it will drive you nuts. The guy in the truck hears the guy in the Caddie complaining and laughs at him. Different strokes. Not that I have anything against Savage rifles nor the people that shoot them. All I'm saying is that at low velocity, you can get away with a lot of things that will kill your groups in the cradle at HV.

Attached Files

Mike, I respectfully disagree with your statement that only two possibilities are left. Joe's post has a good starting list. I would add bullet design and variations in bore condition from shot to shot and that would still be an incomplete list. I think Goodsteel nails it with his pickup truck vs Caddilac analogy. Bullet uniformity gets lost in the noise of all the other more important factors.

But make no mistake most fliers are out there because in any group some have to be on the outside. Read my Fouling Shot article that includes Landcasper's twenty five shot group and stare at the individual five shot groups for awhile. I think that make it easy to see.

In their efforts to improve accuracy and eliminate fliers, cast bullet shooters seem to be obsessed with chasing uniformity of bullet appearance and weight, powder weight, case weight, neck tension and a bunch of other things that “seem reasonable and logical,” -- but have never been verified by testing. Some say that it gives them “confidence” and it may make them feel better but they almost never test to see if any of these things make the slightest difference in either the size of their groups or the number of the dreaded fliers they get. Why is that?

I don't know why that approach is so popular, but I have theories. One is that the human animal is perfectly happy operating on faith and what he perceives as “logic” and has minimal interest in using anything resembling the scientific method to see if his cherished beliefs have any truth in them.

When the weather get cooler, I hope you will follow up on running the test I suggested. What you find from two or three 20 shot groups would make a good article in the Fouling Shot. The only way to settle such differences of opinion is testing.

John

Attached Files

Mike H: Come on out to Idaho for a visit, it's plenty cool enough here already and I'll put you up. Jokes aside, adding the extra Jokers to the deck is a big part of why I shoot cast. It certainly hasn't saved me a bunch of money. For me it's the frustrating fun of making a malleable little pill fly strait when odds say it shouldn't. Gp

Attached Files

As a match shooter, I fail to see the point of trying to prove that bullet quality doesn't matter much.

If you shoot in matches and I believe a majority of people on this site do, you probably cast at least 1000 bullets a year. That's enough to become good enough at it, that you shouldn't be casting wrinkled bullets, for sure. With inspection (you have to do that, regardless) you can see the smaller imperfections (like rounded and unevenly filled out bands) and work thoughs problems out (with help if need be).

As for myself, I'd have a ethics problem, incouraging people to shoot sub standard bullets for anything other than sighting in.

As I said before, I've shot “foulers” into the same group but, they don't always make that group, either (neither do my good bullets) but, once you pull the trigger, you can not get that bullet back. Now, that's the technology we need to be investigating :)