Some molds like the alloy hot but take a long time to cool down, slowing the process. Lowering the thermostat affects bullet quality. So, I keep the alloy hot and cool the bottom (or sprue plate) of the mold, a little bit, on a wet sponge set in a saucer of water. This helps me cast good bullets fast. But, water in the casting area is a danger. Just a drop of water in molten alloy makes an impressive explosion. A safe way to cool the mold between pours is to cool the mold bottom on an aluminum plate or muffin pan. Dick Howes, one of the better offhand shooters at the Old Colony Sportsman's Association, was able to cast bullets fast by having a sponge in a shallow dish of water in the casting area, and pouring-cooling the base of the mold on the wet sponge-removing the bullet-pouring-cooling... He said that the problem in casting fast is keeping the mold cool so that the bullet hardens quickly. (Ken Mollohan's Note: I have had good success using a damp cloth (actually, a clean but discarded bath towel) to rest gang molds on. The cooling is effective, the working area is generous, and there is no liquid water readily available to be a hazard. The damp towel approach also does a decent job of cooling the heavier bullets enough for handling in a reasonable length of time. It also has the advantage of provide the fast, cheap cooling of water without the hazard of explosions from liquid water: when it begins to dry out, just stop long enough to re-wet it at the sink and wring it out before resuming casting.) A. C. Gould, in “THE MODERN AMERICAN RIFLE”, recommends cooling the bottom of the mold in a dish of water between pours. He talks about a person who could cast 12 perfect .45 caliber bullets in a minute, 505 in an hour. This is 30 pounds of 500-grain bullets. I wonder, could A. C. have told a fib? Maybe not. Several shooters on the Internet cast bullet forums report cooling the sprue plate on a wet sponge or rag to cool the mold, and casting lots of bullets quick. Bruce Bannister, on the “Cast Boolits” forum reports: “In one timed run at my normal rate with a SINGLE-cavity Lee .30 mould, I made 159 good bullets in thirty minutes. This translates to over three hundred per hour from a one-banger mould. It's not unusual to get well over 500 good 'uns in an hour from my Lyman or RCBS two-cav jobs, and 400 'bph' is easy. Lyman four-cavity moulds can give me over 1000 per hour on a good day. Casting heavier bullets takes a bit longer due to longer mould-filling-time than is required by lighter boolits."

COOLING THE MOLD

- 13K Views

- Last Post 21 October 2019

The casting 5 or 6 times then cooling is just what I tried the first time I tried to learn with a 6 cavity mold. I did get to a point where I thought I had a good balance and was getting good bullets the first pot-full. A couple more sessions casting that way seemed fine too.

Unfortunately some simple testing and weighing showed a wide variation in bullet weight, diameter and bullet hardness.

That cooling every 5 or six drops shrank the bullet diameter till the mold warmed up again. Close examination under magnification also revealed rounded instead of sharp edges on lube grooves and bases from the cooler mold pours. The hotter pours also had the bullets catching up to correct diameter and heaviest in weight. The biggest concern came when I did hardness testing and found that BHN was all over the place. This combination from testing made the decision that the 3 batches of bullets were actually the worst bullet casting I had ever done in over 50 years and I was furious.

I melted them all made new ingots with warm molds and slow, even air cooling so BHN was steady again for all ingots and started over after I figured where in my casting cadence I should slow down to get the hot mold issue solved.

The next casting session with a fully warmed mold, I started differently. I bottom poured with a large puddled continuous pour for all 6 cavities and watched for the first sign of crystallization in the huge sprue puddle. After that I counted to 6 and the sprue cutter plate opened easily with no smearing. Here is where I changed, with the sprue cutter plate open, I paused a wristwatch monitored 20 seconds before opening the mold and dropping bullets. I also tapped the large sprue directly into the pot, then closed the mold and poured immediately.

This rhythm is currently still the same one I use with my 6 cavity mold, I had concern about dumping the large sprue right back into the pot lowering pot temperature but with continuous running this way there was no significant swing on the thermometer as I was bottom pouring immediately and returning the sprues at the same rate.

My bullets tested very much better for evenness of diameter size, fill-out, weight and hardness. Casting this way also left no big pile of large sprues for the next session and I could cast the whole large pot-full ( about 17 pounds in my Lee 4-20 ) down to 1 inch in the bottom without stopping or fluxing at all. The bullets were much better for me this way than the bullets cast with mold cooling every 5-6 pours.

Gary

Attached Files

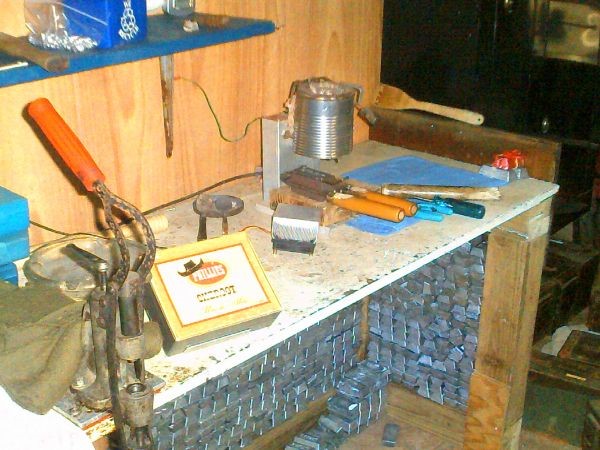

Hey Duke M This is my new improved set up. An appreciative recipient of innovation, gifted the sink/fan combo to me. His total cost was $0 due to a relationship with our local scrap dealer. My rig is a computer power supply heat sink with an integral fan. Normally powered with converted AC it is simple to hook up to a cel phone AC/DC charger. Empty .22 rimfire cases fit into fan attachment holes for clearance allowing air intake. For me, two long rifle cases at the top and two short cases on the close end provide a slight angle and improve ergonomics. In service now for multiple casting sessions, it is so efficient, the additional small fan for cooling sprues has become superfluous. Semi-extensive testing has shown it effective for single and double cavity moulds as well. Soon I will explore the use capabilities of this on moulds larger than shown.

Shoot often, Shoot well

Attached Files

Footnote For some of us, our casting area may be use specific and we have concerns of space utilization. My cooling system takes up what a Lyman 4 cavity mould requires, needs no refill regardless of use quantity, doubles as a mould rest, no bench hot spot, no steam, consistent empty mould temperature, easily replicable, inexpensive, durable, and doubles as Neanderthal repellant. See in the photo how much “clutter” my system forces one to sustain. The dedicated casting area I work in, has been refined to a state of efficiency that requires a relatively small amount of my reloading/man cave. For nearly thirty years now, 2500 projectiles per month has been my average production. This number is based solely on primer purchase receipts. Countless amounts of my bullets have also been purchased and gifted throughout the years.

Shoot often, Shoot well

Attached Files

Getting the thermodynamics of casting to work is a balance. There is no perfect way that works for everybody. I've never really had to use cooling at any point in my casting except the first time I tried a 6 cavity mold. I eventually worked out my timing and pot temperature so I could cast with the 6 cavity and not use cooling. It took some thinking and applying my observations of my own methods to figure where in my casting cadence I had to change, but I got it. I prefer to cast without cooling as I personally see cooling as a variable that I have insufficient control over and mold cooling, for me, dramatically effects the BHN of my bullets and the fill-out of the bullets giving them wide variance.

I'm sure some control that variance way better than I can. I have a balance that works for me and I can maintain pretty even fill-out and BHN of my bullets from a 6 cavity mold... The 6's are much more challenging for me, yet I have certainly read that some casters consider them the easiest to work with!

I cast over 50 years with only 1 and 2 cavity molds before I even tried a 6 cavity mold. I am sure some casters start with 6s and have a ball with them. It wasn't easy for me to make the move, but I got it working.

There is a WIDE variance in methods that will work for usable bullets. My first lead round-balls when I was 6 years old, I cast screaming hot lead into a cold mold. The lead was so hot it was hot enough to warm the mold sufficiently before the lead even began to solidify at all. It worked! It worked just like the guy I copied, Davey Crockett in the books and movies.

Gary

Attached Files

Guys

All the above described methods work. I am a bit surprised with the experience available, you are still working the neanderthal methods. The small fan does a fair job but the base is a bit harder to cool evenly with a fan. Top of the line is an aluminum finned heat sink from an old style amplifier, coupled with a small fan. For an easy adaptation, a large empty coffee can works well as a heat sink. No steam, always consistant and no need to maintain moisture level. Steel blocks will suffer when using water in any way.

Aluminum finned heat sink from an old style amplifier is easy to get and generaly is attached with only a few fasteners. Fins down, the backs are flat and make good contact with a mould. A small fan pointed at the rest will also cool the sprue quickly.

The coffee can trick is cheaper but requires most bottoms to be thouroughly flattened for good mould contact, to be efficient.

I use both of these cooling methods depending on the situation at hand. The aluminum finned heat sink from an old style amplifier is the most efficient for large cavity casting and I use the coffee can method for my smaller cavity casting. Two mould service is my preferred disipline and I produce huge amounts of very high quality projectiles during a session.

Do yourselves a favor and get set up with one or both of these systems. It will increase your production and you will thank me the first time you knock either one over.

Roy

Shoot often, Shoot well

Attached Files

I am the kind of neanderthal that sees all your heat sink gimmicks as a junk pile that is unnecessary at all if you have the patience to use a modicum of understanding temperature flow in casting cadence and have the modern man intellect to ponder thermodynamics in casting to the degree that allows you to see logical simple answers are the best answers, not a junk pile of fan and heat sink.

You will probably cut yourself on that junk pile or even knock something important over trying to avoid bumping the junk pile on your crowded bench during casting. Name calling with the thoughtless derogatory word Neanderthal is antisocial too. You are not funny either.

I challenge you to a duel.

Gary

Attached Files

Guys

All the above described methods work. I am a bit surprised with the experience available, you are still working the neanderthal methods.

Roy

Neanderthal? Hmmmmmmmmm. I find that rather presumptuous of you to say considering the company you're in. Let's play nice. This is just an informative topic with different people sharing different ideas. No need for cynicism.

Pat

If someone else had of done to me what I did to myself . . . I'd have killed him. Humility is an asset. Heh - heh.

Attached Files

I have found the use of a clock with a large easy to see second sweep hand to greatly reduce weight variations. I watch for sprue puddle to “turn"..then start counting..usually 5 sec. for .22 thru .38.

Attached Files

Hey guys

Well it has been over four years and +100k castings since insulating my little Lee 10# pot. The heating element would have burnt out at least once in factory issue. Still going strong but past experience has me listening for the tell tale hum. Nothing yet.

My cooling system has now proved itself through empirical substance. Stable and consistent empty mould temp is but a single constituent to high quality casting. Removing heat from a casting is not just a good idea, it is mandatory. The best path would be low velocity free fall, not possible with current technology. Next is to create a convective flow path for the heat exit. Ambient air will adulterate, the rate will be subject to the ambient temp. For some, casting is a therapeutic experience and air cooling is part of the perflaxation sought. If expediency is an attractive option, the aforementioned practices will improve production. Any inconsistent routines will introduce inconsistencies into the finished product. (" if you have the patience to use a modicum of understanding temperature flow in casting cadence and have the modern man intellect to ponder thermodynamics in casting to the degree that allows you to see logical simple answers are the best answers"). This attitude would also limit us to walking as the best answer to transportation issues. Producing projectiles which challenge the skill and abilities of man and machine require a little advanced thinking. That is how we got modern smokless propellants. Doing this at a higher rate of quality and production is the reward for those who wish it. My projectiles produce gold medals at state level competitions, for myself and others.

Recently a shooting competitor struggling with some inconsistencies in his cast weights came to me for a diagnostic appointment. He is part of a group of respected shooters who are experienced bullet casters. There were two fellows involved in the conundrum. Good looking castings with wide variations in weight. Checking the moulds showed nothing obvious. So what the hell? I fired up my rig and sipped some casting juice while waiting for temp. With everything warmed up I dropped the first four cavities, set the block onto the heat sink for 5 count, then broke the sprue and out they came. What I assumed was common knowledge, seemed to not be the case. Both were taken aback when on the next pour I cast in the opposite direction. There was nothing else to explain. I thought everybody knew this!

Gary, as to your challenge, I got gold in Florida State NRA hunter pistol, Big Bore Iron sights 2004, 2005, 2006 and moved on to more challenging competition. DA.

Roy

Shoot often, Shoot well

Attached Files

I am coming late to the party here, but LOVE the discussion.

Over the years I have tried all of these methods, and these days if using a single gang mold I use a small box fan on the casting bench and rest the blocks directly on the enameled metal table top and try to pace myself to maintain a consistent casting temperature.

But the great majority of the time I alternate between two molds, of distinctly different shapes which are easily separated, and work up a pace which keeps them both going. That is my preferred method.

73 de KE4SKY In Home Mix We Trust From the Home of Ed's Red in "Almost Heaven" West Virginia

Attached Files

I have a 20 lb Waage pot and have ladle poured for quite a number of years . And for most of my molds except for the steel nose pour blocks, usually run the pot temp between 700-750 degrees. I set the mold blocks on the top rim of the pot to preheat. Over time, I have worked out my own procedure and routine for casting that works for me depending on what mold I'm using at the time. Just as everyone else does

However. last summer I bought an NOE digital mold block thermometer that uses a probe connected to a digital readout. This probe is inserted into a hole that is drilled into one side of the bullet mold causing the temp of the blocks to be continually displayed on the readout.

It took some getting used to but once we got acquainted, I'm beginning to like this gizmo more all the tiime. First, there is no guessing as to when the cold mold is up to the proper temperature and then casting untill I get good bullets. With some use at the beginning, this is determined by casting to find the temperature range that the mold needs to be.. Then, that temp. is maintained on the digital readout by controlling the cycles. No guessing about when the mold is hot enough to start or maintaining the right temp. when casting.

Right now, anyway, cooling the mold is less of a problem than it was before because I can control the mold temp as I cast. No doubt , when summer arrives once again I'. have to adjust my routine some what. ..

Attached Files

The NOE digital thermometer is good learning tool, especially when pre heating mold before casting. It also tells you if you are casting too slow of too fast. You must find the perfect temp and stay around it. My mold temps have reached lower 400 degrees to get good filled out bullets, but most every mold is different.

Attached Files

I guess there are just about as many casting methods as there are Bullet Casters.

I clamp 2 20lb bottom pour pots at either end of a picnic table. as soon as 1 gets down to 1/4 full, I refill it and switch to the pot at the other end. I stack 15 1lb ingots on the back of each pot and use the warmed ingots to refill the partially emptied pot. I keep a hot plate in the middle of the table with a cast iron diffuser plate to rest the molds in use on. I try to keep it at 350+degrees. I also keep a fingernail fan at each end too. It takes less than 5 min. to accomplish the change from one end of the table to the other. Even though I'm outside on a covered patio I keep an oscillating fan on high. I get 700 -900 an hour this way. But now I'm getting too 'advanced in years' to maintain the all day pace.

I cast from 3 2cav molds, or 2 4cav molds. Or even 4 1cav molds. I always use the same brand of molds and close in caliber/ weight as practical. I use the “back to front", “front to back” method when using 4cav molds too.

I use a counting/deep breathing method of cooling. I open the mold, drop the bullets and take and let out one or two deep breaths before I close & refill the mold cavities. This sounds weird but it works for me.

Long time Caster/Reloader, Getting back into it after almost 10yrs. Life Member NRA 40+yrs, Life S.A.S.S. #375. Does this mean a description of me as a fumble-fingered knuckle-draggin' baboon. I also drool in my sleep. I firmly believe that true happiness is a warm gun. Did I mention how much I HATE auto-correct on this blasted tablet.

Attached Files

I've never used a NOE thermometer as I don't yet have a NOE mold. But I have stuck a dial type casting thermometer in a mold cavity as a mold was preheating on the hot plate. I turn up the hot plate until the mold "temp" reaches about 300+ degrees. Then I start casting. That hot plate can be tricky to use, turn it all the way up & it'll melt a sprue left on the cast iron diffuser plate I use with it.

I also use a "nail" fan for sprue cooling. I just set the molds down on a wood bIocker in front of the fan. I cast from 2-3 2cav molds from the same brand, or 1-2 4cav molds. I use a bunch of the old LYMAN/Loverin 1cav molds for rifle shooting. I have to cast HOT & FAST to get good bullets from them. I also find mixing molds from different makers throws off my casting rhythm. However I'm learning to like the 6cav LEE molds. I'm saving my pennies to get a new 4+ cav mold from one of the new mold makers, maybe NOE or ACCURATE.

Long time Caster/Reloader, Getting back into it after almost 10yrs. Life Member NRA 40+yrs, Life S.A.S.S. #375. Does this mean a description of me as a fumble-fingered knuckle-draggin' baboon. I also drool in my sleep. I firmly believe that true happiness is a warm gun. Did I mention how much I HATE auto-correct on this blasted tablet.

Attached Files

WOW

Time does fly. Went out to fire up everything this morning and nothing seemed out of sorts at all. In the usual twenty minutes or so, thermometer showed mould blocks ready at 395*F, heat sink at 72*f and ???casting pot at 68*F???. Upon close observation, and turning the radio down, the tell tale humming of a burnt out heating element. DARN!! Insulating the Lee pot had extended the life of the element to the point of complete complacency. Eleven and a half years on the same element is almost three times my past average. Oh well, the project for today has been changed.

Just for the benefit of those whom will appreciate it, I will expound on a tip offered earlier in a rather abstract way. In projectile casting, weight can be fluctuated simply by manipulating casting temperatures at various points. With the exception of single cavity moulds, alternating fill direction on each cycle, will narrow weight inconsistencies. The more cavities involved, the greater need for alternating becomes. Failure to alternate will cause one end to become hotter through dwell. Again, for those whom will appreciate it.

Roy

Shoot often, Shoot well

Attached Files

You can also use ingots of bullet metal as heat sinks for extended casting sessions. Simply rest the hot molds on the cool ingots as you reach for the next mold when you're casting in tandem. After a while, the ingots will get hot, so feed them to the pot, and set out new, cool ingots to take their place. Unless of course it's necessary to cast at breakneck speed, then you can use the damp cloth routine. BTW, a drop of water needs to be introduced below the surface of the melted lead to cause a steam explosion. A drop on top of the melt will just skitter around on the surface, the same as if it were in a frying pan.

Attached Files

When casting heavy .40 or .45 rifle bullets, I use a large block of aluminum or copper & hold upside down mould against this for a few seconds.

Attached Files

I agree with Onandaga (Gary) in that there are a number of ways to cool a mold. I run my pot temperature at 345 degrees celcius (653 degrees F) for all my casting. (Love my PID!) That happens to be the sweet spot for me. Once the mold is up to temperature I find (depending on the weight of the bullet) I may need to leave the mold open for 10 - 15 seconds. Again, depending on the weight/size of the bullet. The smaller 125 grainers I can usually keep rolling at a steady pace. The big 300 grainers require that I hold the mold open for 15 seconds between casts. I'm not in a big hurry when I cast. I enjoy taking my time, having a beer and enjoying the art. Pat Reynolds

If someone else had of done to me what I did to myself . . . I'd have killed him. Humility is an asset. Heh - heh.

Attached Files

Two things have improved the quantity and quality of my cast bullets in the last 10 years. A hot plate for pre-heating and a small fan, for cooling. I use both a hi-speed squirrel cage fan, ala the Master Caster and a manicure fan as recommended by Mike Venturino.

Duke

Attached Files

Categories

- All Categories

- General Polls

- Contact Us w/ Forum Issues

- Welcome to The Cast Bullet Association Forum

- General

- Bullet Casting

-

Guns and Shooting

- AR Platform

- TC Contenders & Other Single Shot Handguns

- Shotguns

- Informal Matches & Other Shooting Events

- Gunsmithing Tips

- Gun Cleaning & Maintenance

- Optics

- Benchrest Cast Bullet Shooting

- Military Bench Rest Cast Bullet Shooting

- Silhouette Shooting

- Postal Match Cast Bullet Shooting

- Factory Guns

- Black Powder Cartridge

- Hand Guns

- Lever Guns

- Single Shot Rifles

- Bolt Action Rifles

- Military Surplus Rifles

- Plinkers Hollow

- Muzzleloaders

- Hunting

- Reloading

- Buy, Sell or Trade

- Other Information & Reference

Search

This Weeks High Earners

-

wimilkman

30

wimilkman

30

-

pat i.

18

pat i.

18

-

Tom Acheson

14

Tom Acheson

14

-

Aaron

12

Aaron

12

-

BRatigan 10

-

MarkinEllensburg

9

MarkinEllensburg

9

-

Ed Harris

8

Ed Harris

8

-

mashburn 6

-

porthos 5

-

MP1886 4